Aluminum Composite Panel 8XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

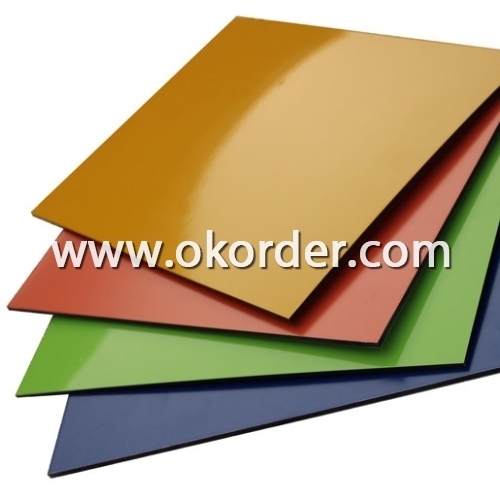

Specifications of Aluminium Composite Panel 8xxx

1.Coating: PVDF/PE

2.Core: unbreakable/ breakable LDPE core

3.ISO9001:2000 and SGS certificate

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope of aluminium composite panel 8xxx:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 40 days after getting the buyer's payment.

Repeat rolling - Cleaning - Pretreatment – Coating - Inspection - Film production - Plastic extruding – Compositing - Packing

- Q: This question asks for methods to effectively clean aluminum surfaces without causing damage.

- <p>To clean aluminum surfaces effectively, use a mild detergent and warm water. Mix a few drops of dish soap with water in a bucket. Dip a soft cloth or sponge into the solution and gently wipe the aluminum surface. Avoid using abrasive materials or harsh chemicals, as they can scratch the surface. After cleaning, rinse with water and dry thoroughly to prevent water spots. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. Regular cleaning will help maintain the surface's appearance and prevent corrosion.</p>

- Q: This question asks about the energy consumption involved in the manufacturing process of an aluminum can.

- <p>The energy required to process and produce an aluminum can varies based on factors like production scale and technology used. On average, it takes about 70-90 kilowatt-hours (kWh) of energy to produce a single aluminum can. This includes the energy for mining bauxite, refining it into alumina, smelting it into aluminum, and finally, manufacturing the can. The energy consumption is significantly lower compared to producing cans from other materials like steel or plastic, which makes aluminum cans more energy-efficient.</p>

- Q: This question asks for a list of typical aluminum alloys that are widely used in various industries.

- <p>Common types of aluminum alloys include 1000 series, which are nearly pure aluminum; 2000 series, known for their strength due to copper content; 3000 series, which are alloyed with manganese for good formability; 5000 series, featuring magnesium for improved strength and corrosion resistance; 6000 series, which are popular for their strength and heat treatability; and 7000 series, recognized for their highest strength among aluminum alloys, often used in aerospace and automotive applications. Each series offers unique properties that make them suitable for specific applications.</p>

- Q: This question asks about the impact of adding silicon to aluminum alloys on their characteristics.

- <p>Adding silicon to aluminum alloys significantly enhances their properties. Silicon increases the alloy's strength and hardness, making it more durable. It also improves the alloy's resistance to corrosion, particularly in harsh environments. The addition of silicon can also reduce the melting point of the alloy, which can be beneficial for casting processes. However, it should be noted that excessive silicon content can lead to a decrease in ductility and workability of the alloy. Overall, silicon is a common alloying element used to improve the mechanical properties and performance of aluminum alloys in various applications.</p>

- Q: Explain how aluminum influences the propagation of sound waves.

- <p>Aluminum has a high density and stiffness, which makes it an effective conductor of sound. When sound waves hit an aluminum surface, the vibrations are quickly transmitted through the material due to its low internal damping. This results in a clear and efficient transfer of sound energy. However, aluminum's high reflectivity can also lead to a significant amount of sound being reflected rather than absorbed, which can affect the acoustics in a space, potentially causing echoes or reducing sound absorption. Additionally, aluminum's conductivity can lead to a faster decay of sound within the material, impacting the duration and quality of sound transmission.</p>

- Q: This question asks for an explanation of the environmental effects caused by the process of smelting aluminum.

- <p>The environmental impact of smelting aluminum is significant. It is an energy-intensive process that contributes to greenhouse gas emissions, primarily due to the high electricity consumption required for the Hall-H茅roult process. This process also generates perfluorocarbons (PFCs), which are potent greenhouse gases. Additionally, the production of aluminum releases particulate matter and sulfur dioxide, contributing to air pollution. The extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Moreover, the waste products, such as red mud, can cause water pollution if not properly managed. Overall, the smelting of aluminum has considerable environmental implications, necessitating the development of more sustainable practices in the industry.</p>

- Q: Is it possible to utilize aluminum in the manufacturing of tools and equipment?

- <p>Yes, aluminum can be used to make tools and equipment. It is valued for its lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum is commonly used in various applications such as aircraft manufacturing, automotive parts, and consumer electronics. It is also used in the construction of certain types of tools, particularly those that require lightness and durability without the need for extreme strength. However, for applications requiring high strength or resistance to high temperatures, other materials might be more suitable.</p>

- Q: Is it safe to use aluminum containers for food and drink in a microwave?

- <p>Aluminum is not recommended for use in microwave-safe containers for food and drink. While some aluminum containers are designed to be microwave-safe, they are typically coated with a non-metallic material to prevent arcing and damage to the microwave. However, most aluminum containers are not safe for microwave use as they can cause sparks and potentially damage the microwave. It's best to use microwave-safe plastics, glass, or ceramics specifically designed for microwave use.</p>

- Q: Explain the economic and job market implications of using aluminum.

- <p>The use of aluminum has significant impacts on the economy and job market. It is a key material in various industries, including construction, automotive, aerospace, and consumer goods, which drives demand and economic growth. Aluminum production and processing create jobs directly in mining, refining, and manufacturing sectors, and indirectly in related services and supply chains. Additionally, its lightweight and corrosion-resistant properties make it valuable for energy-efficient transportation, contributing to environmental sustainability and opening new job opportunities in green technologies. However, it also presents challenges such as the need for energy-intensive production processes and the management of waste, which require innovative solutions and can lead to job creation in recycling and environmental management.</p>

- Q: Is there an alternative method for recycling aluminum besides the conventional process?

- <p>Yes, aluminum can be recycled using different processes. While the conventional process involves melting and recasting, alternative methods include mechanical recycling, which involves shredding and reusing aluminum without melting, and chemical recycling, which breaks down aluminum into its base elements and reassembles them into new products. These methods can be more energy-efficient and environmentally friendly, depending on the specific circumstances and technologies used.</p>

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Composite Panel 8XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords