Aluminum Strips Menards for Decoration Using

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Some about aluminum?

Aluminium is theoretically 100% recyclable without any loss of its natural qualities. According to the International Resource Panel's Metal Stocks in Society report, the global per capita stock of aluminium in use in society (i.e. in cars, buildings, electronics etc.) is 80 kg (180 lb). Much of this is in more-developed countries (350–500 kg (770–1,100 lb) per capita) rather than less-developed countries (35 kg (77 lb) per capita). Knowing the per capita stocks and their approximate lifespans is important for planning recycling.

Recovery of the metal via recycling has become an important use of the aluminium industry. Recycling was a low-profile activity until the late 1960s, when the growing use of aluminium beverage cans brought it to the public awareness.

2.Specification and Application

ALLOY: AA1*** (AA1050,AA1060,AA1070,AA1100 etc.)

AA3*** (AA3003,AA3004,AA3005,AA3105 etc.)

AA5*** (AA5052,AA5083,AA5754 etc)

AA8*** (AA8011,AA8006 etc)

TEMPER: H14,H16,H18,H22,H24,H26,H32,O/F

THICKNESS: 0.2mm-100mm

WIDTH: 30mm-1700mm

STANDARD: GB/T 3880-2006

Special specification is available on customer's requirement

Standard: GB/T3198/ASTM-B209/EN546

3.Why you choose us?

Our company promise the best quality, best service and best price.Welcome you to visit our factory!

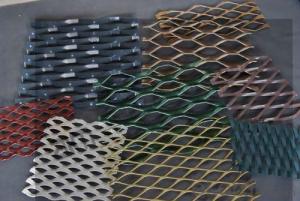

4.Pictures

5.FAQ:

1)what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

2)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3)Can we supply samples?

Yes, we can!

4)What can you do if you have other quastions?

You can contact us freely at any time!

2)How about our payment term?

LC and TT and other.

3)Which country can we supply?

All around the world!

lubricant container foil

Appication: For different food container, such as dishes, plates, trays, etc

Alloy: 8011/3003

Temper:O/H22/H24

Thickness& Tolerance: 0.05mm-0.20m(±8%)

Width& tolerance: 200mm-1650mm(±1mm)

Lubricant: Lubricant

Standard: GB/T3198/ASTM-B209/EN546

- Q: Is it possible to utilize aluminum strips for constructing outdoor decking or railings?

- <p>Yes, aluminum strips can be used for outdoor decking or railings. They are known for their corrosion resistance, low maintenance, and durability, making them suitable for outdoor applications. Aluminum is lightweight, strong, and can withstand various weather conditions without rusting. However, it's essential to ensure that the aluminum is of high quality and properly treated to maintain its performance over time. Additionally, it's crucial to follow proper installation practices to ensure safety and longevity.</p>

- Q: This question asks about the various forms or configurations that aluminum strips can take in terms of their shape.

- <p>Aluminum strips are available in various shapes to meet different industrial and manufacturing needs. Common shapes include rectangular, square, and circular strips. Rectangular strips are the most common and can be found in various thicknesses and widths. Square strips are less common but still used in specific applications. Circular strips, also known as aluminum wire, are used in electrical applications and other areas requiring a round cross-section. Other shapes like triangular, hexagonal, or custom profiles can also be produced but are less standard and typically require specialized manufacturing processes.</p>

- Q: Why is the president of aluminum strip mildew, will affect the performance of the transformer?

- Aluminum with long mildew is actually aluminum is oxidized, the conductivity of alumina is lower than aluminum, so the resistance increases, resulting in increased contact surface heating, may endanger the insulation of the transformer will reduce the performance.

- Q: Which is better, an aluminum belt excavator or a tire excavator?

- Crawler for complex terrain, strong applicability and maneuverability is weak; tire flexibility, can be a wide range of mobile operations, operations such as cement or asphalt pavement crawler excavator can not enter, but only suitable for light duty work

- Q: Is it possible to use aluminum strips to construct a solar reflector system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a solar reflector system for your home or business. Aluminum is a reflective material and can be shaped into strips to reflect sunlight. These strips can be arranged in a way to direct sunlight towards solar panels or into specific areas to reduce the need for artificial lighting and heating. However, for optimal efficiency, you should consider the angle of reflection, the positioning of the strips relative to the sun's path, and the overall design of the system. Consulting with a professional in solar technology can help ensure that your solar reflector system is effective and safe.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum strips.

- <p>Aluminum strips offer several advantages, including high strength-to-weight ratio, making them lightweight yet durable. They are also corrosion-resistant, which is beneficial in various environments. Aluminum is a good conductor of heat and electricity, which is useful in applications requiring thermal or electrical conductivity. Additionally, aluminum is cost-effective and widely available. Disadvantages include its lower strength compared to some other metals, making it less suitable for heavy-duty applications. It can also be prone to denting and is not as easily repaired as some materials. Lastly, while it's recyclable, the recycling process can be energy-intensive.</p>

- Q: This question asks for an overview of the steps involved in the manufacturing of aluminum components used in vehicles.

- <p>The production process of automotive aluminum parts typically involves several key steps: material selection, design, casting or forging, machining, heat treatment, surface treatment, and quality control. Aluminum is chosen for its lightweight and high strength properties. The design phase involves creating detailed plans for the part. Casting or forging shapes the aluminum into rough forms. Machining refines these forms to precise specifications. Heat treatment enhances strength and durability. Surface treatments protect against corrosion and wear. Finally, quality control ensures each part meets industry standards before it is used in vehicles.</p>

- Q: What types of aluminum strips are more appropriate for commercial use?

- <p>Yes, there are specific types of aluminum strips that are more suitable for commercial applications. These include 1100 series aluminum strips, known for their high purity and excellent formability, making them ideal for general commercial purposes. 3003 series aluminum strips are also popular due to their enhanced corrosion resistance and formability, suitable for applications requiring moderate strength and good workability. Additionally, 5052 series aluminum strips offer good corrosion resistance and weldability, making them suitable for applications in the marine and transportation industries. The choice of aluminum strip depends on the specific requirements of the commercial application, such as strength, corrosion resistance, and formability.</p>

- Q: What are the certifications or standards that apply to aluminum strips?

- <p>Yes, there are several certifications and standards for aluminum strips. These include ASTM B209, which specifies requirements for aluminum and aluminum alloy sheet and plate, and EN 573, which covers the chemical composition and mechanical properties of aluminum and aluminum alloys. Additionally, there are ISO standards such as ISO 6361 and ISO 6892 that define the requirements for aluminum and aluminum alloys in terms of mechanical properties and chemical composition. These standards ensure the quality and consistency of aluminum strips used in various industries.</p>

- Q: Describe the steps involved in the manufacturing process of aluminum strips.

- <p>The process for manufacturing aluminum strips involves several key steps. Initially, aluminum ingots are melted in a furnace, often using a direct current furnace for better control over the melting process. The molten aluminum is then poured into molds to create a cast billet. This billet is then heated and passed through a series of rolling mills to reduce its thickness and achieve the desired strip dimensions. During rolling, the aluminum is continuously cooled to control its temperature and maintain its mechanical properties. After rolling, the aluminum strip may undergo additional processes such as annealing to improve ductility or coating to provide a protective layer. Finally, the strip is cut to length, inspected for quality, and packaged for distribution.</p>

Send your message to us

Aluminum Strips Menards for Decoration Using

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords