Triax HDPE Geogrids for Construction Materials

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

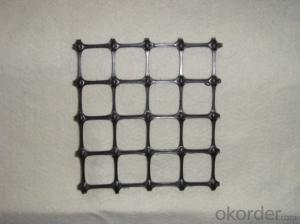

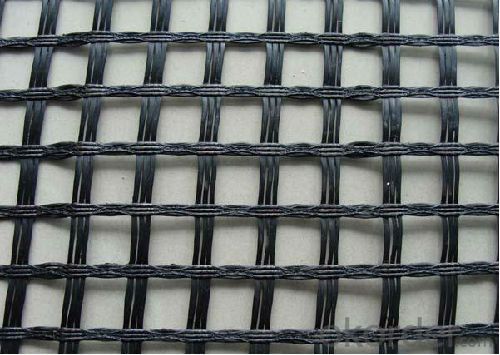

Double-direction geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

2. Product Characteristic:

1. Enhance earth slope and prevent water loss and soil erosion.

2. Convenient construction saves time and labor, reduce mounting time and

3. Increase the bearing capacity of the roadbed and foundation and prolong their service life.

3.Specification:

1. Tensile strength: 15~100KN/M.

2. Color: black etc.

3.Material: PP/PE.

4. Certificate: CE/ISO9001, 14001

Typical Dimensions mm | ||||||

KN | 2020LKN | KN | 3030LKN | KN | 4040LKN | |

Pmd | 40 | 65 | 40 | 60 | 33 | 54 |

Wmd | 2.0 | 3.3 | 2.2 | 3.3 | 2.3 | 3.5 |

Wld | 2.4 | 4.0 | 2.7 | 4.0 | 2.6 | 4.5 |

Tj | 4.1 | 4.3 | 4.3 | 6.5 | 5.5 | 7.5 |

4. Reference Picture:

- Q: What are the long-term performance monitoring requirements for geogrids?

- The long-term performance monitoring requirements for geogrids include regular inspections, assessment of durability and strength retention, measurement of creep and relaxation behavior, evaluation of long-term deformation and stability, and monitoring of the geogrid-soil interaction. Additionally, it is vital to monitor any potential degradation from environmental factors such as UV exposure, chemical exposure, and biological activity to ensure the geogrid's effectiveness over time.

- Q: What kind of circumstances need to shop geogrid

- In the treatment of bad foundation, or the transformation of the old road, geogrid can quickly improve the bearing capacity of the foundation, speed up the progress of construction; control of soft ground settlement development, shorten the construction period, so that the early use of the road.

- Q: Are geogrids suitable for use in agricultural applications?

- Yes, geogrids are suitable for use in agricultural applications. Geogrids have proven to be effective in providing soil reinforcement, erosion control, and stabilization in various agricultural practices such as retaining walls, slope stabilization, and road construction. They can help enhance soil structure, prevent soil erosion, and improve overall stability in agricultural fields.

- Q: Can geogrids be used in slope stabilization for railway embankments?

- Yes, geogrids can be used in slope stabilization for railway embankments. Geogrids are commonly used in civil engineering projects to reinforce soil and provide stability to slopes. By installing geogrids, the embankment's resistance to erosion, sliding, and settlement can be significantly enhanced, making them suitable for slope stabilization in railway applications.

- Q: What are the environmental impacts of using geogrids?

- The environmental impacts of using geogrids can vary depending on factors such as their production, installation, and disposal. However, in general, geogrids can have positive environmental impacts. They can help stabilize soil and reduce erosion, which can prevent the loss of topsoil and decrease sedimentation in nearby bodies of water. Geogrids can also be made from recycled materials, reducing the demand for virgin resources. However, the use of geogrids may also have some negative impacts, such as the energy consumption and greenhouse gas emissions associated with their production and transportation. Additionally, if not properly disposed of, geogrids can contribute to plastic pollution. Overall, while geogrids offer numerous environmental benefits, it is important to consider their life cycle and proper disposal to minimize potential negative impacts.

- Q: What is the difference between Geogrid TGSG and GSL?

- There is a slight difference in the individual indicators, is a product

- Q: Are geogrids resistant to chemical attack?

- Yes, geogrids are generally resistant to chemical attack. They are typically made from high-density polyethylene (HDPE) or other durable materials that can withstand exposure to various chemicals without significant degradation. However, the specific resistance to chemicals may vary depending on the type of geogrid and the specific chemicals involved. It is always advisable to consult the manufacturer's specifications and guidelines to ensure compatibility with specific chemical environments.

- Q: Can geogrids be used in ground stabilization for wastewater treatment plants?

- Yes, geogrids can be used in ground stabilization for wastewater treatment plants. Geogrids are often used in such applications to reinforce and stabilize the soil, preventing erosion and ensuring long-term stability of the facility's infrastructure. They provide additional support to the ground, reducing the risk of settling and maintaining the integrity of the wastewater treatment plant's structures.

- Q: Can geogrids be used in reinforcement of underground parking structures?

- Yes, geogrids can be used in the reinforcement of underground parking structures. Geogrids provide strength and stability to the soil, increasing the load-bearing capacity and preventing soil movement. This makes them an effective solution for reinforcing the ground in underground parking structures, ensuring their durability and structural integrity.

- Q: Glass fiber mesh cloth is mainly used in what place

- Wall materials (such as glass fiber wall cloth, GRC wall panels, EPS internal and external wall insulation board, gypsum board, etc.)

Send your message to us

Triax HDPE Geogrids for Construction Materials

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords