Aluminum Strips for Sale - AA1XXX Mill Finished Aluminum Strips for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

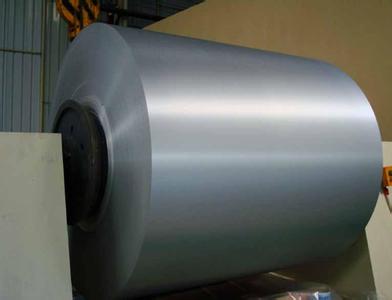

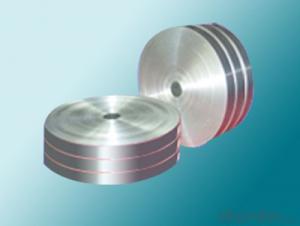

1.Structure of AA1xxx Mill Finished Aluminum Strips Used for Construction

AA1xxx Mill Finished Aluminum Strips Used for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns.

AA1xxx Mill Finished Aluminum Strips Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1xxx Mill Finished Aluminum Strips Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3.AA1xxx Mill Finished Aluminum Strips Used for Construction Images

4.AA1xxx Mill Finished Aluminum Strips Used for Construction Specification

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1xxx Mill Finished Aluminum Strips Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA5xxx Mill-Finished Aluminum Coils Used for Construction.

B.When will you deliver the products?

AA5xxx Mill-Finished Aluminum Coils Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What types of aluminum are known for their high strength and resistance to wear and tear?

- <p>Yes, certain types of aluminum alloys are known for their exceptional strength and resistance to wear and tear. 7075 aluminum, for instance, is one of the strongest aluminum alloys, often used in aerospace and automotive applications due to its high strength-to-weight ratio. Another example is 6061 aluminum, which is commonly used in structural applications because of its good mechanical properties and resistance to corrosion. These alloys achieve their strength through the addition of elements like copper, magnesium, and zinc, which enhance their properties for specific industrial uses.</p>

- Q: What specific conditions or considerations are needed when installing aluminum strips for flooring in cold weather conditions?

- <p>In cold climates, using aluminum strips for flooring requires considering thermal expansion and contraction due to temperature changes. It's crucial to allow for adequate expansion gaps to prevent buckling or warping. Additionally, it's important to use aluminum alloys with good low-temperature toughness to prevent brittleness. Proper insulation and a stable subfloor temperature are also necessary to maintain the integrity of the flooring. Always consult with a professional or manufacturer for specific recommendations tailored to the climate and project requirements.</p>

- Q: Inquiring about the durability of aluminum strips.

- <p>Aluminum strips are known for their durability. They are resistant to corrosion and weathering, making them suitable for long-term use in various environments. Their strength and light weight also contribute to their durability, allowing them to withstand significant stress without breaking. However, their longevity can be affected by factors such as the quality of the aluminum, the manufacturing process, and the specific conditions they are exposed to. Proper maintenance and handling can further enhance their durability.</p>

- Q: This question asks for an explanation of the various kinds of aluminum strips that exist, which could include their properties, uses, and any other distinguishing features.

- <p>Aluminum strips come in various types, differentiated by their alloy composition, thickness, width, and temper. Common types include 1000 series strips, which are 99% pure aluminum, known for their high thermal and electrical conductivity. 3000 series strips, like 3003 alloy, offer good formability and are used in cooking utensils and chemical equipment. 5000 series strips, such as 5052, are known for their strength and are used in marine applications and aircraft structures. 6000 series strips, like 6061, are heat-treatable and used in construction and automotive parts. Each type has specific properties that make them suitable for different applications, from lightweight structures to high-strength components.</p>

- Q: Is it possible to use aluminum strips as a material for roofing purposes?

- <p>Yes, aluminum strips can be used for roofing. They are known for their durability, corrosion resistance, and lightweight properties, making them a popular choice for metal roofing. Aluminum roofing strips are low maintenance, energy-efficient, and can be recycled, offering environmental benefits. They are also resistant to harsh weather conditions and can last for several decades with proper installation and care.</p>

- Q: Is it possible to utilize aluminum strips instead of conventional siding materials in areas with high temperatures?

- <p>Yes, aluminum strips can be used to replace traditional siding materials in hot climates. Aluminum is a lightweight, durable, and corrosion-resistant material that can withstand high temperatures. It reflects heat, reducing the amount of heat absorbed by the building, making it a suitable choice for hot climates. Additionally, aluminum siding is low maintenance and can be easily painted or finished to match the desired aesthetic. However, it's important to consider factors such as insulation properties and potential for condensation, as aluminum may not insulate as well as some other materials.</p>

- Q: How does the excavator aluminum belt turn in place?

- When the mechanical steering, separate driving force on the side of the track of unilateral, separation power can not overcome the ground friction due to the relative motion in a static state; and the other side of the track with power in motion, its trajectory is a circle, this is equivalent to us so we use your compasses to draw a circle; see mechanical steering.

- Q: What's the difference between aluminum strip and aluminum alloy?

- The most common aluminum alloy is magnesium aluminum alloy, widely used in doors and windows frame. Light quality, high hardness, high strength and beautiful appearance. Of course, the magnesium aluminum alloy is also very many kinds, the use is more widespread. The aluminum is soft, low strength and easy to corrode. Aluminum cookers also cause excessive aluminum poisoning

- Q: Is it possible to utilize aluminum strips in environments with high temperatures?

- <p>Aluminum strips can be used in high-temperature environments, but their performance and longevity depend on the specific conditions and the alloy type. Pure aluminum has a melting point of 660掳C (1220掳F), but aluminum alloys can be designed to withstand higher temperatures. For instance, some aluminum alloys are used in aerospace and automotive applications where they experience high temperatures. However, prolonged exposure to high temperatures can lead to material degradation, so it's crucial to select the right alloy and consider the temperature limits specified by the manufacturer for the intended application.</p>

- Q: What are the elements or materials that make up aluminum strips?

- <p>Aluminum strips are primarily composed of aluminum, which is a lightweight and malleable metal with the chemical symbol Al and atomic number 13. They may also contain trace amounts of other elements such as copper, magnesium, manganese, silicon, and zinc, depending on the specific alloy. These additional elements are often added to enhance properties such as strength, corrosion resistance, or workability. Pure aluminum is soft and not commonly used for strips; instead, aluminum alloys are preferred for their improved characteristics.</p>

Send your message to us

Aluminum Strips for Sale - AA1XXX Mill Finished Aluminum Strips for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords