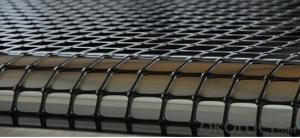

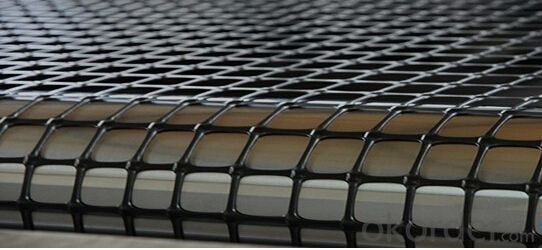

Geocells Philippines - Black Poly HDPE Geogrid and PP Biaxial Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction of Plastic Geogrid

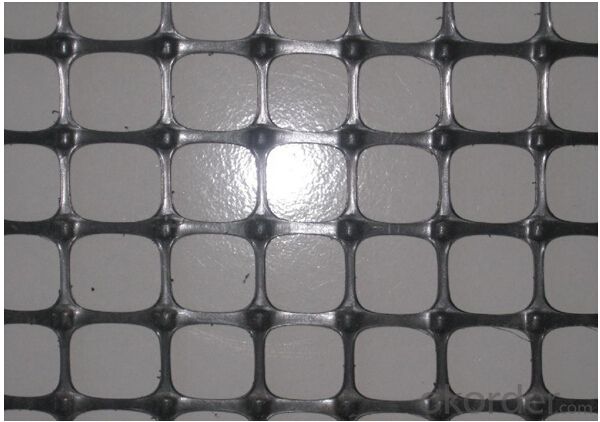

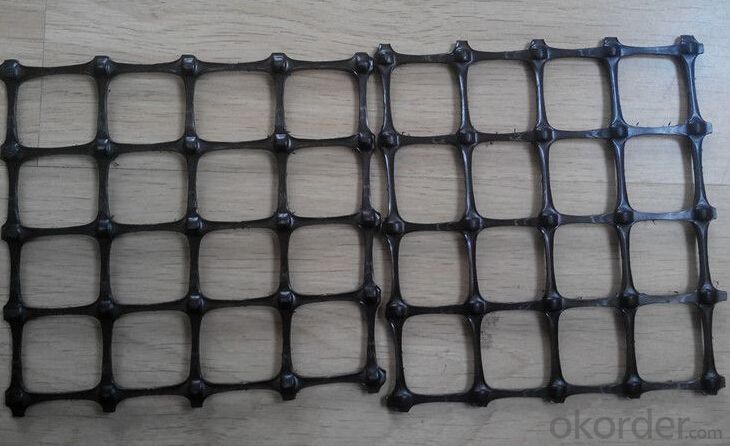

Plasticgeogrid is made of high molecular polymer after extruded and laminated and punched into regular mesh before longitudinal stretching.

The material on the longitudinal and transverse has great tensile strength, this kind of structure in the soil can also provide a more effectively undertake the chain and the spread of the thought system, suitable for large area of permanenet bearing foundation reinforcement.

2. Features of Plastic Geogrid

1). With high tensile strength in longitudinal and transverse directions

2).This structure can provide an chain system of more effective force bearing and spreading for the soil.

3. Application of Plastic Geogrid

Suitable for all kinds of dam and roadbed reinforcement, slope protection, The cave walls reinforcement, large airport, parking lot, wharf freight yard and other permanent bearing foundation reinforcement.

1). Increase road (ground) base bearing capacity and prolong the service life of road (ground).

2). Prevent road (ground) surface collapse or crack, ground is beautiful and tidy.

3). Construction is convenient, save time, effort, and shorten the construction period, reduce maintenance costs.

4). Prevent culvert crack.

5). Enhance soil, prevent soil erosion.

6). Reducing cushion thickness, saving the cost.

7). To support the stability of slope planting grass mat afforest environment.

8). Can replace the metal mesh, used in coal mine underground false roof net.

4. Technical Data and Specification of Plastic Geogrid

Spec Item | TGSG15-15 | TGSG20-20 | TGSG30-30 | TGSG40-40 | TGSG45-45 |

Longitudinal Tensile Strength ≥(KN/m) | 15 | 20 | 30 | 40 | 45 |

Transverse Tensile Strength≥(KN/m) | 15 | 20 | 30 | 40 | 45 |

Longitudinal Elongation≤(%) | 15 | ||||

Transverse Elongation≤(%) | 13 | ||||

Longitudinal Strength at 2% Strain ≥(KN/m) | 5 | 7 | 10.5 | 14 | 16 |

Transverse Strength at 2% Strain ≥(KN/m) | 5 | 7 | 10.5 | 14 | 16 |

Longitudinal Strength at 5% Strain ≥(KN/m) | 7 | 14 | 21 | 28 | 32 |

Transverse Strength at 5% Strain ≥(KN/m) | 7 | 14 | 21 | 28 | 32 |

Remark | Roll Length:50m Roll width:1~4m | ||||

5. RFQ:

1) What's your payment terms?

T/T, L/C at sight, etc

2) What's your delivery time?

Within 15-20days against your deposit or original L/C received

3) Can you accept third party test?

Yes, we can accept it totally, SGS, BSJ, etc are no problem for us.

- Q: What are the typical applications of geogrids in geotechnical engineering?

- Geogrids are commonly used in geotechnical engineering for various applications such as soil reinforcement, slope stabilization, retaining wall construction, and pavement reinforcement.

- Q: How do geogrids improve the stability of channel linings?

- Geogrids improve the stability of channel linings by providing reinforcement and preventing soil erosion. They enhance the tensile strength of the soil, reducing the risk of slope failure and increasing the overall stability of the channel lining.

- Q: What are the general laying methods of Geogrid

- Mechanism of glass fiber grid to prevent reflection crackThe above four methods are used to calculate the thickness of asphalt overlay on old cement concrete pavement. In order to prevent the occurrence of reflective cracks, the use of thick asphalt overlay. But relying solely on the increase of the overlay thickness has its drawbacks: on the one hand to increase the overlay thickness by the pavement elevation limit (Ningtong highway overpass bridge clearance in the overlay should meet the requirements of 4.8m); another is a substantial increase in the thickness of overlay will increase the cost of pavement, and under the condition of high temperature in summer the asphalt mixture high-temperature creep prone to rutting, will lose the advantage of strong foundation and thin surface due to the old cement concrete plate base generated, thus thickening asphalt overlay, this approach is not desirable.

- Q: Can geogrids be used in reinforcement of bridge abutments on soft clays?

- Yes, geogrids can be used in the reinforcement of bridge abutments on soft clays. Geogrids are commonly used as soil reinforcement materials to improve the stability and load-bearing capacity of weak or soft soils. They are effective in distributing loads and reducing soil settlement, making them suitable for reinforcing bridge abutments on soft clays.

- Q: Evaluation criteria and technical disclosure of geogrid.. Know how to share. Thank you

- 1) place: in the surface layer of 50cm thick sand gravel or sand (egg) gravel cushion, and compaction, which is not only conducive to improve the friction between the soil and the grid, but also conducive to the consolidation of the foundation drainage

- Q: How do geogrids improve the performance of unpaved roads?

- Geogrids improve the performance of unpaved roads by enhancing the stability and strength of the road base. They help distribute the load and prevent the lateral movement of soil particles, thereby reducing rutting and potholes. Geogrids also enhance the overall longevity of the road by reducing the need for maintenance and repair, making the road more durable and cost-effective in the long run.

- Q: Can geogrids be used in foundation stabilization?

- Yes, geogrids can be used in foundation stabilization. Geogrids are commonly used in civil engineering and construction projects to reinforce and stabilize soil and foundations. They provide additional tensile strength to the soil, preventing lateral movement and improving overall stability.

- Q: What is the meaning of the geogrid check bond frequency 2%

- This bond is really not heard, you say is not the kind of sticky,

- Q: Can geogrids be used in reinforcement of underground tunnels and caverns?

- Yes, geogrids can be used in the reinforcement of underground tunnels and caverns. Geogrids are commonly used in geotechnical engineering applications to improve soil stability and provide reinforcement. They can be installed as a reinforcement layer within the tunnel or cavern walls to enhance their structural integrity and prevent potential collapses or deformations. The geogrids act as a reinforcement material, distributing the loads and increasing the overall strength of the underground structures.

- Q: Are geogrids suitable for use in contaminated soil conditions?

- Yes, geogrids are suitable for use in contaminated soil conditions. Geogrids are made from durable and chemically resistant materials, which allows them to withstand the harsh conditions of contaminated soil. Additionally, their high tensile strength and stability make them effective in reinforcing and stabilizing the soil, even in contaminated areas.

Send your message to us

Geocells Philippines - Black Poly HDPE Geogrid and PP Biaxial Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords