HDPE Geocells Reinforced Polyester Geogrid for Road Surfaces Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

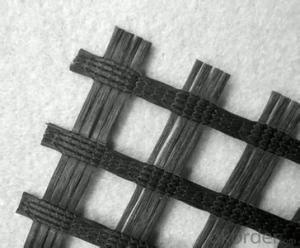

Knitting Polyester Geogrid Introduction:

Polyester geogrid is a new material for reinforce road base, it made by polyester fiber filament, and covered by special solution. High longitudinal and horizontal strength, low elongation rate, anti-alkali and aging resistance.

Specification | Tensile Strength KN/M longitude latitude | Percetage Elongation ≤ % | Covering Rate ≥ % | |

100×120 | 120 | 100 | 10 | 20 |

100×100 | 100 | 100 | 10 | 20 |

80×80 | 80 | 80 | 10 | 20 |

80×50 | 80 | 50 | 10 | 20 |

50×50 | 50 | 50 | 10 | 20 |

50×35 | 50 | 35 | 10 | 20 |

40×40 | 40 | 40 | 10 | 20 |

30×30 | 30 | 30 | 10 | 20 |

20×20 | 20 | 20 | 10 | 20 |

100 | 100 | 10 | 10 | 20 |

80 | 80 | 10 | 10 | 20 |

50 | 50 | 10 | 10 | 20 |

40 | 40 | 10 | 10 | 20 |

Features:

1) Adopting high-strength and high-modulus polyester or glass fibre, it is

knitted into loom-state grid fabric by warp knitting and processed into

grid by coating modified bitumen

2) It is used for reinforcing bitumen and cement pavements, and

for widening roads

3) Material: polyester

4) Strength: 50kN/m

5) Extensibility:<10%

Packing:

50m, 100m/roll, or according customers' requests

Warp Knitted Polyester Geogrid

Product Description:

Highintension, high tenacity, high occlusive force with soil or gravel,erosion-resistant, water drainage, light weigh

Reinforcesoft soil roadbed, rib side slope of embankment, enhance isolation, inhibitground deformation, prevent crack by reflection, increase strength of roadbed.

Engineering application:

1.reinforcementof road and railway, crack prevention, increase of roadbed str Roadbed ength,

2.Reinforcementand stabilization of riverside, embankment and side slope.

3.Dykereinforcement on soft ground for stress evenness, sedimentation adjustment,increase of stability and loading

capacity of fundus.

4.Reinforcement of the surface of road and bndge.

In a word, high quality Knitting Polyester Geogrid.

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

- Q: What are the factors that influence the design and selection of geogrids for reinforcement?

- The factors that influence the design and selection of geogrids for reinforcement include the type and properties of the soil, the load and traffic conditions, the desired level of reinforcement, the project lifespan, the installation and construction method, and the environmental conditions.

- Q: Glass fiber grille is not geogrid

- According to the material of a kind of Geogrid

- Q: What kind of projects are used to detect the geogrid

- Appearance, physical properties (including: Determination of mass per unit area, amplitude measurement, mesh size measurement); mechanical properties (including: tape tensile test, joint / joint wide strip tensile test, solder joints)

- Q: What are the procedures for using two-way geogrid

- 1 bidirectional geogrid is used to increase the bearing capacity of the road (ground) foundation, and the service life of the Yan Changlu (ground) foundation.2 bidirectional geogrid used to prevent road (ground) surface collapse or crack, keep the ground beautiful and tidy.3 bidirectional geogrid for the construction of convenient, time-saving, labor-saving, shorten the construction period, reduce maintenance costs.

- Q: Can geogrids be used in subgrade stabilization applications?

- Yes, geogrids can be used in subgrade stabilization applications. Geogrids are often used to reinforce and stabilize the soil in subgrade areas, improving their load-bearing capacity and preventing soil movement. By distributing the load across a larger area, geogrids help to reduce settlement and increase the overall stability of the subgrade.

- Q: Can geogrids be used in floating road construction?

- Yes, geogrids can be used in floating road construction. Geogrids are commonly used as reinforcement materials in road construction to improve the stability and load-bearing capacity of the road. In floating road construction, geogrids can be used to enhance the structural integrity and prevent the road from sinking or shifting in unstable soil conditions, such as marshy or soft ground. By providing reinforcement and distributing the load, geogrids help to create a stable foundation for the floating road, making them a valuable component in this type of construction.

- Q: What are the factors to consider when selecting geogrids for a project?

- When selecting geogrids for a project, it is important to consider factors such as the site conditions, load requirements, and the desired application. The site conditions, including soil type, slope stability, and groundwater levels, will determine the type and strength of geogrid needed. Load requirements, such as traffic or equipment loads, will impact the geogrid's tensile strength and durability. Additionally, considering the desired application, such as soil stabilization, retaining walls, or erosion control, will help determine the appropriate geogrid material and design.

- Q: Characteristics of steel plastic geogrid

- 1 high strength steel wire, steel plastic composite geogrid tension by warp knitting bear, resulting in high tensile modulus at low strain capacity, vertical and horizontal rib synergistic effect, give full play to the role of Geogrid on soil type.2, steel plastic composite geogrid vertical wire warp rib braided mesh, an outer coating layer forming a steel wire and the outer coating layer can destroy the function of coordination, elongation is very low (less than 3%). The main force unit of steel plastic composite geogrid is steel wire, and the creep is very low.

- Q: GDZ150 type one-way steel plastic welding geogrid D in the construction of the roadbed is horizontal paving also vertical spread?

- Because the direction of the force is mainly perpendicular to the direction of the line, your product is a one-way force of the product; if two-way products do not exist this problem.

- Q: What are the models and specifications of Geogrid for road

- But the specifications are not necessarily the same as the national standard.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

HDPE Geocells Reinforced Polyester Geogrid for Road Surfaces Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords