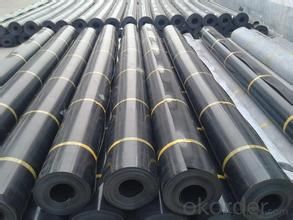

High Density Polyethylene(HDPE) Geomembrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of HDPE Geomembrane Description:

HDPE geomembrane is choosed high quality polyethylene native resin, main ingredients for 97.5% of the high density polyethylene, about 2.5 # carbon black, anti-aging agent, antioxidant and uv absorber, stabilizer, accessories, with currently the most advanced fully automatic geotechnical Italian production equipment, through three layers co-extrusion technology. All products are according to the GRI standards and ASTM testing standards production, complete specifications, smooth rough thickness 0.20 mm to 0.20 mm, 6 m and 12 m wide, the product is not hygroscopic and has a good waterproof steam.

2.Main Features of HDPE Geomembrane:

Low density, good tightness

Excellent chemical stability, high and low temperature resistance, resistance to asphalt.

Good anti-aging, anti-uv resistance.

Excellent puncture resistance

3.HDPE Geomembrane Specification:

| Density(g/cm3) | 0.75 | 1.00 | 1.5 | 2.0 |

The yield strength(N/mm) | 11 | 15 | 22 | 29 |

| Elongation at break(%) | 700 | |||

Puncture strength N | 240 | 320 | 480 | 640 |

Rectangular tear strength | 93 | 125 | 187 | 311 |

4.HDPE Geomembrane Images:

- Q: Bathroom first leveling or do waterproof, what is the difference

- 5. backfill rough flat mortar leveling, and its slope and do waterproof with the grassroots level and grass-roots waterproof, not tired. But pay special attention to this layer of closed water test (for most of the lack of toilet in the ground) is more important. 6. The surface layer and the adhesive layer, requires the slope has been done to slope or squatting, wall tiles to cover the tiles, reduce water into the wall.

- Q: Slope roof drains do not need to be waterproof

- need. Roof waterproof layer regardless of which form and materials, constitute the entire roof of the waterproof drainage system, all the necessary pipes, flues, drainage holes, embedded iron and pillars and other roof out of the facilities, should be done in the roof waterproof Layer to properly handle the structure of the node, with particular attention to the connection part of the soil and the drain part of the water flow.

- Q: How to do waterproof bathroom, construction process is what

- 3, shop protective layer. In order to prevent the subsequent construction damage to the waterproof layer, the need to cover the surface of the waterproof coating protective layer. Protective layer to completely cover the waterproof layer, no missing, with the grass-roots combination of solid, no cracks, no bubbles, no shedding phenomenon.

- Q: Cabinet is to buy finished products, or directly to the decoration company to do?

- Do the cabinet can be in accordance with your size, finished cabinet moldy, which is not necessarily. You have to buy some of the Well

- Q: Roof membrane waterproof construction process, what should be noted that?

- Four do not: 1 surface can not afford sand 2 surface can not afford skin 3 surface is not crisp 4 does not crack

- Q: Home improvement waterproofing problem

- 1, you said the above three products are old products. It is recommended to use the latest dosage form of cf-2000 efficient composite waterproofing agent, is the latest cement-based crystalline products. Not only then to solve the leakage problem, and the composite waterproof agent in the active material in the water or moisture under the action, but also continue to penetrate into the concrete layer. The formation of 10 cm from the self-waterproof layer. If the self-waterproof layer due to external factors caused by small cracking, as long as there is water through, you can start the active substance of the secondary repair function, to automatically repair the crack water seepage.

- Q: Nanning building waterproof material market where

- to buy what materials are going to go to some factories, such as paper, printing materials and other manufacturers in the Nanning High-tech Zone or Nanning Economic Development Zone may be more

- Q: How can the toilet waterproof works fail?

- Can only do a new waterproof, and now have engaged in the base of the waterproof coating, the effect is very good. It is best to ask professionals to do their own difficult.

- Q: How does the waterproofing membrane work?

- 3, the ignition: first open the liquefied gas cylinder switch, and then hand gun slowly open the gun switch, to be heard when the gas hissing sound, ignite the flame, and then adjust the switch, the flame was blue. Ignite people should stand behind the nozzle side, so as not to be burned by fire;

- Q: Waterproof material water leakage construction should pay attention to what

- Or to local, if it is a bathroom, it should pay attention to these points: Bathroom waterproof practice: 1, ground handling Before the water treatment, must first find the ground. Leveling layer of construction methods: the base surface with gaps, cracks, unequal defects, with cement mortar repair smooth. So that the base surface must be strong, smooth, clean, dust-free, greasy, wax, release agent, and other debris material. Leveling layer before drying can be waterproof construction, construction should be fire, waterproof. After the completion of the waterproof layer, to be finished product protection, not on the move.

Send your message to us

High Density Polyethylene(HDPE) Geomembrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords