1/4 Inch AA1XXX Aluminum Strips Mill-Finished for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1xxx Aluminum Strips Mill-Finished Used for Construction Description

AA1xxx Aluminum Strips Mill-Finished Used for Construction is cut from aluminum coils 1xxx. The aluminum content of Aluminum Strips 1XXX Mill Finished is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA1xxx Aluminum Strips Mill-Finished Used for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1xxx Aluminum Strips Mill-Finished Used for Construction

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

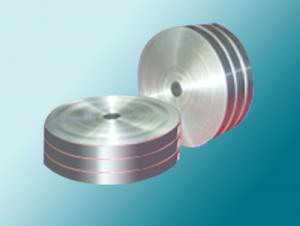

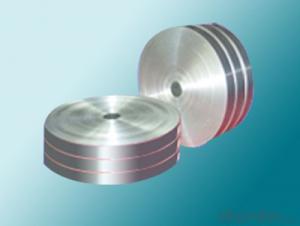

3.AA1xxx Aluminum Strips Mill-Finished Used for Construction Images

4.AA1xxx Aluminum Strips Mill-Finished Used for Construction Specification

| Alloy | AA1xxx (AA1050, AA1060, AA1070,AA1100 etc. |

| Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of AA1xxx Aluminum Strips Mill-Finished Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: This question asks for guidance on selecting a dependable supplier for aluminum strips, implying the need for criteria to evaluate supplier reliability.

- <p>To choose a reliable supplier of aluminum strips, consider the following: Check their reputation and industry experience. Ensure they have certifications for quality management systems like ISO 9001. Look at their product quality, consistency, and adherence to industry standards. Evaluate their delivery times and reliability. Assess their customer service and after-sales support. Investigate their financial stability to avoid potential risks. Request references from current or past clients to gauge their performance. Finally, consider the supplier's ability to scale up production to meet your growing needs.</p>

- Q: This question asks about the strength or durability of aluminum strips, which are commonly used in various industries.

- <p>Aluminum strips are known for their strength-to-weight ratio, offering a high level of strength relative to their weight. They can withstand significant tensile loads and are highly resistant to corrosion. The exact strength of an aluminum strip depends on its alloy composition, thickness, and temper. For instance, 6061-T6 aluminum, a common alloy, has a yield strength of approximately 276 MPa (40,000 psi) and a tensile strength of around 310 MPa (45,000 psi). Aluminum strips are also ductile, allowing them to be bent and shaped without breaking. Their strength makes them suitable for applications in construction, transportation, and aerospace industries.</p>

- Q: Is it possible to utilize aluminum strips for creating decorative patterns or designs on the exterior of buildings?

- <p>Yes, aluminum strips can be used to create patterns or designs on building exteriors. They are lightweight, durable, and resistant to corrosion, making them ideal for outdoor applications. Aluminum strips can be cut, bent, and shaped into various forms to create intricate designs and patterns. They can also be anodized or painted to achieve different colors and finishes, enhancing the aesthetic appeal of the building's exterior.</p>

- Q: Aluminum tape spraying process, please?

- (1) surface pretreatment, mainly degreasing and rust removing, the method is the same as that of liquid paint(2) putty. According to the degree of workpiece defects, coated with conductive putty, after drying with sandpaper grinding smooth, you can carry out the next process(3) protection (also known as covering). If some parts of the workpiece do not require coating, it can be covered with protective glue before preheating so as to avoid spraying paint

- Q: Is it possible to use aluminum strips to construct a solar reflector system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a solar reflector system for your home or business. Aluminum is a reflective material and can be shaped into strips to reflect sunlight. These strips can be arranged in a way to direct sunlight towards solar panels or into specific areas to reduce the need for artificial lighting and heating. However, for optimal efficiency, you should consider the angle of reflection, the positioning of the strips relative to the sun's path, and the overall design of the system. Consulting with a professional in solar technology can help ensure that your solar reflector system is effective and safe.</p>

- Q: Is it possible to apply paint to aluminum strips once they have been installed?

- <p>Yes, aluminum strips can be painted after installation. However, it is essential to prepare the surface properly. This includes cleaning the aluminum to remove any dirt or grease, then lightly sanding it to create a better surface for the paint to adhere to. It is also recommended to use a primer specifically designed for metal surfaces to enhance the paint's durability and adhesion. After priming, the aluminum strips can be painted with a suitable paint, such as a high-quality acrylic or enamel paint, following the manufacturer's instructions for application and drying times.</p>

- Q: This question asks for guidance on ensuring the correct installation and ongoing maintenance of an aluminum strip.

- <p>To ensure your aluminum strip is properly installed and maintained, follow these steps: First, ensure the surface where the strip will be installed is clean and free of debris. Use a high-quality adhesive that is compatible with aluminum for installation. Apply the adhesive evenly and press the strip firmly into place. Check for any gaps or misalignments and correct them immediately. For maintenance, regularly clean the strip to prevent dirt buildup. Avoid using harsh chemicals that could damage the aluminum. Inspect the strip periodically for signs of wear or damage and repair or replace as necessary. Proper installation and regular maintenance will extend the life of your aluminum strip and ensure its functionality.</p>

- Q: This question asks for a step-by-step guide on how to install aluminum strip siding on a building.

- <p>To install aluminum strip siding, first, prepare the surface by cleaning and leveling the exterior walls. Measure and cut the siding strips to the required lengths. Apply construction adhesive to the back of the strips and press them onto the wall, starting from the bottom and working upwards. Use a nail gun to secure the strips, spacing nails evenly along the length. Overlap the strips by about 1/2 inch and trim the top edge to fit the eave or soffit. Apply caulk to seal any gaps and finish with a touch-up paint if necessary. Always follow the manufacturer's instructions for specific siding materials.</p>

- Q: What's the difference between aluminum strip and aluminum alloy?

- Aluminium strip is pure metal and is pureAluminum alloy is an alloy and a mixture

- Q: This question asks for methods to identify if the roof material is aluminum strips.

- <p>To determine if your roof is made of aluminum strips, you can look for the following characteristics: 1) The roof has a shiny, metallic appearance, which is typical of aluminum. 2) The strips are lightweight and flexible, making them easy to handle. 3) They are often interlocking, which is a common feature of aluminum strip roofing. 4) Check for any manufacturer's markings or labels that might indicate the material. If you're unsure, a professional roof inspector can help confirm the material by examining the roof closely or taking a small sample for testing.</p>

Send your message to us

1/4 Inch AA1XXX Aluminum Strips Mill-Finished for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords