Aluminum Flat Strips for Pharmaceutical Bottle Cap

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

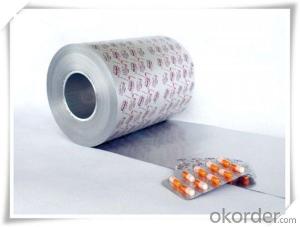

1.Description

Aluminum strip is widely used in industry, such as packaging & building industry. Because the good anti heat and anti wet specification. it's very good for pharmaceutical bottle caps. Normally it's coated lacquer, coating thickness is around 4~5mic.

2.Specification and Application

Specification

| Alloy | 8011 |

| Temper | H12/ H14/ H16 |

| Process | DC |

| Thickness | 0.17~0.25mm |

| Width | As required |

| Core ID | As required |

Property

| Tensile strength | ≥120Mpa |

| Elongation | ≥2% |

| Tolerance of size | As GB Standard |

3. Advantages

We've been specialized in aluminium for more than ten years, we know this product very well, and we have good finacial support from government. And also flexible payment term and fast delivery.

4. Pictures

5. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your minimum order quantity?

It's 3tons per size.

- Q: Is it possible to join aluminum strips together through welding?

- <p>Yes, aluminum strips can be welded. Welding aluminum requires specific techniques and equipment due to its high thermal conductivity and reactivity. Common methods include gas tungsten arc welding (GTAW), also known as TIG welding, and gas metal arc welding (GMAW), or MIG welding. These processes involve using a filler material and an inert shielding gas to prevent oxidation. Proper preparation, such as cleaning the aluminum surface and controlling the heat input, is crucial for a successful weld.</p>

- Q: This question asks for the duration aluminum strips can last or their service life.

- <p>The lifespan of aluminum strips can vary significantly based on factors such as the environment in which they are used, the quality of the material, and the specific application. In general, if properly maintained and not exposed to harsh conditions, aluminum strips can last for several decades. For instance, in construction, aluminum strips used in framing can have a lifespan of 20 to 40 years. However, in more aggressive environments or with frequent wear and tear, this lifespan can be considerably shorter. It's important to note that aluminum is a recyclable material, and its lifespan can be extended through recycling processes.</p>

- Q: This question asks for the cost of aluminum strip roofing, which is a type of metal roofing material.

- <p>The cost of aluminum strip roofing can vary significantly based on factors such as the quality of the aluminum, the complexity of the installation, and regional pricing. On average, the cost of aluminum strip roofing ranges from $6 to $12 per square foot for the materials alone. This does not include labor costs, which can add another $3 to $10 per square foot. It's important to get quotes from multiple contractors in your area to get an accurate estimate for your specific project. Prices can fluctuate, so it's best to check current market rates for the most up-to-date information.</p>

- Q: What types of aluminum alloys have higher tensile strength compared to others?

- <p>Yes, certain aluminum alloys exhibit superior tensile strength compared to others. For instance, 7075 aluminum alloy, known for its high strength, is often used in aerospace applications. It has a tensile strength of around 524 MPa. Another strong alloy is 2024, which is used in aircraft structures and has a tensile strength of about 425 MPa. These alloys achieve their strength through heat treatment and alloying elements like copper, magnesium, and zinc, which enhance their mechanical properties.</p>

- Q: Can metal roofing materials be reused or recycled after they have been installed and used?

- <p>Yes, metal roofing materials can indeed be recycled after installation. Metal is one of the most recycled materials globally, and its recycling process is both efficient and environmentally friendly. When metal roofing reaches the end of its life, it can be collected, processed, and turned into new metal products, including new roofing materials. This recycling process helps conserve natural resources and reduces waste in landfills. The high recycled content of metal can also contribute to the sustainability and green credentials of construction projects.</p>

- Q: This question asks about the environmental impact of aluminum strips, which are thin pieces of aluminum metal.

- <p>Aluminum strips can have both positive and negative effects on the environment. On the positive side, aluminum is highly recyclable, and using recycled aluminum reduces the need for mining new bauxite, thus conserving natural resources and reducing the environmental impact of mining. However, the production of aluminum, especially from raw materials, is energy-intensive and contributes to greenhouse gas emissions. Additionally, improper disposal of aluminum can lead to pollution, as it does not degrade naturally and can accumulate in landfills. The environmental impact can be mitigated by promoting recycling and responsible disposal practices, as well as by using aluminum more efficiently in products to extend their lifespan and reduce waste.</p>

- Q: This question asks if it's possible to use various types of siding materials on a home's exterior to achieve a desired aesthetic.

- <p>Yes, you can use different types of siding on your home's exterior to match your style. Mixing materials such as vinyl, wood, brick, or stone can create a unique and personalized look. It's important to consider the architectural design and ensure that the materials complement each other in terms of color, texture, and style. Consult with a professional to help you choose the right combination that suits your home and preferences while also considering factors like durability, maintenance, and cost.</p>

- Q: Describe how the weight of an aluminum strip compares to other common roofing materials.

- <p>An aluminum strip is significantly lighter than many other roofing materials. It weighs approximately 1.5 to 2.5 pounds per square foot, depending on the thickness and profile. In contrast, asphalt shingles can weigh between 2.5 to 4.5 pounds per square foot, while concrete tiles can be as heavy as 7 to 10 pounds per square foot. Clay tiles are also heavier, typically ranging from 6 to 8 pounds per square foot. This makes aluminum strips an attractive option for those seeking a lightweight roofing solution.</p>

- Q: Explain the relationship between aluminum strips and aluminum foil, including their similarities and differences.

- <p>Aluminum strips and aluminum foil are both made from the same material, aluminum, but they differ in their form and thickness. Aluminum strips are typically thin, flat pieces of aluminum that are longer and narrower compared to aluminum foil. They are often used in industrial applications, such as in the manufacturing of electrical components or as a conductive material in various devices. Aluminum foil, on the other hand, is much thinner and is commonly used in cooking, food storage, and packaging due to its high barrier properties against air and moisture. While aluminum strips may be thicker and more rigid, aluminum foil is lightweight and flexible, making it suitable for a wide range of consumer and household uses.</p>

- Q: Is it possible to utilize recycled aluminum in the production of new solar panels or reflectors?

- <p>Yes, recycled aluminum can be used to make new solar panels or reflectors. Aluminum is a valuable material in solar panel construction, particularly for framing and mounting structures. It is lightweight, durable, and has good thermal conductivity. Recycling aluminum reduces energy consumption and environmental impact compared to mining and processing new aluminum. Recycled aluminum can be melted down and reformed into new shapes, making it suitable for manufacturing solar panel components. However, the quality of recycled aluminum must meet specific standards to ensure the structural integrity and performance of the solar panels or reflectors.</p>

Send your message to us

Aluminum Flat Strips for Pharmaceutical Bottle Cap

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords