Vertical Mixed-Flow Submersible Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Axial-Flow/Mixed-Flow Submersible Water Pump

1.Structure of Big Capacity Axial-Flow/Mixed-Flow Submersible Water PumpDescription

ZLB type axial flow pump is characterized by its large capacity, low head, etc. It can transport clean water whose temperature is less than 50º C, and also other liquids with physical and chemical properties similar to clean water.

Application Area:

Large-small type axial flow is widely used in agricultural irrigation, water supply and drainage for city, circulation water for thermal power plant, water level for dock, aquaculture, salt field pool and other hydraulic projects. Large type axial flow is mainly used in a large area of agricultural irrigation, interbasin water transfer and drainage for low-lying area, lake area.

2.Main Features of Vertical Submersible Axial Flow / Mixed Flow Water Pump

• Compact structure, good appearance, low construction

• Long Shaft

•Operation stably,high efficiency

•Convenient installation and maintenance

•Customized design is available, OEM and ODM are welcomed.

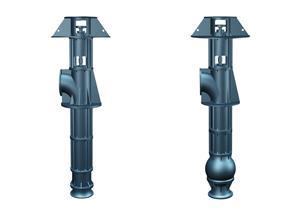

3.Vertical Submersible Axial Flow / Mixed Flow Water Pump Images

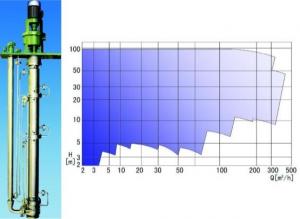

4.Vertical Submersible Axial Flow / Mixed Flow Water Pump Specification

Material | Cast iron, stainless steel |

Pump diameter | 350-1800mm |

Capacity | 400-80000m3/hr |

Discharge | 1-30m |

Power | 4-2000KW |

Max water temperature | 50ºC |

Medium volume ratio | < 2% |

Medium max density of | < 1.2×103kg/m3 |

Medium | lightly contaminated water |

5.FAQ

①What is the applications?

ZLB axial flow pump are used in flood dewatering application, water supplying and dewatering in urban area, storm-water drainage, agriculture and industry water supplying, water transfering etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q: Building installation problems, beginners, many problems need to be solved, thank you!

- Because each manufacturer's label is different, the country although some specifications, but not enforced, so purely from the literal meaning is difficult to explainWe will try to solve the following problems:WQ-- sewage submersible pump80-- outlet diameter of water pump40 - M /h fand flow15 lift M1600 speed, r/min4Kw powerAs for J, Y is rated as sealed form and waterproof gradeI don't know whether it is correct or not

- Q: Which professional friends ask, I encountered a problem in the design of fire pump head 90 meters, flow rate is 20/S, power is 37KW, but the construction side to buy the pump head and flow are achieved, but the power is only 30KW, this relationship? If you can, let me know by the way, thank you

- The flow is 20 L/S! Q = 20, L/S = 0.02 m^3/SThe total efficiency of the pump and the motor is estimated to be 60%P=pgHQ/n=1000*9.8*90*0.02/60%=29400W= 29.4, KWLook at the water pump motor power 30KW just enough from the calculation, but there is no room for the use of the attention do not overload!(Note: motor power matching pump nameplate are generally too large, room.)

- Q: About 3 weeks ago our water stopped. We replaced the switch at the pump and it was fine. Today when I was running water, it stopped again. I went and flipped the breaker on it, but it still didn't come on. About 20 minutes later, it started working again. Have you ever had this happen or do you know what the problem could be?

- You mentioned that you flipped the breaker...was the breaker tripped? If so...then your pump is overheating, and tripping the breaker. Possibly some bare wires rubbing together in the well pipe might cause it too. If the breaker isn't tripping...then you may have a problem with the well itself. If it's going dry...the pump will shut itself down when the water stops flowing through it...rather than sit there and run until it burns itself up! Hopefully it's just a bad breaker! :-) Good Luck!!

- Q: I replaced the water pump on my 1997 acura cl 3.0 v6 vtec. I set the timing how alldata said to. (Lined up marks on timing drive pulley and both cam pulleys) and put it all back together. Now when I start it the motor runs rough for about 45 seconds then it smooths out but won't rev past 3000 rpm. What are some possibilites it could be?

- reset the ecu, by disconnecting the battery cables off the battery for 30 mins and then reconnect them and see what happens

- Q: need to know how to change water pump of my plymouth voyager its a 96 and motor is a 4.

- Ummm I kind of agree and disagree with C-tech. the 96 Voyager came in one of 3 four cylinder engines, 2.2.L 2.5L or , 2.5L turbo, I think the 2.6L was discontinued in the late 80's or around 91. And the water pump is driven externally, Just look under the alternator and you will see it. So remove the alt, remove the bracket then unbolt the whole pump/pump housing assy, then unbolt the housing from the pump. Clean the surface where the o-ring seals the housing to the block, Run a bead of silicone on the cleaned housing to pump surface, bolt together (dont glob on the glue) Install the housing to the block with a new o-ring, and finish the assy.And to even make sure you have a 2.2 or 2.5 right where the thermostat goes, the head has a housing cast on the head there is a galley plug. Slightly tighten then remove the plug, pour in the coolant ( in the radiator)water mix (50-50) install plug then run engine, what for fan to kick in, then wait for fan to shut off, set your level in the reservoir and BAMM your done. And where I do agree with C is when MBZ owned Chrysler and had the 2.4 installed, somewhere in the 00, but I dont know, I quite Chrysler in 99 And if its a 2.6 get a mechanic to do it

- Q: When should I replace my water pump ?

- usually when leaking or noisy

- Q: How do I tell the difference between a long and a short water pump? I have a Chevy 350 V8, a crate motor the same size is going in very soon. How do I tell which one I have so that I can get the correct brackets, accessories, etc.?

- The short water pump body measure about 3 1/8, while the long pump measures about 4 3/4. That's measured from where the pump bolts to the block to the outside part of the casting. Not including where the shaft is. If you're looking straight down over the motor and it has a short pump, then the front of the timing chain cover and the rear of the pump are almost on the same line. If it's a long water pump, then looking down there would be about a 7/8 space where you can stick your finger. But don't do that, you could hurt yourself. :-) Hope this helps.

- Q: i started backing out of my garage and something sounded like it poped then lots of steam started coming out and water was on the ground on the right side of the car non on the left and the water pump needle in my car is all the way to the red can some one help me

- need new water pump if that is where it leaked from but most likely the hose blew on it check it out before water pump

- Q: About how to calculate the pump installation height?

- When the water temperature is 4 degrees centigrade, the water pump is installed on the theoretical height of 10.33 meters, is the atmospheric pressure to the hydraulic pump inlet to the level of theory, in practical engineering, the water flow in the pipeline will produce resistance and other factors, the actual installation height generally less than 7 meters. The installation height limit of the pump shall be less than the design suction stroke of the pump.

- Q: the question i have is can the pump be turning and not leaking but not pump water??? i know the olden days (the good ole days) as long as the impeller was turning it would pump water! leaking seal is when it went bad,or locked up..like a box fan blade as long as it is turning its moving air...

- Yes, the impeller could be broken. Believe it or not, the belt could be on wrong. If by chance it was replaced recently, it is possible to put the belt on the wrong side of the pulley. It should be running on the bottom side, not the top-next to the little plastic cover.

Send your message to us

Vertical Mixed-Flow Submersible Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords