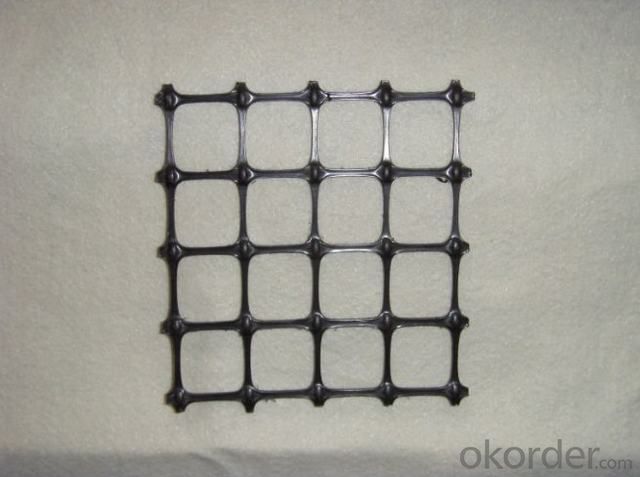

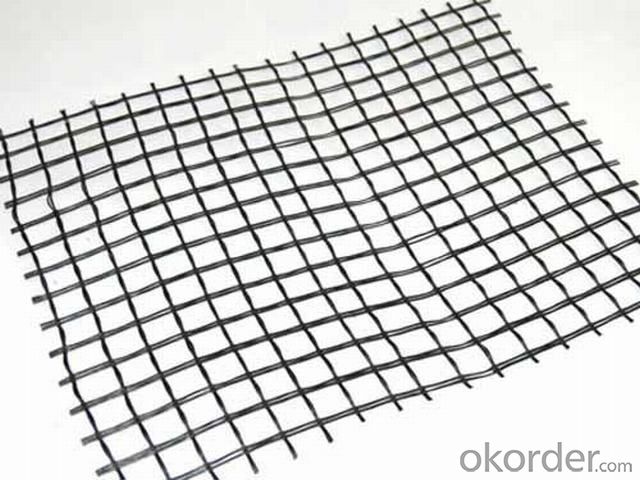

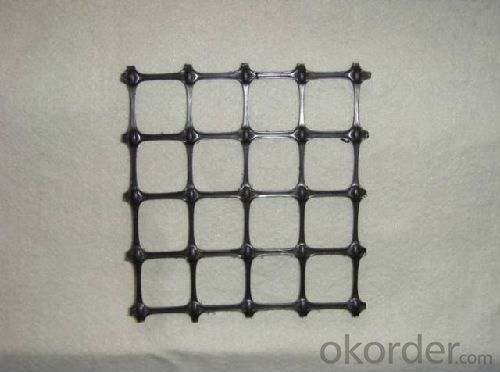

HDPE Uniaxial Geogrid for Retaining Walls and Slops

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Uniaxial Geogrid Product Introduction

High strength polyester warp-knitting geogrid adopts high strength, high modulus, and low shrinkage twisting industrial polyester fiber as raw material. It is warp knitted with oriented structure and in the condition of no bending among warp and weft direction. Its crossing points are bundled and bended together by high strength long polyester fiber forming tough conjunction. Then it forms into mesh size product after coated with high quality water-soluble PVC which improves its strength, shearing force, various technical standards and gives full paly of its mechanical property.

HDPE Uniaxial Geogrid Product Features

1. High strength, high modulus and low elongation.

2. Aging resistance and high tensile strength.

3. Pre-designed and easily combing with gravel and soil.

HDPE Uniaxial Geogrid Product Application

1. Strengthening soft roadbed of high-class roads and high speed railways,

separating different subgrade soil material.

2. Using in reclamation engineering, dam, landslides and retaining wall.

3. Enhancing various roadbeds.

4. Strengthening soft roadbed of airport.

HDPE Uniaxial Geogrid Product Specification

Item | 50 | 80 | 120 | 140 | 160 | 170 | 200 |

Vertical Tensile Strength (KN/m) ≥ | 50 | 80 | 120 | 140 | 160 | 170 | 200 |

elongation ration(%)≤ | 11.5 | ||||||

Tensile Strength at 2% elongation (KN/m) ≥ | 12 | 21 | 33 | 38 | 47 | 49 | 58 |

Tensile Strength at 5% elongation (KN/m) ≥ | 23 | 40 | 65 | 75 | 93 | 98 | 115 |

Length (m) | 50 | ||||||

Width (m) | 1.0/1.1 | ||||||

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway and dam etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: Evaluation criteria and technical disclosure of geogrid.. Know how to share. Thank you

- 2) according to the design of the location, along the road to the laying of the grid, laying the grille, should pay attention to the connection between the grid and straightening smooth. Grille of the longitudinal and transverse joints can use nylon or polyester rope sewn or U nail connection method between the grid as a whole, grid overlapping width not less than 20cm, in the direction of the stress intensity of the joint shall not be less than the design tensile strength of materials. The grid distortion, fold, overlap, is not conducive to play its role, thus laying by hands straightened, the grid is smooth and uniform, geogrid every 1.5-2.0m paved with hook nail fixed on the ground.

- Q: How do geogrids improve the performance of geocomposite drains?

- Geogrids improve the performance of geocomposite drains by providing reinforcement and stability to the drain system. They enhance the load-bearing capacity of the drain, prevent soil movement, and distribute the load more evenly. This helps in increasing the overall strength and longevity of the drain, improving its performance and effectiveness in draining water.

- Q: Polypropylene geogrid

- Hello! ~ ~ ~ the so-called polypropylene is just a kind of material, the material has PP and polyethylene (HDPE) these two kinds

- Q: How do geogrids improve the performance of geosynthetic-reinforced walls?

- Geogrids improve the performance of geosynthetic-reinforced walls by providing additional tensile strength and stability to the structure. They act as a reinforcement material, distributing the load and preventing soil movement or wall failure. Geogrids also enhance the overall durability and longevity of the wall by reducing the potential for settlement, soil erosion, and deformation.

- Q: Can geogrids be used in temporary construction access mats for environmentally sensitive areas?

- Yes, geogrids can be used in temporary construction access mats for environmentally sensitive areas. Geogrids are commonly used in construction projects to provide stabilization and reinforcement to the ground. They are designed to distribute weight and reduce ground pressure, making them suitable for protecting sensitive areas from damage caused by heavy construction equipment or vehicles. Additionally, geogrids are often made from environmentally friendly materials and can be easily removed and reused, minimizing their impact on the environment.

- Q: What is the meaning of the geogrid check bond frequency 2%

- This bond is really not heard, you say is not the kind of sticky,

- Q: Are geogrids easy to install?

- Yes, geogrids are relatively easy to install. They can be installed using simple tools and equipment, and the process generally involves unrolling the geogrid, securing it in place, and covering it with soil or aggregate material. However, the ease of installation can vary depending on the specific project and site conditions.

- Q: Panzhihua steel plastic composite geogrid manufacturers, how much money, where to sell

- But in the actual project, after the packing compaction, therefore has not been subjected to the ultraviolet light and the oxygen erosion, therefore completely may satisfy the permanent construction request.

- Q: The future of geotechnical materials

- steel-plastic composite geogridThe steel plastic geogrid with the high strength steel wire, through the special treatment, and PE, and the addition of other additives, through extrusion to make it into a composite high tensile band, and the surface of the coarse grain, it is high strength reinforced geotextile. The single belt is formed by the longitudinal and horizontal spacing or the clamping arrangement, and the welding joint is formed by adopting the welding technology of special strengthening bonding to weld the joint.

- Q: Glass fiber mesh cloth is mainly used in what place

- Wall materials (such as glass fiber wall cloth, GRC wall panels, EPS internal and external wall insulation board, gypsum board, etc.)

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

HDPE Uniaxial Geogrid for Retaining Walls and Slops

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords