HDPE Geocells Fiberglass Geogrid with CE Certificate in Low MOQ

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

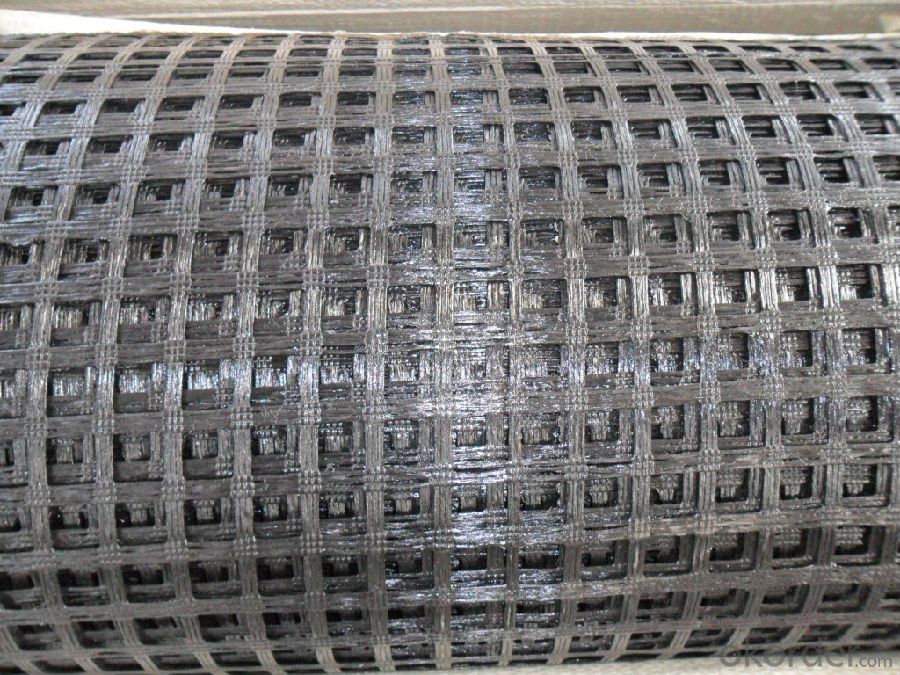

Fiberglass Geogrid with CE Certificate in Low MOQ

Description Of Fiberglass Geogrid with CE Certificate in Low MOQ:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Main Features of Fiberglass Geogrid with CE Certificate in Low MOQ:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid with CE Certificate in Low MOQ:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with CE Certificate in Low MOQ:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1.Suitable for highway, railway, airport road of subgrade enhancement.

2.Suitable for the large parking lot and port freight yard that the foundations of the permanent load increased.

3.Suitable for railway, highway slope protection.

4.Suitable for culverts.

5.Suitable for the uniaxial tensile geogrid reinforced soil secondary enhancement, after further enhance soil, prevent soil erosion.

6.Mining, tunnel reinforcement.

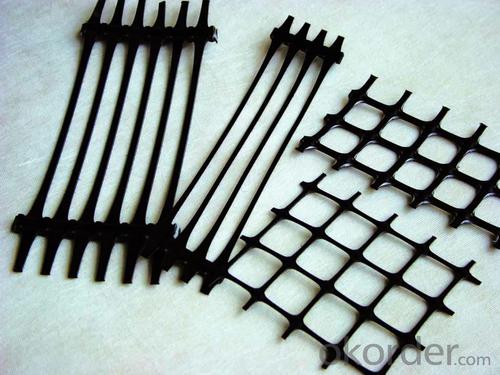

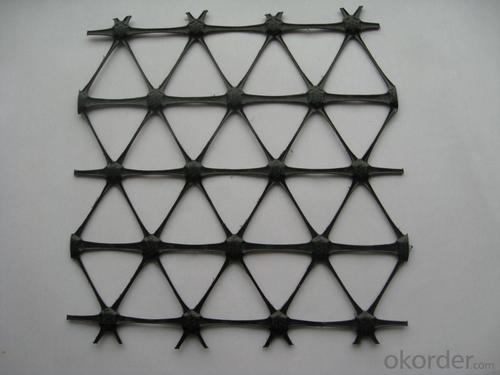

IMages of Fiberglass Geogrid with CE Certificate in Low MOQ:

FAQ of Fiberglass Geogrid with CE Certificate in Low MOQ:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What is the effect of geogrid aperture size on performance?

- The effect of geogrid aperture size on performance is that it directly influences the soil's interlocking capability with the geogrid. Smaller aperture sizes enhance the interlocking mechanism, leading to improved load distribution and higher tensile strength. On the other hand, larger aperture sizes may reduce the interlocking efficiency, potentially compromising the geogrid's overall performance in terms of reinforcement and stabilization.

- Q: Can geogrids be used in mining haul roads?

- Yes, geogrids can be used in mining haul roads. Geogrids are commonly used in construction and infrastructure projects to improve the stability and load-bearing capacity of roads. In mining operations, haul roads are subjected to heavy loads from trucks and equipment. By incorporating geogrids into the road design, they can provide reinforcement and prevent soil or aggregate movement, ultimately increasing the lifespan and durability of the haul roads in mining environments.

- Q: How do geogrids help in soil reinforcement?

- Geogrids help in soil reinforcement by providing a strong and stable framework within the soil, preventing its movement and improving its load-bearing capacity. They act as a tensional element, distributing the applied loads and reducing the stress on the soil. This reinforcement helps in preventing soil erosion, improving slope stability, and enhancing the overall performance and longevity of various civil engineering structures.

- Q: How do geogrids reduce the amount of fill required for construction?

- Geogrids reduce the amount of fill required for construction by providing reinforcement and stability to the soil, allowing for a steeper slope or thinner layer of fill to be used. This is achieved through the interlocking design of the geogrid, which distributes the load more evenly, minimizing settlement and preventing soil movement.

- Q: Can geogrids be used in slope protection systems?

- Yes, geogrids can be used in slope protection systems. Geogrids are commonly used to reinforce slopes by providing stability and preventing soil erosion. They can be installed horizontally or vertically to improve the strength of the soil and enhance the overall performance of slope protection systems.

- Q: How do geogrids enhance the performance of geocell confinement systems?

- Geogrids enhance the performance of geocell confinement systems by providing additional strength and stability. They are placed within the cells of the geocell structure and act as a reinforcement, increasing the load-bearing capacity of the system. This reinforcement helps to distribute the applied loads more evenly, reducing the potential for deformation or collapse of the geocell walls. Additionally, geogrids improve the overall stability of the geocell structure by preventing lateral movement of the fill material and enhancing its confinement, resulting in improved performance and durability of the system.

- Q: Can geogrids be used in floating road construction?

- Yes, geogrids can be used in floating road construction. Geogrids are often used to reinforce and stabilize the subgrade in road construction projects, including floating roads. They provide additional strength and stability to the road structure, allowing it to withstand heavy loads and prevent deformation.

- Q: Can geogrids be used in soil reinforcement for pipeline projects?

- Yes, geogrids can be used in soil reinforcement for pipeline projects. Geogrids are commonly used in civil engineering projects to improve soil stability and prevent soil erosion. They are effective in providing reinforcement and reducing the potential for soil settlement, making them suitable for enhancing the stability of pipelines in various soil conditions.

- Q: What are some common standards and specifications for geogrids?

- Some common standards and specifications for geogrids include the ASTM D6637 standard for uniaxial geogrids, the ASTM D6917 standard for biaxial geogrids, and the ISO 10318 standard for geosynthetics. These standards outline requirements for geogrid properties such as tensile strength, elongation, aperture size, and durability, ensuring quality and consistency in geogrid products.

- Q: Biaxial tension geogrid

- In addition, there are steel plastic grille, fiberglass geogrid and so on

Send your message to us

HDPE Geocells Fiberglass Geogrid with CE Certificate in Low MOQ

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords