Sheets of 3/4 Thick Continuous Casting Aluminium Coil for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

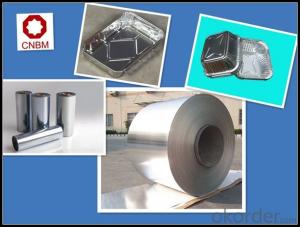

1.Structure of Continuous Casting Aluminium Coil for Building

Continuous Casting Aluminium Coil for Building is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coil for Building

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1500MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How does the thickness of aluminum sheet affect its formability?

- The thickness of an aluminum sheet directly affects its formability. Thinner sheets are generally more flexible and easier to bend or shape, making them more formable. On the other hand, thicker sheets are less malleable and require more force to bend or form, resulting in reduced formability.

- Q: Hi everyone, I have this problem that I'm somewhat confused about. The problem is:An alloy of aluminum and magensium was treated with sodium hydroxide solution, in which only aluminum reacts to give hydrogen gas:2Al + 2NaOH + 6H20 --gt; 2NaAl(OH)4 + 3H2If a sample of alloy weighing 1.118 g gave 0.1068 g of hydrogen, what is the percentage aluminum in the alloy?How do I account for the magnesium and what stoichiometric relationships would I need to set-up? This is very confusing, but I appreciate the slightest of help on this!Thank you.

- Aluminum foil

- Q: Can aluminum sheets be used for heat sinks?

- Yes, aluminum sheets can be used for heat sinks. Aluminum is a popular material for heat sinks due to its high thermal conductivity, lightweight nature, and affordability. It efficiently transfers heat away from electronic components or devices, helping to dissipate and regulate their temperature effectively.

- Q: The only materials i can use is iodine, water, HCl, magnet, and pH paper. How do you identify aluminum with that?

- To start with, are you refering to aluminum as metal, an aluminum compound, or a solution with aluminum present as ions? If it is metaallic aluminum, it won't stick to a magnet, and it will react with HCl, however this isn't sufficient to definately say it is aluminum, it would be better to get a density, melting point, etc.

- Q: Aluminum and oxygen gas react to produce aluminum oxide

- Aluminium oxide is Al2O3, so there are 3 oxygen atoms for every 2 aluminium atoms. Divide 75 by the relative atomic mass of oxygen (15.9994). That is proportional to the number of oxygen atoms. Then divide by 3 and multiply by 2. This gives a number proportional to the number of aluminium atoms. Then multiply this by the relative atomic mass of aluminium (26.981529) to give the mass of aluminium required in grams.

- Q: How to clean the engine oil and kerosene on the surface of aluminum sheet?

- you can buy a bottle of petroleum ether in chemical raw material shop, it will be clean after rubbing, or you can buy solvent oil.

- Q: Can 101 aluminum sheets be anodized in different colors?

- Yes, 101 aluminum sheets can be anodized in different colors. Anodizing is a process that involves creating an oxide layer on the surface of aluminum, which can be dyed to achieve various colors. The number of sheets, in this case 101, does not restrict the ability to anodize them in different colors. Each sheet can be individually anodized and dyed to create a unique and desired color. Anodizing is a versatile process that allows for customization and color variation, making it possible to achieve different shades and hues on each aluminum sheet.

- Q: Are aluminum sheets suitable for insulation purposes?

- Indeed, aluminum sheets prove to be well-suited for insulation endeavors. Aluminum, being a notably reflective substance, possesses the ability to effectively impede the transmission of heat, rendering it a superb selection for insulation purposes. With its low emissivity value, aluminum reflects heat radiation rather than absorbing it, thereby aiding in the preservation of a uniform temperature within a given area and diminishing the necessity for heating or cooling. Moreover, aluminum sheets are characterized by their lightweight nature, straightforward installation process, and resistance to moisture, making them an eminently practical choice for insulation in a plethora of applications, including attics, walls, floors, and HVAC systems.

- Q: Are aluminum sheets magnetic?

- No, aluminum sheets are not magnetic. Aluminum is a non-magnetic metal, which means it does not have any magnetic properties. This is because aluminum does not contain any magnetic elements, such as iron or nickel. Therefore, aluminum sheets do not attract or interact with magnets.

- Q: This question asks for methods to preserve an aluminum window and prevent rust or corrosion.

- <p>To maintain an aluminum window and prevent rusting or corrosion, follow these steps: Regularly clean the window with a mild detergent and water to remove dirt and grime. Avoid using abrasive cleaners or tools that could scratch the surface. Apply a protective coating or sealant designed for aluminum to shield it from moisture and environmental factors. Ensure proper drainage around the window to prevent water accumulation. Regularly inspect the window for signs of damage or corrosion and address any issues promptly. By following these maintenance practices, you can prolong the life of your aluminum window and keep it in good condition.</p>

Send your message to us

Sheets of 3/4 Thick Continuous Casting Aluminium Coil for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords