Vertical Can-type/Barrel Pump .

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

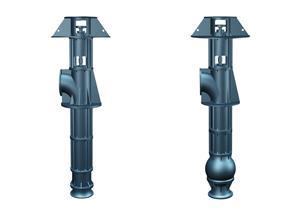

1. Description

Vertical barrel pumps are multistage, radically split with an outer casing. Fist stage impeller is generally suction impeller, the axially forces are balanced by a thrust ball bearing. Balancing the drum structure can be accomplished when the differential pressure is large. The outer casing only bears the suction pressure, the length of the outer casing and the pump installation depth depends on NPSHr performance requests. If the pump is installed on a tank or pipeline, the outer casing is not necessary.

Light oil lubricated, it has an independent internal recycle automatic lubrication system. Hydraulic dynamic bearing is in the suction end of the pump. Suction and discharge is above the installation flange.

2. Application

Suitable for various liquids include clean or dirty, low temperature or high temperature, neutral or corrosive

Low temperature engineering, power plant

Pipeline pressure increasing

Petrochemical offshore oilfields

LPG engineering

Refinery

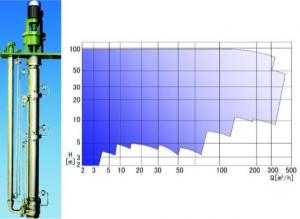

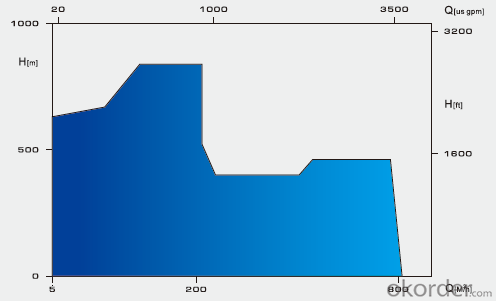

3. Technical Data

Size: DN 40~200mm

Capacities to 800m3/h (3522GPM)

Heads to 800m (2625ft)

Pressure to 10MPa

4. Pump Performance

5. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

- Q: ok so im wondering if there is a water pump out there i can buy that automatically turns on when i turn the tap on. i looking for something thats strong enough to pump enough water to more than one taps at a time i.e kitchen tap, bathroom etc.

- See okorder /

- Q: How can we calculate the maximum pump pressure for chilled water system for a 20 story building

- In addition to what was said earlier you will also need to consider the following. Pipe frictional losses will need to be calculated. If there is a control valve or flow element then need to add 3 to 5 psi. If the chilled water goes thru a piece of equipment there will be a pressure loss across that, (example - cooling coil on an air handling unit, air separator etc) this can range from 3 to 20 psi, the equip vendor should be able to provide this. If your pumps are on the ground floor, you might be able to neglect the pressure due to elevation if the loop remains pressurized by the pump(s). Might be a good idea to have an engineer review this who has sized pumps before.

- Q: I need a 12v water pump capable of at least 40psi. The only website that i found is one where you have to order a minimum of 100.

- Maybe at a sporting goods store.

- Q: Weap seal is starting to leak and getting some noise from the water pump. These cars are not as easy as a 1969 Camaro to change the water pump. Can you please give me some guidance? Thx in advance.

- 2001 Chrysler 300m

- Q: My truck has been over heating, and I cant figure out whats going on...the only thing that gets really hot is the upper radiator hose, and the radiator....I just noticed there was a plug unhooked from the water pump, what does that do? Or maybe it could be the thermostat? It just overheats, and when I park it, it wont start half the time, usually I can let it cool off and go, but sometimes it just dies and I have to let it cool off and jump it off.

- I doubt its your water pump. That plug may have been just the temperature sensor. Definitely sounds like a bad thermostat. Replace it. They aren't expensive at all. Letting your truck over heat does serious irreversible damage to the engine. You may have significantly shortened the life of your engine already. Just replace the thermostat when the truck is COLD, never when its hot. If it still overheats with the replacement thermostat, your radiator may be clogged.

- Q: does any one know where the water pump is located on a 97 nissan altima? and where can i find one, would pep boys have one?

- most cars, it is in the front, driven by the timing belt. If you are going to replace the pump, replace the timing belt also (if there is one), as it's probably overdue, and you have to remove it to get at the water pump. Also the tensioner. Replacing the timing belt is a difficult task. If you screw it up, you could damage the engine. .

- Q: How does a pump get water from a low low elevation to a higher elevation.

- Natural okorder /

- Q: What does the lift of a pump mean?

- Simply from the local to the pumping pumping height calculation of rice

- Q: I have oil all over my water pump. I investigated when I saw a few drops of oil in the garage that showed up every few days. I then saw a drop of clean radiator fluid. Does oil come near or through the water pump? I have a 96 nissan maxima if that helps.

- get the cylinders checked for pressure. Check the spark plugs for fouling and oil in the radiator. It sounds like you cracked a block.

- Q: I am new to saltwater tank, and i what to add a sump to my tank, but I don't know what to add to it. what water pump? do i add the filter to the sump or does the filter stay in the tank.

- If you're using a sump, the pump you use will have to be chosen based on the size of your tank and how much flow you need. The kinds of fully submersible pumps that are used for ponds and other aquarium applications are best. You really could put your filter on either, but most people I know that keep saltwater [and myself included] keep filters, heaters, and skimmers in the sump so they're out of sight. This also gives you more room in the display tank for live rock and fish if the equipment isn't crowded in there. All you really need to have in the display are powerheads to keep the water circulating so dead spots don't build up. And without the equipment hanging on the back, and only power cords coming out, you can use a glass cover to reduce evaporation and keep your fish from jumping out.

Send your message to us

Vertical Can-type/Barrel Pump .

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords