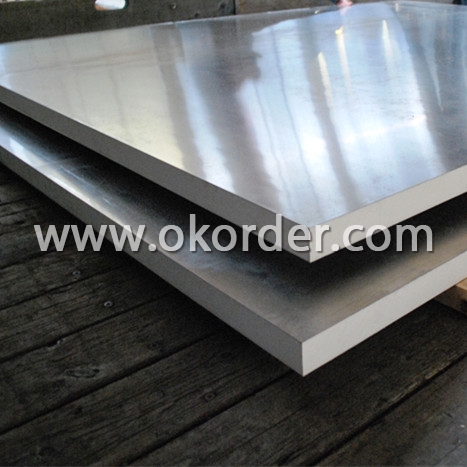

China Manufacturer of High Quality Aluminum Plates 3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High-grade Aluminum Plates Usage and Applications

These Aluminum Plates are between 0.1 to 500 mm in thickness and have a wide variety of uses in the construction industry such as aluminium siding and roofing.

The Aluminum Sheets are also widely used in construction, decorations, transport applications, automobile body panels, airframes, curtain walls, ship hulls and much more.

OKorder supplies only the highest grade of Aluminum Plates that are certified, quality assured, and meet the highest international standards. The Aluminum Products complies with YS/T 429-2000 (Chinese Industry Standard), GB/T 3880, EN485, & ASTM B209.

High-grade Aluminum Plates Specifications

Alloy Number: AA3003, AA3004, AA3005, AA3015

Temper: H12, H14, H16, H18, H22, H24, H26, H32, HO, F

Thickness: 0.1 to 500 mm

Width: 10 x 2200 mm

Standard: GB/T3880-2006, ASTM, ISO, EU standard

- Note: Custom specification is available upon request

- Q: What is the maximum temperature that aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can tolerate relies on various factors, including the composition of the alloy, thickness, and intended purpose. Generally, aluminum has a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit). Nevertheless, aluminum sheets can typically endure significantly higher temperatures without melting or distorting. Regarding most commercially available aluminum alloys, the maximum temperature for continuous utilization varies from 200 to 300 degrees Celsius (390 to 570 degrees Fahrenheit). Beyond this range, the material might begin to display reduced strength and heightened vulnerability to deformation or harm. Nevertheless, it is crucial to mention that the precise maximum temperature limit for a specific aluminum sheet should be determined by referring to the manufacturer's specifications or conducting specific testing. Factors like the presence of coatings or surface treatments, exposure to prolonged heat, and thermal cycling can also influence the maximum temperature tolerance of aluminum sheets.

- Q: What are the different types of patterns available for aluminum sheets?

- There are a variety of patterns available for aluminum sheets, each offering a unique aesthetic and functional appeal. Some commonly found patterns include: 1. Diamond Pattern: This pattern features a series of raised diamonds formed by parallel lines that intersect at 60-degree angles. It provides excellent slip resistance and is commonly used for flooring, stairs, and walkways. 2. Stucco Pattern: The stucco pattern consists of a textured, pebble-like surface that resembles traditional stucco plaster. It offers enhanced durability and is often used for decorative purposes on walls, ceilings, and interior panels. 3. Hammered Pattern: The hammered pattern showcases a hammered or dimpled texture, giving the aluminum sheet a rustic and artistic appearance. It is frequently used for decorative purposes, such as wall cladding or furniture accents. 4. Perforated Pattern: Perforated aluminum sheets feature a pattern of small holes, offering excellent ventilation and visibility. They are commonly used in architectural applications such as facades, sunscreens, and noise barriers. 5. Embossed Pattern: The embossed pattern involves raised designs or patterns on the sheet's surface, adding depth and visual interest. It is used for decorative purposes, signage, and branding applications. 6. Brushed Pattern: The brushed pattern is achieved by creating a uniform directional grain on the aluminum sheet's surface. It provides a sleek and modern appearance, often used for architectural accents, kitchen backsplashes, and appliances. 7. Ribbed Pattern: The ribbed pattern consists of parallel raised ridges or lines on the sheet's surface. It offers improved strength and rigidity, making it suitable for applications requiring structural support or reinforcement. These are just a few examples of the various patterns available for aluminum sheets. Different patterns serve different purposes, so it is important to consider the specific requirements and desired aesthetic when selecting the appropriate pattern for a particular application.

- Q: How do aluminum sheets perform in terms of electrical conductivity?

- Aluminum sheets are known for their excellent electrical conductivity. They are highly conductive, ranking second only to copper in terms of electrical conductivity among common metals. This high conductivity makes aluminum sheets an ideal choice for various electrical applications, including wiring, power transmission, and electrical components. The low resistivity of aluminum allows for efficient transfer of electricity, ensuring minimal energy loss during transmission. Additionally, aluminum sheets are lightweight, making them a preferred material for electrical systems where weight reduction is desired. Overall, aluminum sheets offer exceptional electrical conductivity, making them a reliable and efficient choice for electrical applications.

- Q: What are the different thickness tolerances for aluminum sheets?

- The thickness tolerances for aluminum sheets can vary depending on the specific grade and manufacturing process, but generally they range from ±0.005 inches to ±0.015 inches.

- Q: which is the best bonding method for aluminum sheet and plastic?

- smear glue, there is a glue special for the bonding of plastic and steel materials.

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Yes, aluminum sheets are suitable for pharmaceutical applications. Aluminum is a widely used material in the pharmaceutical industry due to its various beneficial properties. Firstly, aluminum sheets are lightweight and have excellent corrosion resistance. This makes them ideal for packaging pharmaceutical products as they can protect the contents from external factors such as moisture, light, and oxygen, which could potentially degrade the quality of the medication. Additionally, aluminum sheets can be easily formed into different shapes and sizes, allowing for customization in packaging design. They are also available in various thicknesses, providing options for different types of pharmaceutical products, from tablets and capsules to liquid medications. Furthermore, aluminum sheets have a high barrier property, effectively preventing the transfer of odors, flavors, and contaminants. This ensures the integrity and safety of the medication throughout its shelf life. Moreover, aluminum is a non-toxic material, which means it does not react with drugs or alter their composition. This makes it a suitable choice for pharmaceutical applications, where maintaining the purity and stability of the medication is crucial. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications due to their lightweight, corrosion resistance, barrier properties, and non-toxic nature. They provide efficient protection and preservation of pharmaceutical products, ensuring their quality and safety.

- Q: Can the aluminum sheets be used for packaging applications?

- Yes, aluminum sheets can be used for packaging applications. Aluminum is a versatile material that offers several benefits for packaging. It is lightweight, yet strong and durable, making it ideal for protecting and preserving various products, including food, beverages, pharmaceuticals, and cosmetics. Aluminum sheets can be easily formed into different shapes and sizes, allowing for customized packaging solutions. Additionally, aluminum has excellent barrier properties, providing a protective barrier against moisture, oxygen, light, and other contaminants, which helps to extend the shelf life of the packaged products. The material is also recyclable, making it an environmentally friendly choice for packaging applications. Overall, aluminum sheets are widely used in the packaging industry due to their versatility, strength, durability, barrier properties, and recyclability.

- Q: How are aluminum sheets manufactured?

- Aluminum sheets are manufactured through a process called rolling. The process starts with aluminum ingots, which are heated and then passed through a series of rolling mills. These mills apply pressure to the ingots, reducing their thickness and lengthening them at the same time. As the ingots pass through the mills, they are gradually transformed into thin sheets of aluminum. The rolling mills consist of a series of rollers, which are typically made of steel. The rollers rotate in opposite directions, and as the aluminum passes between them, it is squeezed and stretched. This continuous process of rolling helps to refine the aluminum's grain structure and improve its mechanical properties. To ensure the proper thickness and surface finish, the aluminum sheets may go through multiple passes in the rolling mills. Each pass gradually reduces the thickness of the sheet until the desired thickness is achieved. The final pass also imparts the desired surface finish. After the rolling process, the aluminum sheets may undergo further treatments such as annealing or surface treatments to enhance their properties or appearance. Annealing involves heating the sheets to a specific temperature and then cooling them slowly to relieve internal stresses and improve their strength. Once the sheets are manufactured and treated, they are typically cut into desired sizes and shapes. This can be done through shearing, which involves cutting the sheets with sharp blades, or by using specialized cutting machines. Overall, the manufacturing of aluminum sheets is a complex and precise process that involves heating, rolling, and treating the aluminum to achieve the desired thickness, finish, and properties.

- Q: Are the aluminum sheets suitable for manufacturing heat exchanger tubes?

- Yes, aluminum sheets are suitable for manufacturing heat exchanger tubes. Aluminum has excellent thermal conductivity, corrosion resistance, and is lightweight, making it an ideal material for heat transfer applications.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. They offer several advantages such as high thermal conductivity, corrosion resistance, and lightweight nature, making them ideal for efficient heat transfer and durability in HVAC applications.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

China Manufacturer of High Quality Aluminum Plates 3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords