China 4 By 8 Sheets of Aluminum Prepainted for Light Colorful Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Prepainted for Light Corlorful Making Description:

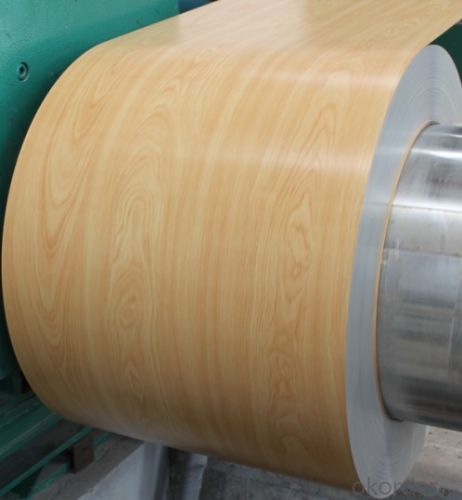

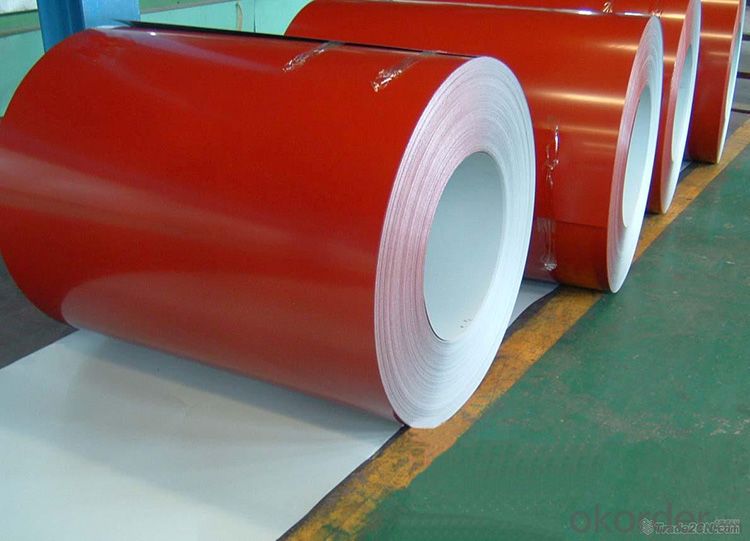

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted for Light Corlorful Making:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Prepainted for Light Corlorful Making:

Aluminium Prepainted for Light Corlorful Making Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Prepainted for Light Corlorful Making:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How to distinguish aluminum sheet from magnesium sheet?

- magnesium sheet will react with alkali.

- Q: If not, where can i buy some aluminum?

- some contraptions do not use radio waves, a CD participant as an occasion. Radio waves are flying around everywhere, and can intervene with a number of the comfortable singals interior those contraptions, so we want a thank you to dam the waves. some contraptions produce radio-waves, not as an meant output of the gadget, yet as a byproduct of yet another function. Your computing device is an occasion of this. And those contraptions can intervene with the operation of contraptions that are interior attain, like your cellular telephone. So we could give up those by probability produced waves from getting out of the computing device. and in specific circumstances a factor of a gadget makes use of radio waves on a similar time as yet another area of a similar gadget would not, and could be shielded from the different area or it won't artwork right.

- Q: Can aluminum sheets be coated with protective films?

- Indeed, it is possible to coat aluminum sheets with protective films. Typically, these films are composed of materials like polyethylene or polypropylene and serve the purpose of creating a defense against scratches, abrasions, and additional types of harm. By applying the protective film onto the aluminum sheet's surface, a safeguarding layer is formed, shielding it from any potential damage that may occur during handling, transportation, or processing. Through this coating process, the aluminum sheet's integrity and appearance are preserved, guaranteeing that it remains in impeccable condition until it is prepared for utilization.

- Q: This is kind of odd, but if a volcano erupted and the lava dripped into an aluminum can, would the can melt? Would the lava harden and cool in it?

- Temperature of lava - 700 degrees Celsius. Melting point of aluminum - 660 degrees Celsius. I'll let you figure out if the can would melt...

- Q: Is it possible to utilize aluminum sheets in the construction of furniture?

- <p>Yes, aluminum sheets can be used for furniture. They are lightweight, durable, and resistant to corrosion, making them suitable for various types of furniture such as outdoor furniture, tables, chairs, and shelving. Aluminum's strength and flexibility allow for creative designs and easy maintenance. Additionally, it is a sustainable material that can be recycled, contributing to environmental sustainability.</p>

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean. Aluminum is a non-porous material, which means that it does not absorb liquids or stains easily. This makes it relatively easy to wipe off dirt, dust, or spills from the surface of aluminum sheets using a damp cloth or sponge. Additionally, aluminum is resistant to rust and corrosion, so it does not require any special cleaning agents or treatments. However, it is important to note that abrasive cleaners or scrubbing pads should be avoided as they can scratch the surface of the aluminum. Overall, with regular maintenance and proper cleaning techniques, aluminum sheets can be kept clean and in good condition for a long time.

- Q: bending, bending phenomenon will occur, I would like to annealing treatment. Does the master know the annealing temperature and time?

- And the same direction in the rolling, more than 1.5 of the thickness of cracking is more serious; it is proposed to increase the bending angle of R, annealing may not be solved.Or on the bending line and calendering line to cross 45 degrees (comparison fee)

- Q: Its been bugging me for years and i want to know why they say aluminum and not aluminium like it is spelt in the Oxford English dictionary and more importantly the universal periodic table, accepted by all countries, does anyone know why? I would like all opinions on this matter, if possible, thank you

- Aluminum okorder /... It’s clear that the shift in the USA from –ium to –um took place progressively over a period starting in about 1895, when the metal began to be widely available ... The American Chemical Society only adopted it in 1925, though this was clearly in response to the popular shift that had already taken place.

- Q: Are aluminum sheets suitable for lightweight structures?

- Yes, aluminum sheets are suitable for lightweight structures. Aluminum is known for its low density and high strength-to-weight ratio, making it an ideal material for lightweight applications. Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction, where weight reduction is crucial. They offer excellent corrosion resistance, durability, and formability, allowing for easy fabrication and installation. Additionally, aluminum sheets can be easily joined using various welding and adhesive techniques, further enhancing their suitability for lightweight structures.

- Q: Can aluminum sheets be used for elevator interiors?

- Yes, aluminum sheets can be used for elevator interiors. Aluminum is a commonly used material in elevator construction due to its durability, lightweight nature, and aesthetic appeal. It provides a sleek and modern look to elevator interiors while also offering high resistance to corrosion and wear.

Send your message to us

China 4 By 8 Sheets of Aluminum Prepainted for Light Colorful Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords