3 8 In Aluminum Plate

3 8 In Aluminum Plate Related Searches

3 8 Aluminum Plate 1 8 In Aluminum Plate 3 8 Inch Aluminum Plate 3/8 In Aluminum Plate 3 8 Thick Aluminum Plate 3 8 Inch Thick Aluminum Plate 1 8 Aluminum Plate 3 8 Aluminum Diamond Plate 3 8 Diamond Plate Aluminum 3/8 Aluminum Plate 5 8 Aluminum Plate 3/8 Inch Aluminum Plate 3/8 Aluminum Plate 4x8 1 8 Inch Aluminum Plate 3/8 Thick Aluminum Plate Aluminum Plate 3/8 Thick 8 Inch Aluminum Plate 3 16 Aluminum Plate 4x8 1/8 In Aluminum Plate 1 8 Thick Aluminum Plate 1 8 Inch Thick Aluminum Plate 3 8 Aluminum Plate Weight 4 8 Aluminum Diamond Plate 3 4 Aluminum Plate Aluminum 1/8 Plate 3/8 Aluminum Diamond Plate 1 8 Aluminum Diamond Plate 3/8 Aluminum Plate Near Me 3/16 Aluminum Plate 4x8 3 8 Aluminum Bar Stock3 8 In Aluminum Plate Supplier & Manufacturer from China

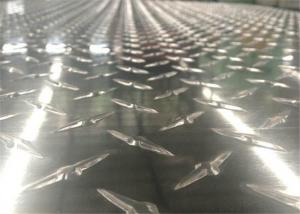

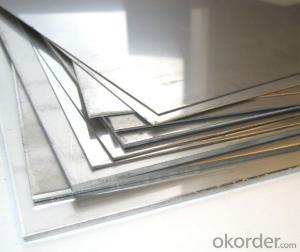

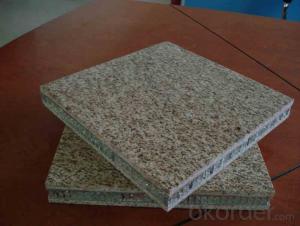

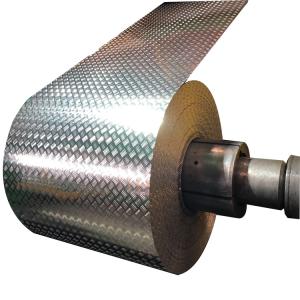

3/8 in Aluminum Plate is a versatile product that is widely used in various industries due to its lightweight, corrosion-resistant, and high-strength properties. This type of aluminum plate is ideal for applications that require a balance between durability and weight, such as in the construction, automotive, and aerospace industries. The 3/8 in Aluminum Plate is available in different grades, allowing customers to choose the most suitable option for their specific needs.The 3/8 in Aluminum Plate is commonly used in fabrication processes, such as welding, cutting, and bending, to create components and structures that can withstand harsh environments and heavy loads. Its non-magnetic and non-sparking characteristics also make it a popular choice for applications in the oil and gas industry, where safety is a top priority. Additionally, the 3/8 in Aluminum Plate can be easily anodized or painted, allowing for customization in terms of appearance and corrosion resistance.

Okorder.com is a reputable wholesale supplier of 3/8 in Aluminum Plate, offering a vast inventory of this product to cater to the needs of various industries. With their extensive selection and competitive pricing, customers can rely on Okorder.com to provide high-quality 3/8 in Aluminum Plate for their projects. The company's commitment to customer satisfaction and efficient delivery ensures that clients receive their orders promptly and in excellent condition.

Hot Products