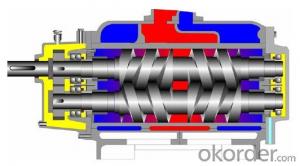

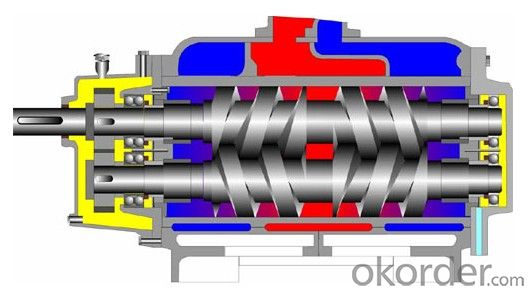

Twin Screw Pump for Oil Production and other Viscous Medium

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Twin Screw Pump for Oil Production and other Viscous Medium

No stirring, pulse free

Gas-liquid conveying

The working surfaces of rotors are free from contact and short-time dry running can be realized

It can be used for conveying of various non-lubricating media due to an outboard bearing

Various structures including horizontal, vertical and heating jacket

It can be used for conveying of various low viscosity or high viscosity media free from solid particles

The accurate part materials can meet the requirements of conveying corrosive media

Conveying Medium of Twin Screw Pump for Oil Production and other Viscous Medium

Petroleum Products: Crude oil, heavy oil, fuel oil, lubricating oil, asphalt, tar, diesel, kerosene, gasoline, light dydrocarbon, butadiene, ketone benzene, phenol

Chemical Products: Acid, alkali and salt solution, latex solution, resin pigment, ink, paint, glycerol, paraffin, high molecular polymer, cosmetics

Multiple Configurations of Twin Screw Pump for Oil Production and other Viscous Medium

Drive: Direct motor drive, variable speed drive, diesel drive, hydraulic motor drive

Shaft Seal: Single and double end face, bellows mechanical seal, packing seal

Heating: Full-automatic electrical heating, bottom heating, jacket heating

Washing and Cooling: Mechanical seal washing system, water cooling device for bearing

Materials: The parts can be made from different metal materials

FAQ of Twin Screw Pump for Oil Production and other Viscous Medium

Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

Do you have self-priming pumps?

Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

Is it really necessary to fit a bleed valve for the boxes?

It is always best to have a bleed valve as the gas produced by the fermenting sewage is potentially hazardous.

If I increase the power of the motor, must I also increase the power of the inverter?

You must select the size of converter that allows maximum absorption of the electric motor.

- Q: Got pump ready and will not pump water. Have tried all things suggested to prime but will not pump water

- all i can think of is it may not want to lift water real high if the intake is way lower than the pump, and be sure the hose is secure and its not sucking air .. if the thing has a plug on top remove it and fill it with water first ..

- Q: So I purchased this car last week. It ran great for three days until it started leaking water so much that it caused it to over heat. My uncle checked it out for me and said it was either the seal or the water pump. Yesterday we replaced the seal and still leaking water. So we now know it is the water pump. My uncle and every mechanic I know has turned down the job saying it is too much work. I even called two small shops yesterday and got turned down saying it was too much work. It is Sunday so most mechanics are closed. Can anyone give me an estimate on how much this will cost. The problem is everyone is saying that the pump is located inside the timing belt which is hard to put back after replacing the pump. Anyone ever have this repair done before or know a price range. I am a college student and need this car running asap and only got about $500 i can put into it. It is a V6 engine.Thanks

- 91 Plymouth Acclaim

- Q: Hello everyone, is the general household deep well pump capacitor how to pick up ah, 220V voltage, a capacitor, capacitor, there are 2 lines, but the motor is 3 lines, how can I put these 7 lines together?.Please don't copy professional theories from others.

- 1) in a line in the AC220V string into a large light bulb (Bai Chideng), and then the capacitor as shown in figure A, then, that B and C are three terminals; 2) the number of pump motor three lines 1, 2 and 3; 3) A, B, C and 1 2, 3, a total of six kinds of wiring combination: ABC/123, ABC/ 231, ABC/321, ABC213, ABC132 ABC312; 4) you have a a try, if you can turn up, and the fastest start wiring is correct, 5) if not turn up, you have to increase the number of watt bulb, such as 200 watts, 300 watts, 500 watts...... With a few 100 watt parallel one; 6) string into the bulb is designed to prevent the current is too large, it certainly must be removed after determining the connection method; 7) there is no suitable bulb that according to the motor power generation to choose the appropriate insurance.

- Q: explain the operation of a water pump....?

- There are a number of different types of water pumps that operate according to different principles. For lots of information, including pictures and diagrams, do an internet search on water pump.

- Q: how to replace water pump 97 pontiac bonneville?

- It depends on which engine you have, with or without a supercharger. The non-supercharged engine is a piece of cake. the supercharged one is a bit of a pain to get at the water pump. On the non-supercharged engine, all you need to do is remove the serpentine belt, the water pump pulley and the bolts that hold the water pump to the front cover. I have detailed instructions if you send me your email address I can give them to you. They are from GM Service Information website. I can't give you the link to the website because I have to enter a password to enter the site through work.

- Q: Installation position of check valve for water pump

- Check valves must be installed at the pump's exit and position before the outlet control valve for servicing the check valve.Jiang Yuanyuan 1985's statement has a problem:1. On the flow of water, because the fluid is continuous and incompressible, the water in any part of the pipe will not flow as long as it is cut off in any position in the pipe.2, self suction exhaust is formed within the pump in outlet pipe, check valve installed in the inlet, because the pressure is low, is not conducive to automatically open the check valve, and its resistance, easy to form a vacuum pump and cavitation.

- Q: I Need a water pump, no matter its fountain pump or high stream pump. But the things or you can say the parameters i required in that pump is, 2 inch minimum outlet from where the water come out, pressure 130 or above (in PSI) runs wid a 1 or 2 Horse Powered motor not more then 2HP. And the pressure calculation is flow of the water (130 Psi) , like while water is streaming out.Any one who can sugest some water pumps which can fulfill or near or above to my requirements. thanks alot sir for you kind time.

- With 100M of 'head' you're going to need a constant displacement pump, and high pressure piping. I'd consider an intermediate lift station.

- Q: I just bought a 1997 Honda Civic, done about 85k. There is no record of the timing belt having ever been changed so I want to get this done as a priority. My usual mechanic can't do it for a month due to other commitments so I have been ringing round for quotes, and generally these have all been to change the belt quot;plus the kit- which makes sense, change the lot while you are in there.Surprisingly, the cheapest quote I have had was from my local Honda dealer, however, they have said this is for the belt only as they don't change the tensioner/water pump on this model. Are they full of it? I'm not sure whether to take this as expertise from the car's manufacturer or total BS from some chancer trying to make money from us having to come back when other things go wrong!

- We have owned Honda's for years, including three 90's Civics. We have had the timing belts changed by the dealer also - also the cheapest price - and they have always recommended changing the tensioner and the water pump while in there. The timing belt is such a critical piece of equipment that is should be changed on schedule. The new belts go much longer than the old belts. But it's only a hundred more at most to have the water pump replaced at the same time so make them do it. If you water pump goes out in another 20000 miles, the labor charge to get to it will be 400 or 500 bucks. Most dealerships will do the water pump for parts cost markup if they are also doing your timing belt. You can also negotiate your price with a dealership. Try it. If they won't budge, find a new dealer.

- Q: when i drove my truck after about 15 minutes i was parked and let my truck idle afetr about a minute of idling my truck stalled and when i turned it back of it was squeeking and made some noises for about ten seconds and then stopped. I noticed that the pully on my fan coming from the water pump was wobbling. my tempuratue was still normal what could cause this i am suspecting taht the bearings in my water pump went?

- After the pully starts to wobble the next thing is the fan comes off and tears up the radiator. If you are going to do it yourself you can rent the tool to remove the fan at Auto Zone or Advance and remember it has left hand threads. Its best to remove the fan before the belt, it will hold the pulley while you smack the wrench with a hammer to break the fan loose. You don't have to but I always recommend new by pass, tiop and bottom radiator hose ans a new thermostat. You'll find that if you unbolt and lay aside the a/c compressor and alternator and breather it is not a hard job.

- Q: Water is leaking from the front of my car, on the right where the radiator is located. only thing is that its not leaking a lot, just a little.... but people keep telling me that my timing belt is going to go out and that i will be stranded!. i will like to know the cost of both the water pump and timing belts for my 2001 PT Cruiser please.

- replace water pump timing belt pt cruiser

Send your message to us

Twin Screw Pump for Oil Production and other Viscous Medium

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords