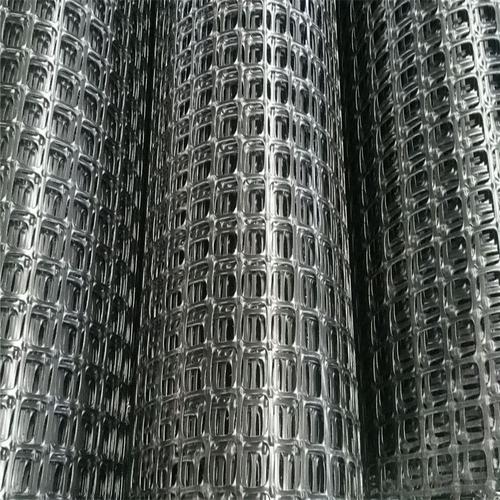

Geogrids Husker HDPE Uniaxial Geogrid with High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification---HDPE UniaxialGeogrid

Introduction:

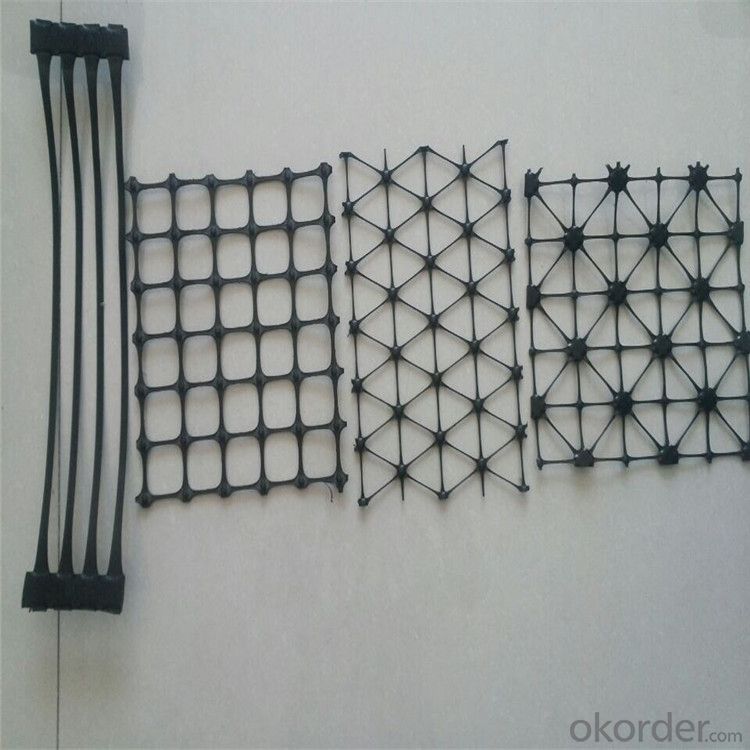

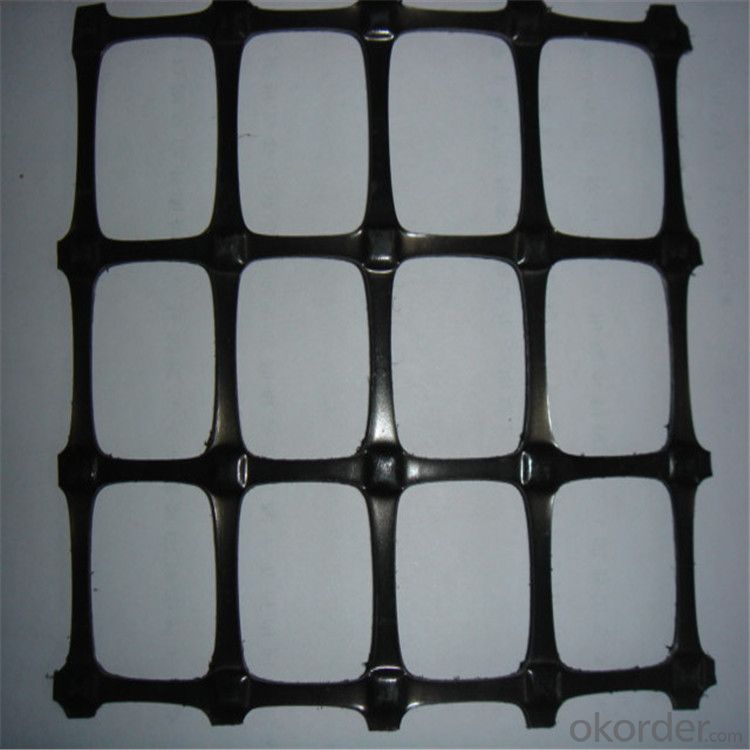

HDPE Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched

into regular mesh pattern, and finally stretched in the longitudinal direction.

Features:

With high tensile strength and tensile modulus

Application:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1) strengthen land loading capacity

and extend its service life.

2) convenient to construct ;

reducing area , project cost and maintenance cost.

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

Images of HDPE Biaxial Geogrid

- Q: How are geogrids installed?

- Geogrids are commonly installed by first excavating the area where they will be placed, then preparing a level and compacted subgrade. The geogrid is then unrolled and laid flat on the subgrade, ensuring it is properly aligned. It is then secured in place by anchoring it with stakes or pins. Finally, the geogrid is covered with the desired fill material, such as soil or aggregate, and compacted to create a stable and reinforced structure.

- Q: What are the advantages of using geogrids in soil nailing applications?

- The advantages of using geogrids in soil nailing applications include increased stability and strength of the soil, reduced erosion and soil displacement, improved load distribution, and enhanced resistance against lateral forces. Geogrids act as reinforcements, acting as a tension element to prevent soil movement and improve overall structural integrity. Additionally, geogrids are cost-effective, easy to install, and can be used in a variety of soil conditions, making them a versatile solution for soil nailing applications.

- Q: How do geogrids improve the stability of levees?

- Geogrids improve the stability of levees by providing reinforcement and increased tensile strength to the soil. These grid-like structures are placed within the levee's soil layers, creating a stable and cohesive system. The geogrids distribute the applied loads more evenly and prevent soil erosion, enhancing the overall stability and strength of the levee structure.

- Q: Geotextiles for geotextiles - Specification for geotextiles

- At the same time has the ability to adapt to the deformation of good, and has good drainage capacity of plane surface, soft multi gap has good friction coefficient can increase soil particle adhesion ability, can prevent the fine particles by preventing particulate loss and eliminate excess water, the surface is soft protection ability good. According to the length of filament is divided into filament non-woven geotextile or short silk non-woven geotextile. They can play a very good filtering, isolation, reinforcement, protection and other functions, is a widely used geosynthetics. The tensile strength of the filament is higher than that of the short filament. Mainly is the high quality polyester staple fiber (fiber based 4-9dtex, length 50-76mm) can also according to the requirements of production of polypropylene, nylon, vinylon fiber or mixed needle nonwoven geotextile. It features 1 isolation of 2 filtered 3 drain 4 reinforcement

- Q: Can geogrids be used in mining haul roads?

- Yes, geogrids can be used in mining haul roads. Geogrids are commonly used in mining haul roads to provide reinforcement and stabilization to the road structure, especially in areas with poor soil conditions or heavy traffic. Geogrids help to distribute the load more evenly, prevent soil erosion, and increase the overall strength and durability of the road, making them a valuable solution for mining haul roads.

- Q: What are the factors affecting the design of geogrid-reinforced structures?

- The factors affecting the design of geogrid-reinforced structures include the type and properties of the soil, the load and magnitude of the forces acting on the structure, the desired level of stability and performance, the site conditions and constraints, and the specific design standards and guidelines applicable to the project.

- Q: Can geogrids be used in slope stabilization for railway embankments in permafrost regions?

- Yes, geogrids can be used in slope stabilization for railway embankments in permafrost regions. Geogrids provide reinforcement and stabilization to the soil, reducing the risk of slope failure and ensuring the stability of the embankment. They are particularly effective in permafrost regions where the frozen ground can be prone to thawing and subsidence. Geogrids improve the overall strength of the embankment, minimize soil movement, and help to maintain the integrity of the railway infrastructure in these challenging environments.

- Q: What is the difference between polyethylene geogrid and uni directional high strength geogrid

- The utility model has the advantages of convenient operation, time saving, labor saving, short construction period and reduced maintenance cost. FourThe utility model relates to a bidirectional grid which is suitable for preventing cracks in culvert. FiveTwo way grid is used to enhance soil slope and prevent soil erosion. Six

- Q: Can geogrids be used in reinforced earth bridge abutments in liquefaction-prone areas?

- Yes, geogrids can be used in reinforced earth bridge abutments in liquefaction-prone areas. Geogrids are commonly used as reinforcement materials in geotechnical engineering to improve the stability and strength of soil structures. In liquefaction-prone areas, where the soil becomes unstable and loses its strength during seismic events, geogrids can provide additional support and prevent potential failures in bridge abutments. By reinforcing the soil, geogrids help to distribute and resist the lateral forces caused by liquefaction, ensuring the stability and safety of the bridge abutments in these vulnerable areas.

- Q: How do geogrids withstand environmental factors such as UV radiation?

- Geogrids are designed to withstand environmental factors such as UV radiation through the incorporation of additives and coatings in their manufacturing process. These additives and coatings help to protect the geogrids from the harmful effects of UV radiation, preventing degradation and ensuring their long-term performance in various applications.

Send your message to us

Geogrids Husker HDPE Uniaxial Geogrid with High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords