HDPE Geocells PP Biaxial Geogrid with High Tensile Strength Direct Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

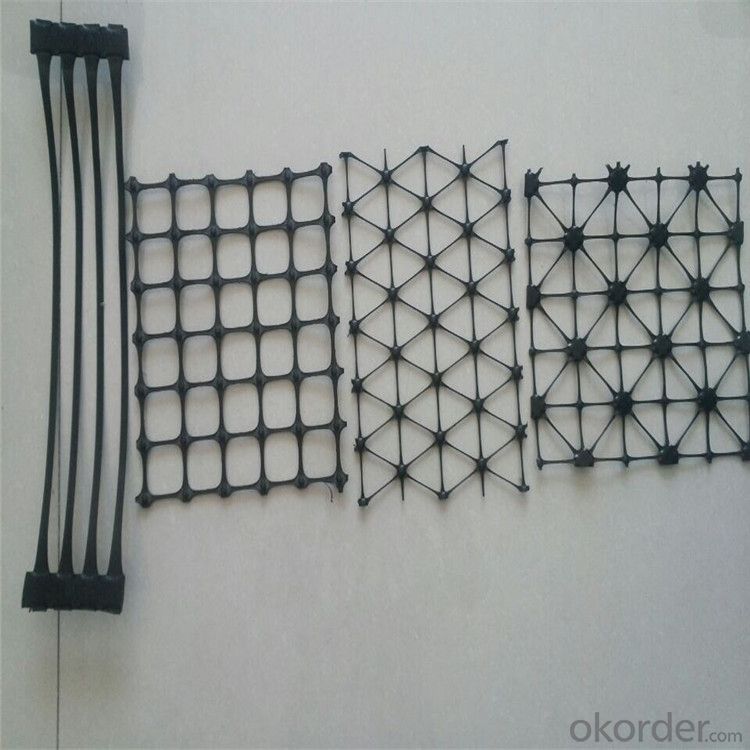

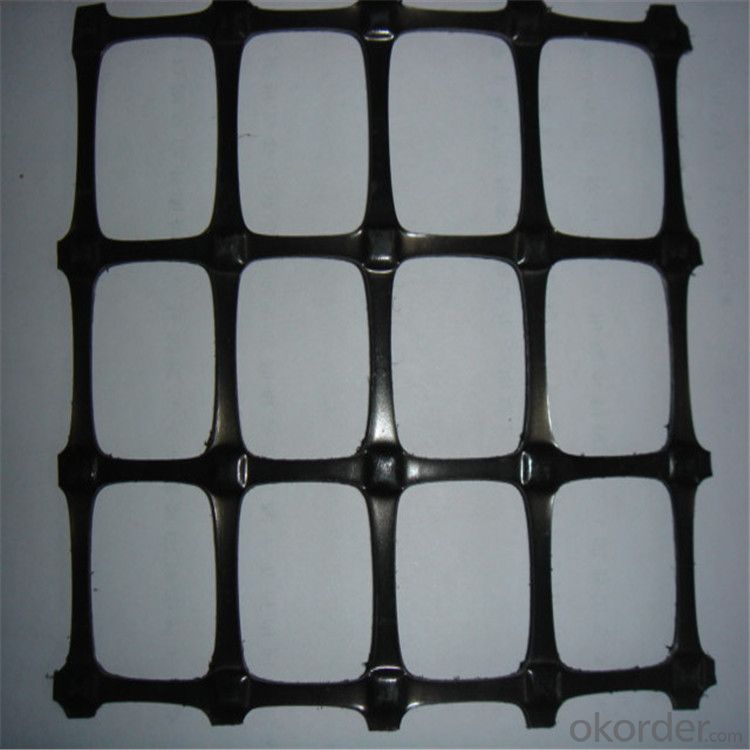

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Properties of PP Biaxial Geogrid

Item Spec | TGSG 15-15 | TGSG 20-20 | TGSG 25-25 | TGSG 30-30 | TGSG 35-35 | TGSG 40-40 | TGSG 45-45 | TGSG 50-50 | ||

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

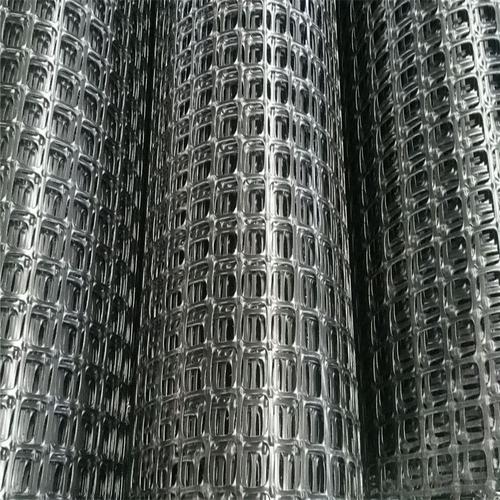

Images of PP Biaxial Geogrid

- Q: Can geogrids be used in temporary soil stabilization applications?

- Yes, geogrids can certainly be used in temporary soil stabilization applications. Geogrids are commonly employed in various civil engineering projects to reinforce and stabilize soil. They provide temporary support and enhance the strength of the soil, preventing erosion and maintaining stability during construction or other temporary applications.

- Q: Can geogrids be used in water drainage applications?

- Yes, geogrids can be used in water drainage applications. Geogrids are commonly used in civil engineering projects to improve soil stability and reinforce the ground. They can be installed in various types of water drainage systems, such as retaining walls, embankments, and underground drainage pipes, to enhance their overall performance and prevent soil erosion.

- Q: Can geogrids be used in stabilization of riverbanks?

- Yes, geogrids can be used in the stabilization of riverbanks. Geogrids are commonly utilized in civil engineering and geotechnical applications to reinforce soil and prevent erosion. By providing additional strength and stability to the riverbank, geogrids help to prevent soil erosion, reduce sedimentation, and protect against damage caused by water flow, ultimately enhancing the stability and longevity of the riverbank.

- Q: Peel force mainly in the size of raw materials

- Depends on the strength of the welding point

- Q: What are the benefits of using geogrids in roadways?

- The benefits of using geogrids in roadways are numerous. Firstly, geogrids provide reinforcement to the road surface, increasing its strength and stability. This helps in preventing the formation of cracks and potholes, leading to longer-lasting and more durable roads. Secondly, geogrids help in distributing the load from vehicular traffic more evenly, reducing the stress on the road and preventing premature deterioration. Additionally, geogrids improve the overall performance of the road by enhancing its resistance to rutting, erosion, and other forms of pavement distress. Moreover, geogrids can reduce construction costs by reducing the amount of aggregate required for road construction. Overall, the use of geogrids in roadways improves their longevity, reduces maintenance needs, and enhances the safety and comfort of road users.

- Q: Can geogrids be used in slope stabilization for mining waste dumps?

- Yes, geogrids can be used in slope stabilization for mining waste dumps. Geogrids are high-strength materials that provide reinforcement and stability to slopes, preventing erosion, soil movement, and potential slope failure. By installing geogrids in mining waste dumps, the slopes can be reinforced, reducing the risk of landslides and ensuring the safety and stability of the dump.

- Q: Can geogrids be used in reinforcement of soft soils?

- Yes, geogrids can be used in the reinforcement of soft soils. Geogrids are commonly employed in geotechnical engineering to enhance the stability and strength of weak or soft soils. They provide tensile reinforcement to the soil, improving its load-bearing capacity, reducing settlement, and preventing soil erosion. Geogrids work by distributing and transferring applied loads more efficiently, thereby mitigating the potential for soil failure.

- Q: The difference between geocell and geogrid

- Main use1, used to stabilize the road, railway roadbed.2, used to withstand the gravity of the embankment and shallow water channel.3, for the prevention of landslides and the load of gravity mixed retaining wall.4, in the face of soft ground. The use of geocell can greatly reduce the construction labor intensity, reduce the thickness of roadbed construction speed, good performance, greatly reduce the cost of the project.A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: Can geogrids be used in bridge abutments?

- Yes, geogrids can be used in bridge abutments. Geogrids are commonly used in soil stabilization and reinforcement applications, and they can be effectively used to improve the stability and strength of bridge abutments. By installing geogrids in the soil surrounding the abutments, the geogrids can distribute loads more evenly, prevent soil erosion, and provide additional support to the bridge structure.

- Q: Are geogrids resistant to chemical degradation?

- Yes, geogrids are generally resistant to chemical degradation. They are designed to withstand exposure to various chemicals, including acids, alkalis, and hydrocarbons, without significant deterioration or loss of strength. However, the specific resistance may vary depending on the type of geogrid and the specific chemicals involved.

Send your message to us

HDPE Geocells PP Biaxial Geogrid with High Tensile Strength Direct Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords