PP Biaxial Geogrid with CE certification

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

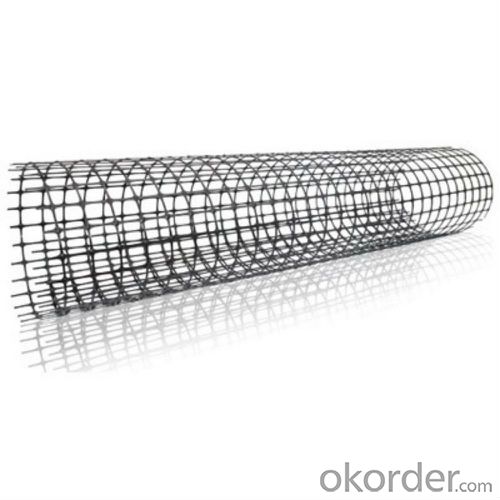

PP Biaxial Geogrid

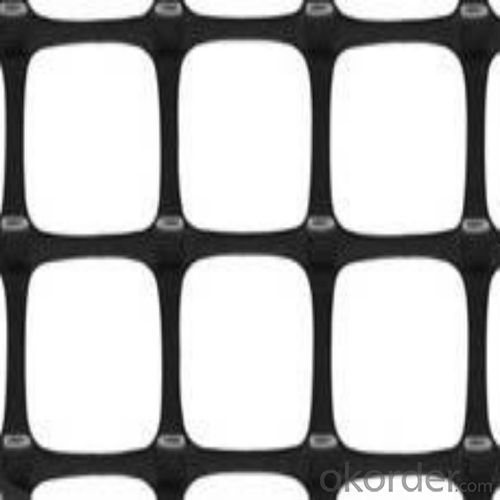

Introduction of PP Geogrid:

PP Biaxial geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching.This material has considerable tensile strength in longitudinal and lateral directions.This chain structure can effctively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Advantages of PP Geogrid:

-Improve roadbed bearing capacity, enlarge road lifetime

-Prevent road collapse and crack

-Prevent soil and water loss in slope

-Could replace steel-plastic geogrid in coal mine

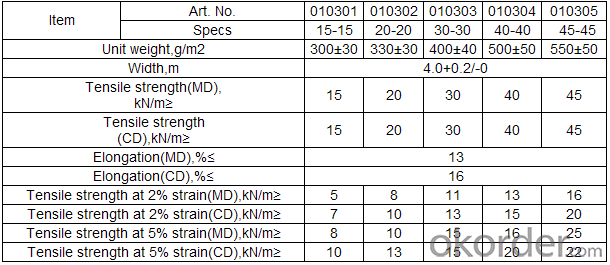

Specification of PP Geogrid:

-Raw material: PP

-Width(m): 1-6

-Length(m): 50-100

-Mesh size(mm): 30-50

Applications of PP Geogrid:

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

FAQ:

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway and dam etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

3. Which payment do you accept?

For you convinience,our payment can be L/C,TT

4. Is free sample available?

We can supply free samples for you. You just need to pay for express cost.

Photos of PP Geogrid and Factory:

- Q: Can geogrids be used in reinforcement of bridge abutments on soft clays?

- Yes, geogrids can be used in the reinforcement of bridge abutments on soft clays. Geogrids are commonly used in geotechnical engineering as a soil reinforcement material. When placed in soft clay soils, they can improve the stability and strength of the soil, providing additional support to bridge abutments and preventing excessive settlement or failure. By distributing the load more evenly and increasing the bearing capacity of the soil, geogrids can effectively reinforce bridge abutments on soft clays.

- Q: Light material, wear resistance, chemical stability, light oxygen aging, acid and alkali resistance, suitable for different soil and desert soil conditions.

- EM2 for the 2 layer, there are also EM3.EM4......

- Q: Can geogrids be used in green roof systems?

- Yes, geogrids can be used in green roof systems. Geogrids provide reinforcement and stability to the soil and vegetation layers of a green roof, preventing soil erosion and enhancing the structural integrity of the system. They can help distribute the weight of the green roof evenly, reduce the risk of subsidence, and improve overall performance and longevity.

- Q: Can geogrids be used in pipeline trench stabilization applications?

- Yes, geogrids can be used in pipeline trench stabilization applications. Geogrids are commonly used to improve soil reinforcement and provide stability to trenches, including those used for pipelines. They help to distribute loads, prevent soil erosion, and increase the overall strength of the trench.

- Q: What is the number of tensile elements of Geotextiles

- The number of tensile units in the test is the number of holes or the number of squares in the width of the test. For example, geotechnical geogrid 1m width of 25 holes, stretching the number of units is 25, the width of the sample is 200mm with a hole of 5, the number of tensile units of the sample is, C=Nm/Ns c=25/5=5 personal understanding is not necessarily more than

- Q: Can geogrids be used in temporary construction access mats for environmentally sensitive areas?

- Yes, geogrids can be used in temporary construction access mats for environmentally sensitive areas. Geogrids are a type of geosynthetic material that provides stability and reinforcement to the ground. They are often used in construction access mats to distribute loads and prevent soil erosion. Due to their low environmental impact and ability to protect the underlying soil, geogrids are suitable for use in environmentally sensitive areas where minimizing disturbance is crucial.

- Q: Do you need a geogrid to fill the stone roadbed?

- Please figure forAre generally required to do

- Q: How do geogrids help in reducing the need for excavation and grading?

- Geogrids help in reducing the need for excavation and grading by providing soil stabilization and reinforcement. They are typically made of high-strength materials and are placed within the soil to improve its load-bearing capacity. By distributing the weight and stress more evenly, geogrids prevent soil erosion, improve slope stability, and minimize settling, reducing the need for extensive excavation and grading work.

- Q: What is the recommended overlap for geogrid installation?

- The recommended overlap for geogrid installation is typically 1 to 2 feet or 30 to 60 centimeters.

- Q: High strength geogrid reinforced cloth, steel plastic grille, PET polyester grille, PP welded geogrid, steel plastic composite tensile band, where are these geosynthetics produced?

- Geogrid is a kind of main geosynthetics, compared with other geosynthetics,

Send your message to us

PP Biaxial Geogrid with CE certification

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords