T4 T6 Alloy Thickness Aluminum Plate 6063

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of T4 T6 Alloy Thickness Aluminum Plate 6063 Description:

6000 series aluminum alloy is a common aluminum alloy series, the main alloy elements are magnesium, the content of magnesium is 3-5%.It's non-Heat treatable aluminum alloy with good corrosion resistance, good machinability, good electric arc welding performance,beautiful surface after anodic treatment.Commonly used in aviation,shipping field,also extensive used in the conventional industry,such as cars,planes,welding pieces,Metro and light rail,need strict fireproof pressure vessel,such as liquid tankers,refrigerated trucks, refrigerated container,refrigeration equipment,television tower,drilling equipment,transportation equipment,missile parts,armor,etc.

2.Main Features of T4 T6 Alloy Thickness Aluminum Plate 6063:

PVC Protect Film

Waterproof paper

High Quality

Competitive Price

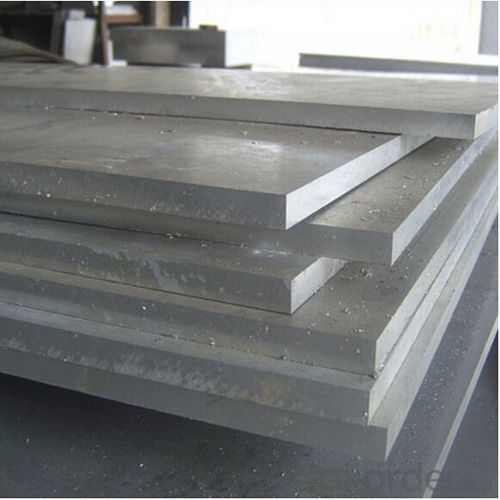

3. T4 T6 Alloy Thickness Aluminum Plate 6063 Images:

4. T4 T6 Alloy Thickness Aluminum Plate 6063 Specification:

Alloy NO. | Thickness | width | length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC |

1220*2440mm(4×8ft) 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | CC | |

6061 6063 | 5-150mm | 800--2200mm | 1000--10000mm | CC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | CC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

20 FT capacity: | About 20 tons | ||||

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects,auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the

details. All the press machines we use is the best quality in China Yangli brand. The

press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with

customer. Our professional mechanical enginners from Austria will design the mould

according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we

can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and

cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you

offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut,

which makes the mould more accurate and precise. Important materials likestainless steel

parts we make in Austria. We also recut after heat treatment, which most of makers do not

take this process.

- Q: What characteristics distinguish pure aluminum from its alloyed forms?

- <p>Pure aluminum is a soft, lightweight, and highly malleable metal with good electrical and thermal conductivity. It is often used for its corrosion resistance and is relatively inexpensive. Aluminum alloys, on the other hand, are made by combining aluminum with other elements like copper, magnesium, silicon, or zinc to enhance its properties. These alloys are stronger, more durable, and can be tailored for specific applications, such as in aerospace, automotive, or construction. They offer improved strength-to-weight ratios, better resistance to heat and wear, and can be anodized for enhanced surface properties. While pure aluminum is more ductile and easier to weld, aluminum alloys provide greater versatility in terms of mechanical properties and performance.</p>

- Q: Is it possible to utilize recycled aluminum in the production of new products more efficiently than current methods?

- <p>Yes, recycled aluminum can be used more effectively in new products than before. Advances in recycling technology have made it easier to purify and refine aluminum from various sources, including post-consumer waste. This not only conserves natural resources but also reduces energy consumption compared to mining and processing raw bauxite. Additionally, the circular economy approach promotes the design of products that are easier to disassemble and recycle, further enhancing the efficiency of using recycled aluminum in new products.</p>

- Q: Is aluminum a suitable material for use in the electronics manufacturing industry?

- <p>Yes, aluminum is widely used in electronics manufacturing due to its excellent electrical conductivity, lightweight nature, and resistance to corrosion. It is commonly used in various electronic components such as heat sinks, capacitors, and wiring. Aluminum's malleability also allows it to be easily shaped into different forms, making it versatile for manufacturing purposes. Additionally, it is cost-effective and abundant, which further contributes to its popularity in the electronics industry.</p>

- Q: This question asks about the relationship between the purity of aluminum and its properties, as well as how purity influences its applications.

- <p>The purity of aluminum significantly affects its properties and uses. High-purity aluminum is soft, ductile, and has excellent electrical and thermal conductivity, making it ideal for applications like electrical wiring and heat sinks. However, its low strength limits its structural applications. To enhance its strength, aluminum is often alloyed with elements like copper, magnesium, and silicon, which increase its hardness and strength while maintaining lightness. These alloys are used in various industries, including aerospace, automotive, and construction. The purity also influences corrosion resistance; high-purity aluminum is more resistant to corrosion than its alloyed counterparts. Therefore, the choice of aluminum's purity and alloying depends on the specific requirements of the intended application.</p>

- Q: This question asks for the various applications or purposes of aluminum alloys.

- <p>Aluminum alloys are used in a wide range of applications due to their lightweight, high strength, and corrosion resistance. They are commonly used in the automotive industry for vehicle construction to reduce weight and improve fuel efficiency. In the aerospace industry, they are essential for constructing aircraft and spacecraft. Other applications include construction materials, such as window frames and roofing, and in consumer goods like beverage cans and electronic devices. Aluminum alloys are also utilized in machinery and transportation equipment, sports equipment, and various engineering components where a combination of strength, durability, and low weight is required.</p>

- Q: This question asks for a brief explanation of the process of recycling aluminum.

- <p>Aluminum recycling involves several steps. First, aluminum waste is collected and sorted. It is then cleaned to remove any contaminants. The cleaned aluminum is melted in a furnace at high temperatures, which is an energy-efficient process as aluminum has a lower melting point compared to other metals. The molten aluminum is then poured into molds to form new products. This process is highly sustainable as it saves energy and reduces waste, with recycled aluminum requiring only 5% of the energy needed to produce new aluminum from raw materials. Recycled aluminum maintains its quality, making it an ideal material for continuous recycling.</p>

- Q: This question asks about the method to determine the strength of aluminum alloy, which is a measure of its ability to withstand stress or deformation before breaking.

- <p>The strength of aluminum alloy is calculated through a series of mechanical tests, primarily the tensile test. In this test, a sample of the alloy is subjected to a gradually increasing tensile force until it fractures. The yield strength is noted at the point where the alloy begins to deform plastically, and the ultimate tensile strength (UTS) is recorded at the point of fracture. The strength is expressed in units of stress (e.g., MPa or psi). Additionally, the hardness of the alloy can be measured using tests like the Brinell or Rockwell hardness test. These values, along with other properties like elongation and reduction of area, provide a comprehensive understanding of the alloy's strength and ductility.</p>

- Q: This question asks if there are differences in how long different types of aluminum cookware can last.

- <p>Yes, there are differences in the durability of different types of aluminum cookware. Anodized aluminum cookware is more durable and resistant to scratches and corrosion compared to non-anodized aluminum. Cast aluminum cookware is heavier and more durable than aluminum clad cookware, which is a layer of aluminum bonded to a stainless steel core. The thickness of the aluminum also affects durability, with thicker aluminum being more resistant to warping and lasting longer. Proper care and maintenance also play a significant role in the longevity of aluminum cookware.</p>

- Q: Is aluminum capable of functioning as a catalyst in chemical reactions?

- <p>Aluminum is not typically used as a catalyst in chemical reactions. Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process. Aluminum, being a metal, does not have the properties necessary to act as a catalyst in most reactions. However, it can be used in certain reactions as a reducing agent or in the form of organoaluminum compounds, which may participate in catalytic processes, but these are not common applications.</p>

- Q: Is it possible to utilize aluminum in car manufacturing to enhance fuel efficiency?

- <p>Yes, using aluminum in car manufacturing can contribute to increased fuel efficiency. Aluminum is lighter than traditional steel, which can reduce the overall weight of a vehicle. A lighter car requires less energy to move, which can lead to better fuel economy. Additionally, aluminum has good strength-to-weight ratio, allowing for a strong yet lighter structure. However, it's important to note that while aluminum can enhance fuel efficiency, it also has higher manufacturing costs and may not be as recyclable as steel.</p>

Send your message to us

T4 T6 Alloy Thickness Aluminum Plate 6063

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords