Geogrids and Soil Stabilisation Materials - HDPE Uniaxial Geogrid for Embankments High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Uniaxial Geogrid Products Profile

HDPE uniaxial geogrid is manufactured by a process of extruding, punching, heating and longitudinal stretching. It is made of high density polyethylene and they are chemically inert, unaffected by the U.V. rays and fully resistant to aging in the soil environment. it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

HDPE Uniaxial Geogrid Products Features

High strength

High modulus

Low temperature resistance

Very convenience in construction

Very competitve price

HDPE uniaxial geogrid Application Range:

Make reinforcement for various kinds of soft foundation enhance and improve bearing ability of the roadbed, make reinforcement for retaining wall, steep slope, dam and bridge abutment unders stress status for long term thus to improve quality and prolong service life of the project.

1,It is mainly used in retaining wall, bridge abutment, steep slope project and so on.

2,Retaining wall and bridge abutment belong to force bearing structures and bear all external loads such as active soil pressure, support of structure upper part and temperature stress, under the function of large tension and repeated function of dynamic load ,molecule structure of reinforcement material occurs fatigue, its performance occurs attenuation and aging of grid quickens. In order to avoid large deformation of structure caused by creep of reinforcement material, unidirectional geotechnical grid with high-density polyethlene(HDPE) as raw material shall be used.

HDPE uniaxial geogrid specifications

Specs | Tensile strength (kN/m) | Tensile strength at 2% strain (kN/m) | Tensile strength at 5% strain (kN/m) | Elongation /% |

35 | ≥35.0 | ≥7.5 | ≥21.5 | ≤11.5 |

50 | ≥50.0 | ≥12.0 | ≥23.0 | |

80 | ≥80.0 | ≥21.0 | ≥40.0 | |

120 | ≥120.0 | ≥33.0 | ≥65.0 | |

160 | ≥160.0 | ≥47.0 | ≥93.0 |

FAQ

1. What's the usage of Polypropylene Biaxial geogrid?

It's used for reinforce the roadbeds in softe soil, railway, tunnel, slope and embankment etc. It has good performance on preventing the cracks.

2. How about your quality of Polypropylene Biaxial geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

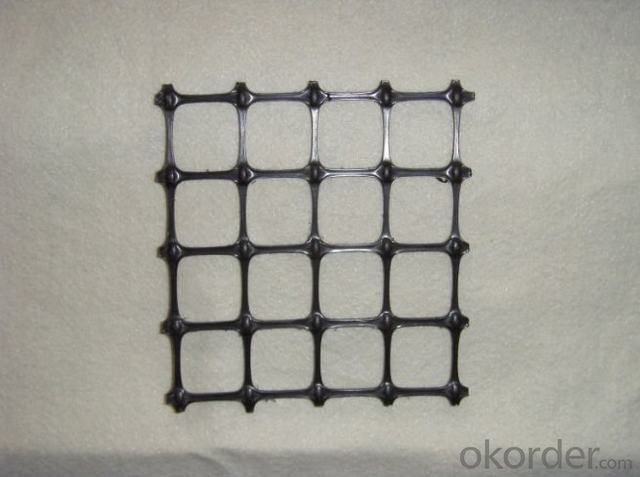

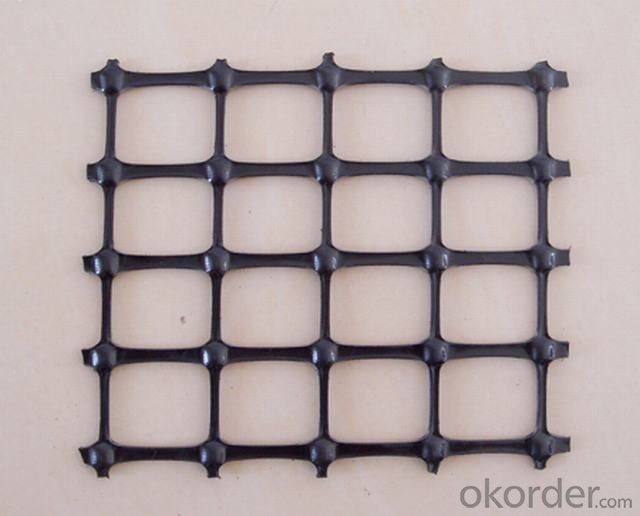

HDPE uniaxial geogrid photos

- Q: Can geogrids be used in temporary construction access mats?

- Yes, geogrids can be used in temporary construction access mats. Geogrids are commonly used to improve the stability and load-bearing capacity of access mats, making them suitable for temporary construction sites. They help distribute the weight of heavy equipment and vehicles and prevent soil erosion, ensuring safe and efficient access for construction activities.

- Q: How much is the tensile strength of Geogrid

- Solder paste type: 200KN or less.

- Q: The difference between two way steel plastic grille and one way steel plastic grille

- There difference

- Q: Can geogrids be used for load distribution?

- Yes, geogrids can be used for load distribution. Geogrids are specifically designed to distribute loads over a wider area, improving the stability and strength of various structures such as roads, retaining walls, and embankments. They help to spread the applied load more evenly, reducing the potential for localized stress and preventing the formation of cracks or failures.

- Q: Do geogrids provide reinforcement to geosynthetic clay liners in landfill caps?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in landfill caps. Geogrids are commonly used to enhance the stability and load-bearing capacity of geosynthetic clay liners by providing additional tensile strength and preventing lateral displacement of the clay liner. This reinforcement helps to improve the overall performance and longevity of landfill caps.

- Q: How do geogrids help in reducing soil settlement?

- Geogrids help in reducing soil settlement by providing reinforcement to the soil structure, which helps distribute the load more evenly and prevent excessive settlement. They act as a stabilizing element by increasing the tensile strength of the soil, preventing its movement and settling.

- Q: How do geogrids improve the stability of landfills?

- Geogrids improve the stability of landfills by providing reinforcement and preventing soil movement. They distribute loads more evenly, reduce the potential for slope failure, and increase the overall strength of the landfill structure.

- Q: What is the effect of creep on geogrid performance?

- The effect of creep on geogrid performance is that it can cause long-term deformation and reduced tensile strength over time. Creep refers to the gradual movement or deformation of a material under constant load or stress. In the case of geogrids, prolonged exposure to sustained load or stress can result in creep, leading to a loss of the geogrid's initial stiffness and load-bearing capacity. This can negatively impact its ability to provide soil reinforcement, stability, and confinement, compromising its overall performance in geotechnical applications. Therefore, creep considerations are crucial when designing and selecting geogrids for long-term projects.

- Q: What is the effect of installation damage on geogrid performance?

- Installation damage can have a significant impact on geogrid performance. When geogrids are improperly installed or handled, they can sustain damage such as tears, punctures, or stretching. These damages can weaken the geogrid's structural integrity and compromise its ability to provide reinforcement and stabilization in soil or aggregate applications. As a result, the geogrid may not be able to withstand the intended loads and stresses, leading to reduced performance and potential failure of the geosynthetic system. Therefore, proper installation techniques and careful handling are crucial to ensure optimal geogrid performance and longevity.

- Q: What are the factors to consider when selecting a geogrid for a specific application?

- When selecting a geogrid for a specific application, several factors need to be considered. These include the desired strength and stiffness of the geogrid, the anticipated load and traffic conditions, the soil type and properties, the environmental and climate conditions, the installation and construction methods, and the project budget. Additionally, the compatibility of the geogrid with other materials and its long-term durability should also be taken into account. Ultimately, the geogrid chosen should be able to effectively reinforce and stabilize the soil, withstand the expected loads, and provide optimal performance for the specific application.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Geogrids and Soil Stabilisation Materials - HDPE Uniaxial Geogrid for Embankments High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords