Quarter Inch Aluminum Sheets for Solar Reflector Reflective Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Reflective Strips for Solar Reflector

l Product Introduction

The Aluminum Strip is mainly used for refrigerator, cable ,capacitor shell material, steal-protection cover, cable sheathing, composite pipe and tube, water pipe etc. It has the property of deep drawing, high thickness accuracy, and low earring rate, etc.

l Features of aluminum strip

It has excellent thickness uniformity, slitting quality and high purity

1. PP metalized film have excellent self-healing performance

2. The selvedge is thickened, the PP metalized film welded performance is fine

3. the margin could be customized freely

4. The thickness of plate could be adjusted conveniently

l Packaging & Delivery

Packaging detail: Covering with brown paper and plastic bag then packed with wooden plywood then directly loading into container for transshipment. For the thickness which is more than 1.50mm, one paper interleave into two sheets.

Delivery detail: within 30 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium Strip has always been one of the most popular products in CNBM. With advanced technic skills and equipment, CNBM has produced high quality aluminium strips that meet international standard.

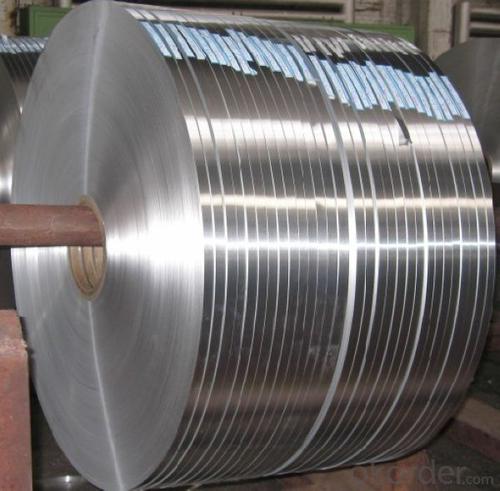

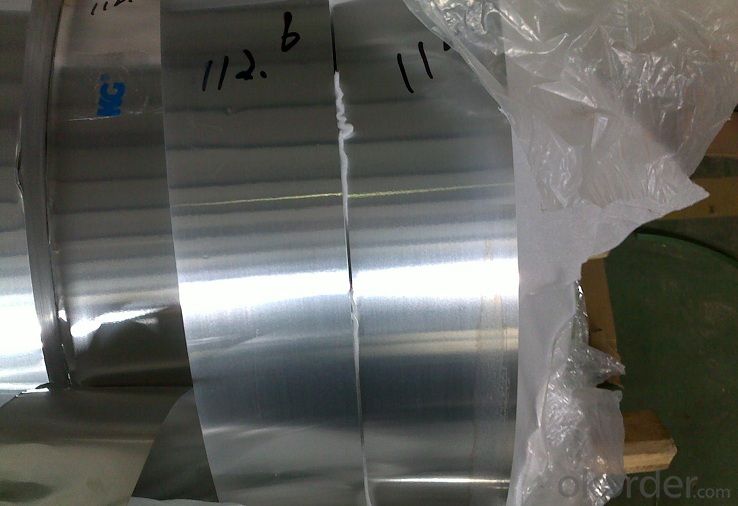

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What are the rules and standards that govern the use of aluminum sheets in construction projects?

- <p>Yes, there are regulations regarding the use of aluminum sheets in construction. These regulations vary by country and region but generally cover aspects such as material standards, safety, and environmental impact. For instance, in the United States, the American Society for Testing and Materials (ASTM) provides standards for aluminum sheet materials. Building codes like the International Building Code (IBC) also specify requirements for the use of aluminum in construction. These regulations ensure that aluminum sheets meet certain strength, durability, and performance criteria. Compliance with these regulations is crucial for safety, structural integrity, and to obtain necessary permits and approvals for construction projects.</p>

- Q: How do you prevent surface marring of aluminum sheets during handling?

- To prevent surface marring of aluminum sheets during handling, there are several steps you can take: 1. Use clean gloves or finger cots: When handling aluminum sheets, it is important to avoid direct contact with bare hands as they may contain oils, dirt, or other contaminants that can leave marks on the surface. Wearing clean gloves or finger cots can provide a barrier and prevent any transfer of substances onto the sheets. 2. Use protective packaging: Prior to handling, consider using protective packaging such as foam or plastic sheets to cover the surface of the aluminum sheets. This will provide an additional layer of protection against scratches or abrasions during transportation or storage. 3. Implement proper storage and handling techniques: Store aluminum sheets in a clean and dry environment, away from any abrasive materials or surfaces. When moving or handling the sheets, ensure that they are lifted or supported evenly to avoid any bending or distortion that may lead to surface marring. Using appropriate lifting equipment, such as suction cups or clamps, can help distribute the weight evenly and minimize the risk of damage. 4. Clean the surface regularly: Regularly clean the aluminum sheets using a mild detergent or aluminum-specific cleaning solution. This will help remove any dirt, grime, or other substances that could potentially cause surface marring. Be sure to use soft, non-abrasive cleaning tools such as microfiber cloths or sponges to avoid scratching the surface. 5. Implement quality control measures: Establishing quality control measures during the handling process can help identify any potential sources of surface marring. Regular inspections should be conducted to check for any signs of damage or defects. Implementing proper training for employees involved in the handling process can also help minimize the risk of surface marring. By following these preventive measures, you can significantly reduce the chances of surface marring on aluminum sheets during handling, ensuring their pristine condition and quality.

- Q: Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q: Can aluminum sheet be used for aerospace structural components?

- Yes, aluminum sheet can be used for aerospace structural components. Aluminum is commonly used in the aerospace industry due to its desirable properties such as low density, high strength-to-weight ratio, and excellent corrosion resistance, making it suitable for various structural applications in aircraft and spacecraft.

- Q: Can aluminum sheets be used for chemical pumps?

- Yes, aluminum sheets can be used for chemical pumps in certain applications. Aluminum is a lightweight and corrosion-resistant material, making it suitable for handling various chemicals. However, it is important to consider the specific chemical being pumped and its compatibility with aluminum. Certain aggressive or highly corrosive chemicals may react with aluminum and cause damage or contamination. In such cases, alternative materials like stainless steel or plastic may be more suitable. Additionally, the design and construction of the pump should also be taken into account to ensure proper sealing and protection against leaks or spills. It is recommended to consult with a chemical engineer or an expert in the field to determine the compatibility and feasibility of using aluminum sheets for chemical pumps in a specific application.

- Q: How does the surface treatment of aluminum sheet affect its appearance?

- The appearance of aluminum sheet is greatly influenced by its surface treatment. Natural aluminum has a shiny and reflective surface, which can be improved or modified through different surface treatments. One popular surface treatment for aluminum sheet is anodizing, which involves the creation of a protective oxide layer on the surface through an electrochemical process. This treatment offers a wide range of colors and finishes, ranging from vibrant and opaque to translucent and metallic. Anodized aluminum sheets have a sleek and modern look, making them commonly used in architectural and decorative applications. Another option for surface treatment is painting or powder coating. These processes involve applying a layer of paint or powder onto the surface of the aluminum sheet. This treatment allows for customization in terms of color, texture, and finish. Painted or powder-coated aluminum sheets can have a smooth and glossy appearance or a textured and matte finish, depending on the desired outcome. This treatment is frequently utilized in industries like automotive, aerospace, and construction, where aesthetics and durability are important. Additionally, aluminum sheets can undergo mechanical surface treatments like brushing or polishing. Brushing involves creating parallel lines on the sheet's surface using abrasive pads, resulting in a brushed or satin finish. This treatment gives aluminum sheets a contemporary and industrial look. On the other hand, polishing involves buffing the surface to a high gloss and mirror-like finish. This treatment is often used for decorative purposes, such as in the production of jewelry or household items. In conclusion, the surface treatment of aluminum sheet plays a crucial role in determining its appearance. Whether it is anodizing, painting, powder coating, brushing, or polishing, each treatment offers a distinct visual effect that can enhance the aesthetic appeal of the aluminum sheet for specific applications and industries.

- Q: The question asks if it is possible to recycle used aluminum foil to create new aluminum sheets.

- <p>Yes, recycled aluminum foil can be used to make new aluminum sheets. The process involves collecting and sorting the foil, which is then cleaned and melted down. The molten aluminum is poured into molds or rolled into sheets, creating new aluminum products. This recycling method is not only environmentally friendly but also economically viable as it saves energy compared to producing aluminum from raw materials.</p>

- Q: I have a problem when machining aluminium in my machine shop. There are times when the machines aluminium surface turns yellowish (somtimes brown). I do not know what is the main cause of the problem. Is it due to the coolant used?

- Aluminum oxides may appear in different colors depending on hydration states and other variables. Look in a CRC Handbook of Chemistry Physics if available for aluminum compounds and their colors. The colors that you see may also have as much to do with the surface finish as the color of the material on the surface. A microscopically rough surface will appear dark next to a polished surface due to light scattering. I will agree with Ling in principle, but not on details. EDS detection limits on homogeneous samples can be better than 0.1%, although not so good for elements at the light end of the detection range. Current detectors can detect chlorine (a common culprit for aluminum discoloration) at about 0.1%. Your problem with detection and one that Ling has addressed previously may be that a thin film of contamination would not be easily detected by EDS. As Ling suggests, SIMS is a good technique for detecting thin films and low concentrations. The problem with SIMS in this case may be that the detection limits are too good and the technique cannot be quantified. SIMS would detect 2 ppm of chloride and you couldn't tell for sure whether it was 2 ppm, which is probably not an issue here, or 2000 ppm, which would be significant. I would suggest x-ray photoelectron spectroscopy (ESCA or XPS) as an alternative for further study. The technique will analyze thin films (20 A) and detection limits are good enough (about 0.1%). In addition, XPS will give you information about the compounds present, e.g. whether the oxygen is aluminum oxide, aluminum hydroxide, etc. Good Luck.

- Q: What is aluminum curtain wall.

- Shell nosing edge sealing cap

- Q: I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- Your 30-35 lb draw bow is slightly underpowered for hunting. Some states regulate the draw weight to around 50 lbs. So that your arrow does damage when it hits. I would recommend a compound bow as they are easier to draw and the power is there. tTe power will affect the arrow as they bend pretty good when released. But all arrows do that.even the glass and wooden arrows. If there is a flaw in the arrow throw it away!!

Send your message to us

Quarter Inch Aluminum Sheets for Solar Reflector Reflective Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords