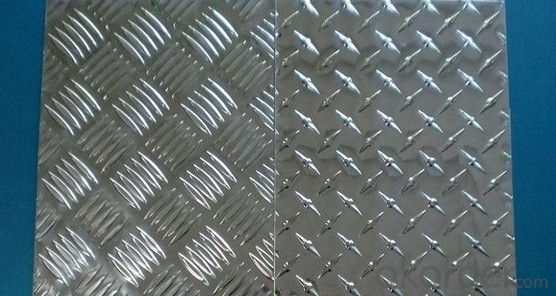

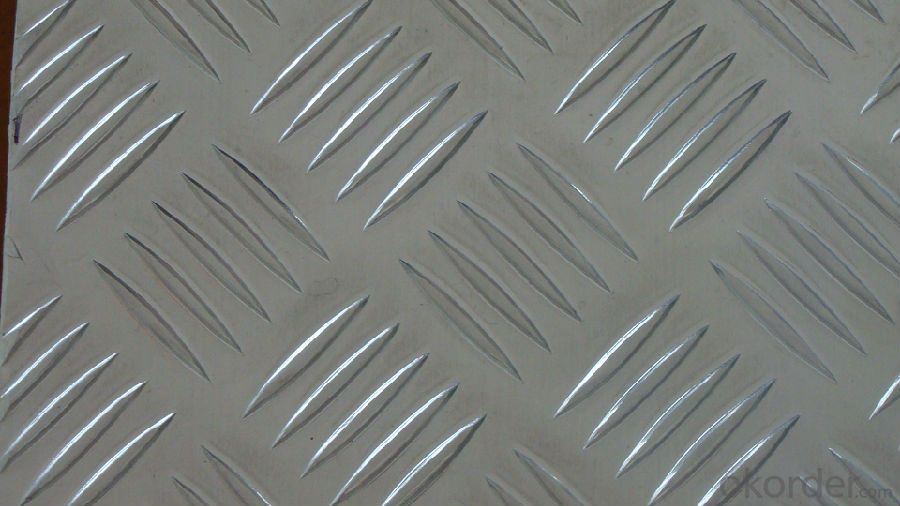

3mm Anti Slip Embossed Aluminum Checker Plate Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

The brilliant shine of Aluminum Diamond Plate adds sparkle, along with durability. As known as: Aluminum Diamond Plate, Aluminum Tread Plate, Tread Bright, Aluminum Floor Plate, this highly reflective, economical product is widely used in decorative, cosmetic and architectural applications. Having good forming, drilling and welding ability, Aluminum Diamond Plate is easy to fabricate and its raised diamond lug pattern provides good slip resistance.

Specifications for anti slip aluminum sheet:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 1.0-10 | 20-2200 | 20-8000 | H12,H22,H14,H16,H18, H24,H26,etc | |

| A3003,A3105,A3004 | 1.0-10 | 20-2200 | 20-8000 | H14,H18,H24,etc | |

| A5052,A5005,A5083, A5754 | 1.0-10 | 20-2200 | 20-8000 | H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 1.0-10 | 20-2200 | 20-8000 | T4,T6,,etc | |

| A8011 | 1.0-10 | 20-2200 | 20-8000 | H12,H22,H14,H16,H18,H24,H26, etc | |

Standards:

ASTM-B209. EN573-1, GB/T3880.1-2006

Quality of material:

totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set

Application :

Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect.

- Q: Are aluminum sheets available in different colors?

- Yes, aluminum sheets are available in different colors. They can be coated or painted in various shades to suit different aesthetic preferences and design requirements. The color options range from traditional metallic finishes like silver and gold to a wide array of vibrant and contemporary colors. The availability of different colors allows aluminum sheets to be used in diverse applications such as architectural cladding, signage, automotive industry, and home décor. Additionally, the color coating or paint on aluminum sheets also provides additional protection against corrosion and enhances their durability.

- Q: What are the different finishes available for aluminum sheets?

- Some different finishes available for aluminum sheets include mill finish, brushed finish, embossed finish, anodized finish, and painted finish.

- Q: What are the potential health risks associated with handling aluminum sheets?

- <p>Working with aluminum sheets can pose certain health concerns, primarily due to inhalation of aluminum dust or fumes. Long-term exposure may lead to respiratory issues and potentially neurological problems. Aluminum dust can cause irritation to the eyes, nose, and throat. In some cases, it may contribute to the development of Alzheimer's disease, although this link is still debated. It's important to follow safety guidelines, such as using proper ventilation and wearing protective gear like masks and gloves, to minimize these risks.</p>

- Q: What are the special coatings or treatments available for enhancing the properties of aluminum sheets?

- <p>Yes, there are several special coatings and treatments that can be applied to aluminum sheets to enhance their properties. These include anodizing, which creates a protective oxide layer, powder coating for a durable and colorful finish, and thermal spraying for improved wear resistance. Other treatments involve chemical conversion coatings, such as chromate conversion, which provides corrosion resistance, and various types of plating like electroplating or hot-dip galvanizing for added strength and protection. These treatments can significantly improve the appearance, durability, and performance of aluminum sheets in various applications.</p>

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation to some extent. While aluminum is not the best material for soundproofing compared to others like rubber or foam, it can still provide some level of sound insulation when used correctly. Aluminum sheets can be installed as a barrier or partition in walls, ceilings, floors, or other surfaces to reduce the transmission of sound waves. However, it is important to note that additional soundproofing materials or techniques might be necessary to achieve optimal results.

- Q: My aluminum storm windows are wasting energy in my home, however, the $7000 estimate to replace them is beyond (well beyond) my comfort zone.I know aluminum is a great conductor of hot and cold. I was considering cleaning the frames, and then coating them with a brush on clear or possibly white liquid rubber to reduce the conductivity. Any idea as to how much benefit I'll realize? Is flammability going to be an issue?I need some solid answers please. Trolls go get your two points elsewhere.Thanks.Your help is much appreciated.

- Coating your existing aluminum windows will help absolutely zero. To be effective, you would need a thermal break between the aluminum and the heated portion of your house. Unless you have aluminum storms applied directly to aluminum windows, you should already have some kind of thermal break. At the end of the day, the aluminum is not really costing you much in terms of energy loss. Adding any kind of coating to the storms does not help because it is not between the aluminum and your heated area. I can't think of a way you could do this anyway. Aluminum is incredibly hard to get a coating to stick to and I have never seen a product that would be suitable for this.

- Q: Are aluminum sheets suitable for signage?

- Signage can greatly benefit from the use of aluminum sheets. This material is known for its versatility and numerous advantages when it comes to signage applications. With its lightweight nature, durability, and resistance to corrosion, aluminum is an excellent choice for both indoor and outdoor signage. Regardless of weather conditions, be it rain, snow, or intense UV exposure, aluminum sheets will not deteriorate or fade. Furthermore, aluminum sheets are easy to work with, providing a wide range of customization options such as embossing, engraving, and digital printing. Not only are they cost-effective, but they also have a long lifespan, ensuring that signage remains in top-notch condition for extended periods. Ultimately, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a preferred choice for signage.

- Q: Is aluminium plate the same as aluminium alloy?

- Oh, No. aluminum contains only aluminum, and there are some other metals besides aluminium.

- Q: What is the typical electrical conductivity of aluminum sheets?

- The typical electrical conductivity of aluminum sheets is around 35-45 million Siemens per meter (MS/m).

- Q: I know 7005 series aluminum is stronger and lighter than 6061series, but how does 7005 compare to 2014 series?

- i okorder

Send your message to us

3mm Anti Slip Embossed Aluminum Checker Plate Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords