Vertical Turbine Long Shaft Submersible Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview of vertical turbine long shaft submersible pump

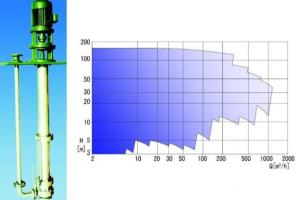

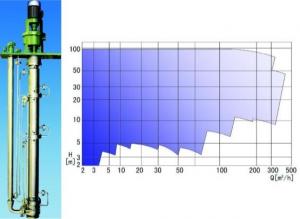

LP series vertical turbine long shaft submersible pump are new generation and energy-saving equipment for lifting water.

They are with advanced structure, we adopts the core produced with the resin sand and the impeller & diffuser adopts the new technique that top coated with easy, advanced hydraulic model, excellent performance curve without hump and wide efficiency range.

The efficiency is 4-8%higher than that of common deep well pumps structure in average, for this kind pump use whirl sand device and the maze-like structure which makes sand not able to enter the bearings shaft checked by flame method to ensure it’s in line, it’s a new generation design.

Operation Condidtions and Standard of vertical turbine long shaft submersible pump

Capacity: Up to 72000 m3/h

Head: Up to 260m

Pump Supporting Program of vertical turbine long shaft submersible pump

We value the energy saving and environmental protection, by analyzing the requirements of media and operation environment, adopt optimal materials to make the pump operate safely, reliably, economically.

FAQ

Q: How can I get trained on CNBM products?

A: Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

Q: Are your pumps cheaper than those of your competitors?

A: CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

Q: Do you have self-priming pumps?

A: Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

Q: Is it really necessary to fit a bleed valve for the boxes?

A: It is always best to have a bleed valve as the gas produced by the fermenting sewage is potentially hazardous.

Q: If I increase the power of the motor, must I also increase the power of the inverter?

A: You must select the size of converter that allows maximum absorption of the electric motor.

- Q: Hello! Can someone please tell me where the water pump is located on this vehicle? Or where I might find the answer to this question?Thanks!

- You see the big hose that enters your rad on the top well follow that hose and see were it comes from the engine..and that's the water pump..pretty simple thing to find my friend..good luck

- Q: I just move to this house, it's been empty for a while. The water pump keep screeching everytime I turn it on. What can I do to get rid this noise?

- Is there water in the system? Pump bearing worn Find a bleed point on the pump and vent any air from it with the pump Off.

- Q: Stop the engine immediately and stop the circulating pump and the condensate pump. What's the harm to the turbine?

- Stop the condensate pump is not required to condensate users, such as reducing water, mechanical seal water, shaft seal cooling water, deaerator, whether you need water. Stop circulating pump requires three: 1, exhaust steam temperature below 50. 2, there is no circulating water users. 3. No drain to condenser. If stop immediately stop circulating water and condensate pump, the consequences can be imagined.

- Q: I have an 02 Gran Prix and my water pump is going out. With the recession I don't have the money to take it in. So can anyone give step by step instructions to help me fix it. I am a do it yourself kinda of guy so I am mechanically inclined. What tools will I'll need? is there a timing chain? How long will you think it will take me? Any thing i should pay attention to? How can I measure the pounds of torque that I put on the bolts or what tool will I'll need? Please help!!!

- WP replacement mini-writeup 1. Empy Coolant from Radiator drain 2. Remove SC and Acc. belts 3. Remove the coolant resevoir tank 3. Remove the Idler pulley with a 15mm 4. Remove the 4 WP pulley bolts with a 8mm 5. Remove the 2 Power Steering Pump bolts with a 13mm(bolts are at 12:00 and 6:00 accessable through the PS pulley holes) 6. Push PS pump 1 inch to the side 7. Remove all 8 WP bolts with a 13mm and a 10mm(3 are 13mm/5 are 10mm) 8. Collect extra coolant until flow stops(a few cups) 9. Apply RTV to both sides of the gasket and WP bolts 10. WP bolts should be torqued to 11lbs+80*/Idler pulley bolt at 36lbs/WP pulley bolts at ~9lbs 11. Reinstall everything and fill the coolant back up 12.

- Q: i hear water swirl in my dash board when i take off and when i reverse, i heard its the water pump pushing water through the heater core, but how can i fix it.?

- Have radiator flush done. Low or air in system

- Q: i just moved into a house that has a small (about 40 gal) pond. i wanted to put fish in it. i have everything but the water pump. i've been looking around and i've found many solar fountain heads (about $30) that are pretty cheap and then i found a solar oxygenator for $100. which one would help the fish more? flowing water or just oxygen?

- To be quite honest, they are roughly the same thing. For a small pond all you need is something to agitate the surface of the water. the carbon dioxide/oxygen exchange only occurs on the surface therefore a small fountain that agitates the surface would work, or a small air pump that causes bubbles. Both are just fine.

- Q: We've changed the hoses, and thermostat for the radiator. It still leaks coolant but we can't find out where it's leaking from.

- 1999 Honda Accord Water Pump

- Q: The diving pump in the aquarium stops and stops on the goldfish

- Generally do not close the filter at night, at 56 in the morning when the most likely hypoxia. The sick fish are all fished out. Fast infection

- Q: What is the difference between a sewage pump and a clean water pump? Why can't sewage be pumped with clean water?

- The clean water pump and the sewage pump are different from the design. It also requires different material. Sewage pump requires material of solid phase friction, acid and alkali corrosion resistance, and other high resistance, and clean water pump can ignore these requirements. In addition, the sewage pump in a large proportion of large solids content of the fluid can also work normally, and clean water pump in the design can not meet the long-term use of this environment requirements.Of course, clean water pump can also be used for sewage, but only temporary measures, and the life expectancy, the effect can not be guaranteed.

- Q: i know a little bout cars always fixed my own since day one but this is the first car i have ever had/workd on with a internal water but thats driven off timeing chain my cars running hot and its holding prusser so i know its not radator or hoses but i need to know a way to check and make sure its the water pump befor i go tearing the engine apart

- When the car is running feel the hoses to see if the bottom hose is warm or not. If it is a lot cooler than the top one the water pump may not be working. Also turn on the heater to see if there is heat in the car. If there is heat inside the car the water pump is working. If the car is running hot while driving around town but runs cooler while driving on the highway the cooling fan may not be working properly. That car has a two stage cooling fan that is known for going bad. The low speed setting is the speed that is normally used and the high speed setting is used when the air conditioning is on. With that in mind you can try turning on the air conditioning to see if the motor cools down when it is hot. You will also want to see if the fan is coming on at all before you go too far and check the fuses and relays before you assume the fan motor is bad because they are around $100.00. Also I should note that I assumed that you have already checked the fluid level and thermostat. If not you need to check that first. Hope i have been helpful.

Send your message to us

Vertical Turbine Long Shaft Submersible Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords