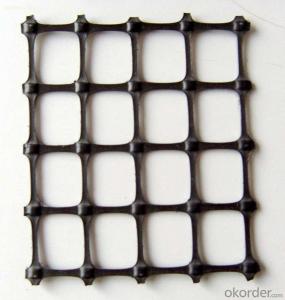

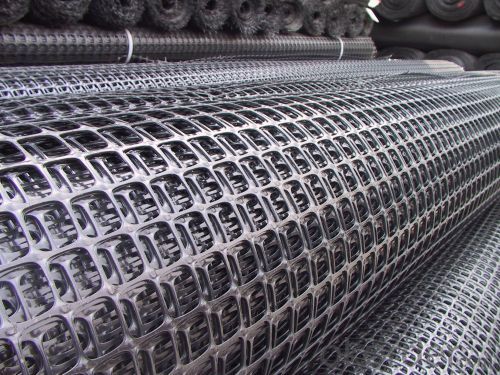

HDPE Geocells PP Plastic Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial PP Geogrid,

Biaxial geogrids are made of macromolecule polymer by the process of being stretched out, formed into lamella, punched regularly and then longitudinal and transverse elongated. They have much higher longitudinal and transverse tensile strength. These structures can supply alinking system to soil, which be used broadly to enable the permanent bearing capacity of roadbed.

Biaxial Geogrid Features:

1. high tension resistance.

2. high plane torsion resistance modulus.

3. good creep resistance and stable chemical nature.

4. high mechanic damage resistance.

5. reduce filling thickness, improve bearing capacity.

The main function as follows:

1.Reinforce the base, efficiently allot and diffuse the pressure, prolong the using time;

2.Increase the load-bearing capabilities;

3.Avoid the base becoming deformed and creaking (for the material washed away);

4.Improve the endure, reduce the pressure of the blocking wall, save the cost, prolong the using time, and reduce the servicing;

5.Reduce the crook and track, delay 3-9 times of the appearance of the crack, reduce 36% of the thickness of the structure by adding the geogrid into the base and cover of the road,

6.Be applicable of all kinds of soil;

7.Be easy to construct and reduce the cost.

Geogrid Features:

(1)High intension,high tenacity,high occlusive force with soil or gravel,erosion-resistant,

water drainage,light weigth.

(2)Reinforce soft soil roadbed,rib side slope of embankment,enhance isolation,

inhibit ground deformation,prevent crack by reflection,increase strength of roadbed.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: What are the potential drawbacks of using geogrids?

- One potential drawback of using geogrids is the high cost associated with their installation and maintenance. Geogrids are typically made from synthetic materials, which can be expensive to produce and purchase. Additionally, the installation process often requires specialized equipment and skilled labor, further increasing the overall cost. Another drawback is the limited effectiveness of geogrids in certain soil conditions. Geogrids are typically designed to enhance soil stability and reinforce weak or unstable soils. However, in cohesive soils or highly organic soils, geogrids may not provide the desired level of reinforcement. In such cases, alternative solutions or additional measures might be necessary. Moreover, geogrids require proper design and careful installation to ensure their effectiveness. If not installed correctly, geogrids may not perform as intended and could potentially fail. This could result in the need for costly repairs or replacements. Lastly, geogrids may have environmental concerns associated with their production and disposal. Synthetic materials used in geogrids are not biodegradable and may contribute to pollution if not properly managed. Additionally, the manufacturing process of these materials often involves the use of fossil fuels and can generate greenhouse gas emissions. Overall, while geogrids offer numerous benefits in terms of soil reinforcement and stabilization, it is important to consider their drawbacks, including high cost, limited effectiveness in certain soil conditions, installation requirements, and potential environmental impacts.

- Q: How to connect the geogrid with the panel in the reinforced earth retaining wall?

- When the geogrid is laid in the curve and the corner, the adjacent earthwork grid is currently used in the reinforced earth retaining wall of the assembled panel, and the common wall of the assembled panel module will have gaps or overlaps (see Figure 1). For the outward bending of the geogrid, there are different forms such as rectangle, hexagon, shape, L shape and groove shape. Panel module will appear at the corner of the gap,In order to ensure the continuity of the reinforced soil, laying in the void design based on the engineering environment need to be flexible, prefabricated into various shapes, can provide the same type of geogrid small pieces of good, and cover all the reinforced area; for bend shop visual effect; can also use color cement, add art wall. No panel reinforcement design of geogrid, in the corner there will be some overlap in geogrid, geogrid reinforced earth retaining wall is also called anti package type or wrap-reinforcedearth retaining wall, the wall is made of mesh bags to fill the overlap coefficient of friction will be reduced, must be laying a layer of 10mm ~ 20mm thick the soil geogrid anti package into each layer of geogrid is a special connecting rod is connected with the shape of the coarse sand layer, separate the two layer of Geogrid to ensure friction resistance. As a whole, the mesh bag filling has been mixed for local growth of grass and shrub seeds, seeds, after months of growth after the formation of green ecological wall. The utility model not only protects the safety of the geogrid, but also beautifies the environment of the retaining wall project.

- Q: What does the geotextile 200# mean?

- Is 200g/ square meters of geotextiles? The geotextile is generally divided according to the specifications of the weight per unit area. Geotextiles manufacturers Zhang Mingchao answer for you, and I hope to help you.

- Q: Who knows how much the staggered distance of the lap joint of the geogrid is?

- Straight and smooth and close to the cushion, all longitudinal or transverse lap joints should be staggered, overlapping length shall not be less than 300MM.

- Q: How are geogrids used in road construction?

- Geogrids are used in road construction to improve the stability and strength of the road. They are placed between different layers of the road, such as the subgrade and the base course, to distribute the load and prevent the movement of soil particles. This helps to increase the road's durability, reduce deformation, and enhance its overall performance.

- Q: Can geogrids be used in reinforcement of bridge abutments and wing walls?

- Yes, geogrids can be used in the reinforcement of bridge abutments and wing walls. Geogrids are commonly used in civil engineering projects to provide stability and increase the load-bearing capacity of soil. By placing geogrids in the backfill soil behind bridge abutments and wing walls, they can help distribute the loads and prevent soil erosion. This reinforcement technique improves the overall structural integrity of the bridge and enhances its long-term performance.

- Q: Geogrid tgsg50-50 what does it mean

- It is a kind of geogrid with biaxial stretching square mesh. 45-45 is tensile strength

- Q: How do geogrids help in reducing construction equipment requirements?

- Geogrids help in reducing construction equipment requirements by providing reinforcement and stability to the soil. This means that less heavy machinery is needed to compact and stabilize the ground, resulting in cost savings and more efficient construction processes. Geogrids distribute the load evenly, prevent soil erosion, and improve soil bearing capacity, reducing the need for extensive excavation and grading work.

- Q: Are geogrids resistant to chemical exposure?

- Yes, geogrids are typically resistant to chemical exposure. They are designed to withstand various environmental conditions, including exposure to chemicals, without significant degradation or loss of strength.

- Q: Can geogrids be used in erosion control applications on steep slopes?

- Yes, geogrids can be used in erosion control applications on steep slopes. Geogrids are often used to reinforce soil and prevent erosion by providing stability and support to the slope. They can effectively distribute loads and reduce the risk of slope failure, making them suitable for erosion control on steep slopes.

Send your message to us

HDPE Geocells PP Plastic Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords