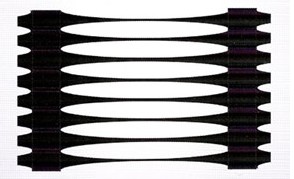

Miragrid Gx High Quality HDPE Uniaxial Geogrids

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 100 million Square Meter Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of HDPE Uniaxial Geogrid:

1. uniaxial Geogrid

2. ISO 9001:2008 certificate

3. Strength:25 to 180KN/m

4. Width:2.5m,3.95m,4m

5. high quality

6. UX Geogrid are extruded in HDPE or PP. It can provide high strength in one direction and are typically used on earth walls and slopes under long term high loading ,and slip repairs. These geogrid carry large tensile loads applied in one direction (along the roll), and their open aperture structure interlocks with natural fill materials.

Virtues of using HDPE Uniaxial Geogrid:

1. Reinforcing roadbed, effectively dispersing and diffusing load, enhancing roads stability and loading ability

2. elongating the engineering lifespan.

3. cutting down the project cost, elongating using life and decreasing the maintenance cost

4. Applied to all kinds of soil

Applications of HDPE Uniaxial Geogrid:

1. Reinforced soil retaining walls

2. Reinforcement of soil structures

3. Construction on difficult foundation soils

4. Reinforced embankment over soft foundation

5. Road base reinforced

6. Steep reinforced slops

7. Installation guide : see website

Property of HDPE Uniaxial Geogrid:

|

Type Item |

TGDG25 |

TGDG35 |

TGDG50 |

TGDG80 |

TGDG110 |

TGDG120 |

TGDG150 | |

|

Width(mm) |

1100 | |||||||

|

Length /roll (m) |

50 | |||||||

|

Yield strength |

HDPE |

25 |

35 |

50 |

80 |

110 |

120 |

150 |

|

≥KN/M |

PP |

25 |

35 |

50 |

80 |

110 |

120 |

150 |

|

Elongation |

HDPE (%) |

11月16日 | ||||||

|

PP≤(%) |

10 | |||||||

|

Strength at 2% elongation ≥KN/M |

HDPE |

6 |

9 |

10 |

23 |

30 |

35 |

46 |

|

PP |

7 |

10 |

12 |

26 |

32 |

38 |

48 | |

|

Strength at 5% elongation ≥KN/M |

HDPE |

12 |

18 |

25 |

44 |

60 |

70 |

87 |

|

PP |

14 |

20 |

28 |

48 |

64 |

75 |

93 | |

|

Price FOB Qingdao USD/sq.m |

HDPE |

0.59 |

0.76 |

1.07 |

1.48 |

1.87 |

2.05 |

2.79 |

|

Load qty Per 40’container sq.m |

HDPE |

28000 |

28000 |

27500 |

20000 |

13000 |

12000 |

|

|

PP |

33000 |

33000 |

32000 |

27500 |

20000 |

15400 |

11550 | |

|

Remarks: The price will be made according to our final confirmation. | ||||||||

Packaging & Delivery of HDPE Uniaxial Geogrid:

Packaging Detail: Standard Export Packing. Or according to customer request

Delivery Detail: within 15 days after receiving the deposit

- Q: Glass fiber grille is not geogrid

- Yes, one of the three categories of geogrid. Fiberglass grille is another kind of glass fiber geogrid.

- Q: Are geogrids resistant to hydrostatic pressure?

- Yes, geogrids are resistant to hydrostatic pressure. They are designed to provide structural support and reinforcement to soil, helping to distribute and reduce the pressure exerted by water or other fluids.

- Q: How are geogrids connected to the surrounding soil?

- Geogrids are connected to the surrounding soil through a mechanism called soil interlocking. The geogrids have open spaces or apertures that allow the soil particles to penetrate and interlock with the geogrid structure. This interlocking creates a strong bond between the geogrid and the soil, providing reinforcement and stability to the soil structure.

- Q: Do geogrids have any impact on groundwater?

- Yes, geogrids typically have no impact on groundwater as they are non-permeable materials used primarily for soil stabilization and reinforcement purposes.

- Q: Classification and application of polyethylene geogrid?

- The utility model is suitable for the construction of roads, railways, rivers, lakes, and coastal areas, such as reinforced retaining walls, dams, bridge decks, steep slopes and geocell. Its function is to improve the bearing capacity of the retaining wall or embankment, prolong the service life, reduce the occupation area, shorten the construction period, reduce the cost and reduce the maintenance cost.

- Q: Do geogrids provide reinforcement to geosynthetic clay liners in landfill caps?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in landfill caps. Geogrids are commonly used to enhance the stability and load-bearing capacity of geosynthetic clay liners by providing additional tensile strength and preventing lateral displacement of the clay liner. This reinforcement helps to improve the overall performance and longevity of landfill caps.

- Q: Can geogrids be used in ground stabilization for oil and gas facilities?

- Yes, geogrids can be used in ground stabilization for oil and gas facilities. Geogrids are highly effective in reinforcing the soil and providing stability, which is essential for supporting heavy equipment and infrastructure in these facilities. They help to prevent soil erosion, increase load-bearing capacity, and improve overall ground stability, making them a suitable solution for oil and gas facilities.

- Q: Is the test items within the inspection listAcceptance specification

- Lower bearing layer smoothness

- Q: Glass fiber grille modified asphalt, polyester grille coated PVC.

- This is the business secret of the production enterprise.

- Q: What are the models and specifications of Geogrid for road

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1987 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Miragrid Gx High Quality HDPE Uniaxial Geogrids

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000m2 m²

- Supply Capability:

- 100 million Square Meter Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords