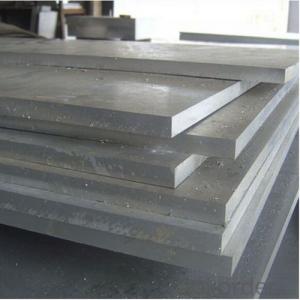

3/4 Inch Thick Aluminum Plate

3/4 Inch Thick Aluminum Plate Related Searches

3/4 Thick Aluminum Plate 3/4 Inch Aluminum Plate 1/4 Inch Thick Aluminum Plate 1/4 Thick Aluminum Plate 3/4 Aluminum Plate Aluminum Plate 1/4 Inch Thick 3 4 Thick Aluminum Plate Aluminum Plate 1/4 Thick 1 4 Inch Thick Aluminum Plate 1/4 Inch Aluminum Plate 3 4 Inch Aluminum Plate 1 4 Thick Aluminum Plate 1 4 Inch Aluminum Plate 1/4 Plate Aluminum 4 Inch Aluminum Plate 1/4in Aluminum Plate 1/4 Aluminum Plate Aluminum 1/4 Plate 1/2 Inch Thick Aluminum Plate 1/4 In Aluminum Plate 1/8 Inch Thick Aluminum Plate Aluminum Plate 1/4 Aluminum Plate 1/2 Inch Thick 1/4 Inch Diamond Plate Aluminum Aluminum Diamond Plate 1/4 Thick 3 4 Aluminum Plate 4 Mm Aluminum Plate 4 X 4 Aluminum Plate 1 4 Aluminum Plate 1/4 Inch Aluminum Plate 4x83/4 Inch Thick Aluminum Plate Supplier & Manufacturer from China

3/4 Inch Thick Aluminum Plate is a type of aluminum sheet material that is widely recognized for its durability and strength. It is available in various dimensions and grades, making it a versatile choice for numerous applications. This product is specifically designed to meet the demands of industries that require robust and lightweight materials for their projects.The 3/4 Inch Thick Aluminum Plate is commonly used in construction, aerospace, automotive, and marine industries due to its excellent corrosion resistance and high strength-to-weight ratio. It is ideal for applications such as structural components, exterior cladding, and fabrication of various parts that require both strength and lightness. Its ability to withstand harsh weather conditions and maintain its integrity over time makes it a popular choice for outdoor installations and equipment.

Okorder.com is a leading wholesale supplier of 3/4 Inch Thick Aluminum Plate, offering a vast inventory to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the aluminum plates are sourced from reputable manufacturers and are available at competitive prices. This makes it an ideal platform for businesses looking to purchase high-quality 3/4 Inch Thick Aluminum Plate for their projects.

Hot Products