Aluminum Ceiling Strips - Light Gauge Aluminium Foils for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Light Gauge Aluminium Foils for Different Usages

Light Gauge Aluminium Foils for Different Usages are widely used in cigarette package, aseptic package, pouches, sachets.

Light Gauge Aluminium Foils for Different Usages meet the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

We have very strict inspection management. Test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Light Gauge Aluminium Foils for Different Usages

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

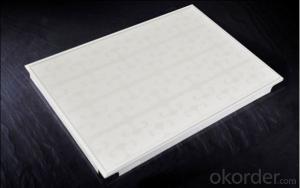

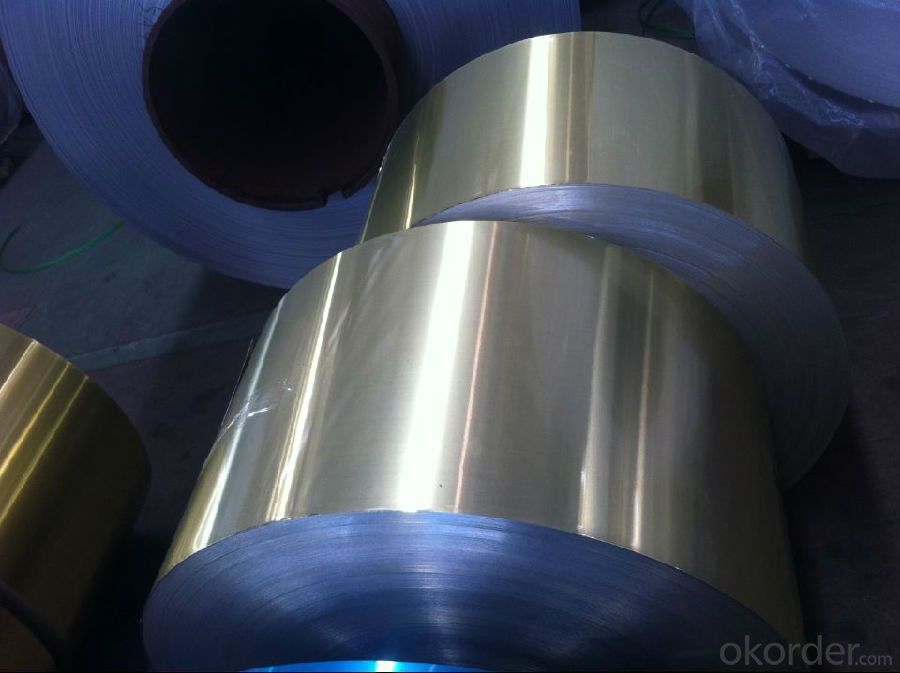

3. Light Gauge Aluminium Foils for Different Usages Images

4.Specification of Light Gauge Aluminium Foils for Different Usages

Alloy | 8011/1235/8079 |

Temper: | O |

Thickness: | 0.006mm-0.009mm (+/-6%) |

Width: | 200mm-1650mm |

Standard: | GB/T3198/ASTM-B209/EN546 |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: This question asks for a comparison of the pros and cons associated with the use of aluminum strips in roofing systems.

- <p>Aluminum strips in roofing offer several advantages such as durability, resistance to corrosion and rust, lightweight nature, and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum strips can be easily recycled, contributing to environmental sustainability. However, there are downsides, including higher initial costs compared to other roofing materials and potential for denting if not properly installed or maintained. Aluminum can also be noisy during rain, and may require more frequent replacement due to its lighter gauge compared to some other materials.</p>

- Q: What types of aluminum strips are known for their durability and longevity?

- <p>Yes, there are several types of aluminum strips known for their durability and longevity. These include 3003-H14, 5052-H32, and 6061-T6 aluminum alloys. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for applications requiring high durability. 5052-H32 offers good strength, corrosion resistance, and weldability, suitable for marine and structural applications. 6061-T6 is valued for its high strength-to-weight ratio and is commonly used in aerospace and automotive industries where long-lasting performance is crucial. Proper surface treatments and coatings can further enhance the durability and longevity of aluminum strips.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a roof.

- <p>To install aluminum strips on your roof, follow these steps: 1. Clean the roof surface to ensure a proper bond. 2. Measure and cut the aluminum strips to the required length. 3. Apply a high-quality adhesive or sealant to the back of the aluminum strips. 4. Position the strips on the roof, ensuring they are aligned and straight. 5. Press firmly to secure the strips in place and allow the adhesive to cure according to the manufacturer's instructions. 6. Check for any gaps or uneven areas and apply additional sealant if necessary. 7. Regularly inspect and maintain the aluminum strips to ensure they remain in good condition. Always follow safety precautions and consider hiring a professional if you are unsure about any steps.</p>

- Q: What constitutes the primary substance of aluminum strips?

- <p>Aluminum strips are primarily made from aluminum, a lightweight and malleable metal known for its high conductivity and resistance to corrosion. They are typically composed of pure aluminum or aluminum alloys, which may include elements such as copper, magnesium, manganese, or silicon to enhance specific properties like strength or durability. These strips are widely used in various industries due to their versatility and the metal's beneficial characteristics.</p>

- Q: This question asks for the steps to attach aluminum strips to a wall or roof surface.

- <p>To install aluminum strips on a wall or roof, first measure and mark the area where you want to install the strips. Ensure the surface is clean and dry. Apply a suitable adhesive or use screws, depending on the type of strip and surface. Align the first strip and press firmly or secure with screws. For subsequent strips, use a spacer if needed to maintain consistent spacing. Check alignment regularly and ensure all strips are level. Seal any gaps with appropriate sealant and finish with a protective coating if required. Always follow the manufacturer's instructions for the specific product you are using.</p>

- Q: What are the benefits of utilizing tailor-made aluminum strips?

- <p>Custom-made aluminum strips offer several advantages, including precise fit and dimensions tailored to specific applications, enhanced durability due to the material's strength and corrosion resistance, and cost-effectiveness as they can be designed to minimize waste. They also allow for unique designs and shapes that standard strips may not offer, providing a competitive edge in industries where aesthetics and functionality are crucial. Additionally, custom aluminum strips can be anodized or coated to meet specific color or finish requirements, enhancing their versatility in various applications.</p>

- Q: What other materials could potentially be used in place of aluminum strips for specific uses?

- <p>Yes, there are alternative materials that can replace aluminum strips in certain applications. These include stainless steel, which offers high strength and corrosion resistance; copper, known for its excellent electrical conductivity; magnesium alloys, which are lightweight and have good thermal conductivity; and titanium, prized for its strength and resistance to corrosion. The choice of material depends on the specific requirements of the application, such as strength, weight, cost, and environmental factors.</p>

- Q: Are aluminum strips suitable for use as interior wall materials?

- <p>Yes, aluminum strips can be used for interior walls. They are known for their durability, resistance to moisture, and ease of installation. Aluminum strips are often used in modern designs for their sleek, contemporary look and can be found in various forms such as aluminum wall panels or as decorative strips. They are low maintenance and do not warp or rot, making them ideal for high-moisture areas like bathrooms and kitchens. However, they may not provide the same insulation or soundproofing as traditional wall materials, so their use may be limited to certain areas or combined with other materials for optimal performance.</p>

- Q: This question asks for the standard cost range of aluminum strip stock, which is a type of metal material.

- <p>The typical price range for aluminum strip stock can vary significantly based on factors such as grade, thickness, width, and market conditions. As of recent market trends, prices can range from approximately $1.50 to $3.00 per pound for common grades like 1100 or 3003. However, for more specialized grades or custom specifications, the cost can be higher, potentially ranging from $2.00 to $5.00 per pound or more. It's important to note that these prices are subject to change due to fluctuations in the global aluminum market and should be verified with a supplier for the most accurate and current pricing.</p>

- Q: Is it possible to utilize recycled aluminum strips for construction purposes?

- <p>Yes, you can use recycled aluminum strips in your construction projects. Recycled aluminum is not only environmentally friendly but also cost-effective. It maintains the same strength and durability as new aluminum, making it suitable for various construction applications such as framing, roofing, and cladding. However, it's crucial to ensure that the recycled aluminum meets the required industry standards and specifications for your project to guarantee safety and performance. Always consult with a professional or engineer to confirm the suitability of recycled aluminum for your specific construction needs.</p>

Send your message to us

Aluminum Ceiling Strips - Light Gauge Aluminium Foils for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords