1100-H14 Aluminum Sheets 1/16 Thick and Aluminum Slabs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

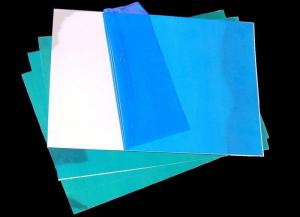

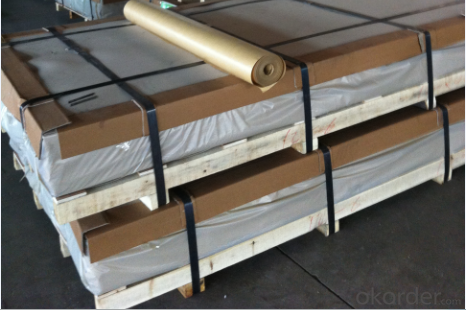

3. Image

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

- Q: Can aluminum sheet be used for heat exchangers?

- Indeed, aluminum sheet can be effectively utilized in heat exchangers. The utilization of aluminum as a material for heat exchangers is widespread owing to its remarkable thermal conductivity, lightweight nature, and resistance to corrosion. The remarkable thermal conductivity of aluminum facilitates the efficient transfer of heat between fluids, rendering it suitable for a multitude of heat exchange applications. Furthermore, aluminum is obtainable in diverse alloys and thicknesses, granting adaptability in design and customization to cater to specific heat exchanger prerequisites. On the whole, aluminum sheet emerges as a favored option for heat exchangers in industries encompassing automotive, HVAC, and aerospace.

- Q: For a high school Chemistry course I made soap for a project. Before doing this, thank god, i learned that one should never use an aluminum container to mix the lye (NaOH) and water. Now, I need to know why. I know it eats away at the container but i can't figure out why. It goes against everything I've learned so far. At first i thought it was because Aluminum was, for some strange reason :o, more reactive than Sodium therefore replacing it in the reaction but that turned out not to be true. Does anyone have an idea of why? Thanks

- Under normal circumstances, aluminum does not react with water, as an impermeable protective layer composed of aluminum hydroxide either forms within seconds or is already in place. With the addition of sodium hydroxide, the formation of a protective layer is prevented. With the production of aluminates [ Al(OH)4 ]-, the amphoteric (capable of acting as either an acid or a base) aluminum hydroxide Al(OH)3 goes in solution: 2 Al + 6 H2O -- 2 Al(OH)3 + 3 H2 Al(OH)3 + NaOH -- Na+ + [ Al(OH)4 ]- A layer of aluminum oxide previously formed by passive corrosion is dissolved by the addition of sodium hydroxide. For this reason, the reaction takes place at the beginning relatively slowly: Al2O3 + 2 NaOH + 3 H2O -- 2 Na+ + 2 [ Al(OH)4 ]- The aluminum completely dissolves and the water acts here too as an acid (for an analog, see Experiment 4.4.1). This reaction is used in drain cleaners. They are mostly made out of strong alkalis, to which alumunim or zinc has been added. The alkalis break down organic residues chemically. In addition, the formation of hydrogen leads to a bubbling effect which adds an additional mechanical cleaning mechanism. The big problem here is the formation of hydrogen gas (as well as some heat). The hydrogen gas is flammable, and if it's in a closed container, will explode

- Q: Can aluminum sheets be used in the automotive industry?

- Aluminum sheets indeed find application in the automotive sector. Being a lightweight and sturdy material, aluminum offers several advantages when it comes to manufacturing automobiles. Car bodies, hoods, doors, and other structural components are commonly produced using aluminum. This helps in reducing the weight of the vehicle, resulting in improved fuel efficiency and enhanced performance. Furthermore, aluminum exhibits remarkable resistance to corrosion, making it ideal for vehicles that face harsh weather conditions. Moreover, aluminum sheets are easily formed, welded, and joined, which adds to their versatility and suitability for various automotive purposes. Consequently, the automotive industry widely embraces the utilization of aluminum sheets due to their numerous benefits.

- Q: Which kind of glue can bond two pieces of aluminum sheets?

- glass sealant

- Q: Can aluminum sheet be used for packaging applications?

- Yes, aluminum sheet can be used for packaging applications. It is a widely used material in the packaging industry due to its excellent properties such as lightweight, durability, and resistance to corrosion. Aluminum sheets are commonly used for packaging food, beverages, pharmaceuticals, and various consumer products.

- Q: a 1 kg block of aluminum and a 1 kg block of lead are immersed in water, Both sink, but which experienced the greater buoyant force? Why?

- 1 kg of Aluminum will require more volume to occupy since it is lighter than lead. Lead has more density to Aluminum.So, when immersed in water Aluminum will displace more volume of water than lead. The buoyant force is equal to the Mass of water thus dispalced . Thus we can say Aluminum will experience more buoyant force.

- Q: Can aluminum sheet be used for automotive body panels?

- Yes, aluminum sheet can be used for automotive body panels. In fact, aluminum is becoming increasingly popular in the automotive industry for its numerous advantages. Firstly, aluminum is lighter than steel, which helps to improve fuel efficiency and overall vehicle performance. Additionally, aluminum is highly corrosion-resistant, making it a durable choice for automotive body panels that are exposed to the elements. Aluminum also has excellent formability and can be easily shaped into complex designs, allowing for greater design flexibility in vehicle manufacturing. Furthermore, aluminum offers superior crash absorption capabilities, enhancing the safety of vehicles. However, it's important to note that while aluminum is a viable option for automotive body panels, it may require specialized equipment and techniques for welding and repair.

- Q: Can aluminum sheets be anodized?

- Yes, aluminum sheets can be anodized. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This layer enhances the metal's corrosion resistance, durability, and appearance. Anodizing is commonly used in various industries such as automotive, aerospace, and construction to provide a protective coating and improve the aesthetics of aluminum sheets. The process involves immersing the aluminum sheet in an acid electrolyte solution and passing an electric current through it, causing oxygen ions to bond with the aluminum atoms and form the oxide layer. This layer can be further enhanced with the addition of dyes or pigments to create different colors and finishes. Overall, anodizing is a versatile and effective method for treating aluminum sheets.

- Q: What is the typical thermal expansion coefficient of aluminum sheets?

- Aluminum sheets generally possess a thermal expansion coefficient of approximately 23.1 x 10^-6 per degree Celsius. Consequently, with each degree Celsius rise in temperature, the length of an aluminum sheet will expand by roughly 23.1 millionths of its initial length. However, it should be acknowledged that this figure might slightly differ based on the particular alloy and processing circumstances of the aluminum sheet.

- Q: What is the density of the 1100 aluminum plate?

- 1100 aluminum plate is generally used in utensils, heat sink, caps, printing plates, building materials, heat exchanger components, but also can be used as deep stamping products. It is widely used in various fields ranging from cooking utensils to industrial equipment.

Send your message to us

1100-H14 Aluminum Sheets 1/16 Thick and Aluminum Slabs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords