3 16 Diamond Plate Aluminum Sheets C.C 3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets C.C 3XXX Description

Aluminum Sheets C.C 3XXX is cut from aluminum coils 3xxx. Aluminum Sheets C.C 3XXX has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets C.C 3XXX is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminum Sheets C.C 3XXX

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

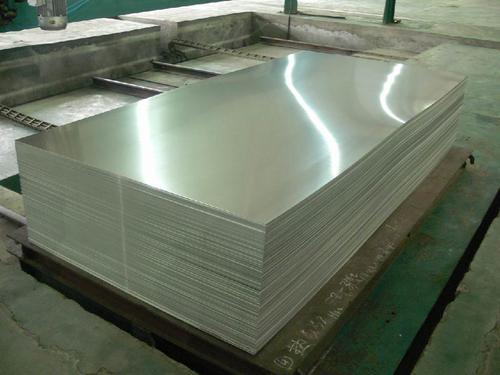

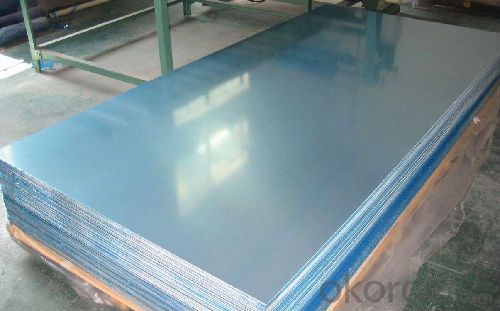

3.Aluminum Sheets C.C 3XXX Images

4.Aluminum Sheets C.C 3XXX Specification

| Alloy | AA3xxx (AA3003,AA3004,AA3005,AA3105 etc) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ ofAluminum Sheets C.C 3XXX

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the Aluminum Sheets C.C 3XXX products.

B.When will you deliver the products?

The Aluminum Sheets C.C 3XXX will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What is the typical impact strength of aluminum sheets?

- The impact strength of aluminum sheets can differ depending on the alloy and temper of the material. Nevertheless, when compared to other metals, aluminum sheets generally possess a relatively lower impact strength. This is due to the fact that aluminum, being a lightweight material, lacks the strength and durability of steel or other alloys. To measure the impact strength of aluminum sheets, one typically determines the energy required to cause the material to fracture or deform, which can be expressed in joules or foot-pounds. Although specific values may vary, the impact strength of aluminum sheets typically falls within the range of 10 to 40 joules or 7 to 30 foot-pounds. It is worth noting that factors such as thickness, surface condition, and the presence of surface treatments or coatings can influence the impact strength. Therefore, it is advisable to consult the manufacturer's specifications or conduct specific tests to ascertain the impact strength of a particular aluminum sheet.

- Q: I've narrowed down my next bike next year to either the cannondale Caad10 Ultegra version or the supersix 105 version, I've heard good things about both bikes, and at this point its gonna be down to preference after I ride it but, is aluminum stronger than carbon or vice versa? Will carbon crack easily or fail catastrophically?

- Aluminum Vs Carbon Road Bike

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, as long as proper techniques such as annealing and using appropriate tooling are employed.

- Q: What are the advantages of using aluminum sheet in construction?

- Using aluminum sheet in construction offers several benefits. Firstly, its lightweight composition makes it easy to handle and transport on construction sites, reducing the need for heavy machinery and improving efficiency, ultimately leading to cost savings. Secondly, aluminum exhibits exceptional resistance to corrosion, unlike other metals such as steel, making it a durable and suitable material for outdoor applications like roofing or cladding. Additionally, aluminum's versatility allows for easy shaping and forming into various sizes and profiles, providing architects and engineers with greater design flexibility to create innovative and unique structures. Moreover, aluminum is a sustainable choice as it is 100% recyclable, helping reduce waste and minimize the carbon footprint. Furthermore, it possesses excellent thermal and electrical conductivity properties, reflecting heat and light to maintain comfortable indoor temperatures and reduce energy consumption. It also serves as an excellent conductor of electricity, making it ideal for electrical wiring and building components. Lastly, though aluminum may have a higher initial cost, its low maintenance requirements and long lifespan make it cost-effective in the long run. Structures made with aluminum sheet do not require regular painting or upkeep, saving both time and money. In conclusion, the advantages of utilizing aluminum sheet in construction encompass its lightweight nature, corrosion resistance, versatility, sustainability, thermal and electrical conductivity, and cost-effectiveness, making it highly desirable for a wide array of construction applications.

- Q: Is plastic or alumium container more harmful to store food in if it does get to the food while heating.

- I have read that some plastics have estrogen in them. Causing an excess in either sex can cause serious problem, men especially. Autopsy's of people who had Alzheimer's show aluminum in their brains. Life is definitely a challenge.

- Q: How much is the aluminum plate shearing machine?

- Aluminum plate is soft, want to blade better, or it is easy to cut askew, and the size according to type, shearing machine size, and there is configuration to set, Jiangsu Germany forging has sold as if

- Q: which kind of abraser should be used for deburring of aluminum sheet?

- you can use soft resin grinding stone.

- Q: Can aluminum sheets be used for decorative ceiling panels?

- Yes, aluminum sheets can be used for decorative ceiling panels. Aluminum is a versatile material that offers many benefits for this purpose. It is lightweight, durable, and corrosion-resistant, making it suitable for long-term use. Additionally, aluminum sheets can be easily shaped and molded into various designs, patterns, and textures to create visually appealing ceiling panels. These panels can be finished with different coatings or finishes to enhance their aesthetic appeal and match the desired decor style. Furthermore, aluminum is a sustainable and eco-friendly material as it can be recycled, making it an ideal choice for those who prioritize environmental consciousness. Overall, aluminum sheets are an excellent option for decorative ceiling panels due to their versatility, durability, and aesthetic potential.

- Q: Can the aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be easily bent or formed into different shapes. Aluminum is a highly malleable metal, meaning it can be easily manipulated without breaking or cracking. This property makes it ideal for various applications where flexibility and customization are required. Aluminum sheets can be bent, folded, rolled, or formed using a variety of techniques such as press brakes, rollers, or specialized forming tools. This versatility allows for the creation of complex shapes and structures, making aluminum a popular choice in industries like construction, automotive, aerospace, and manufacturing.

- Q: How strong is aluminum per square inch, and at the same time how light is the aluminum per square inch?

- Take a look on this website. You will see some of the main uses of aluminium and will be able to determine what it is capabke of: www.bwcaluminium .uk

Send your message to us

3 16 Diamond Plate Aluminum Sheets C.C 3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords