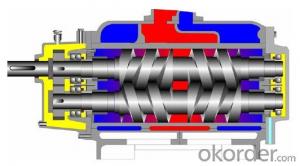

Horizontal Heavy Oil Twin Screw Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Working Features

Wide application, delivery all kinds of fluid media, even non-fluid ones

Bilateral rotation and delivery

Stable capacity and pressure, no pulse

Capacity is proportional to speed, so the pump can be used as dosing pump

Low operated noise, no-leakage and no temperature rise

Long life, low cost of operation maintenance

Delivery Media

Different viscous liquids, especially for the liquids with high viscosity which are difficult to be pumped. (up to 106 mm2/s)

Different dense liquids and dewatered dry medium

Liquids with solid particles (up to 70%), fibers (up to 350mm) and suspending media

Sensitive liquids that cannot be churned, sheared and compressed

Corrosive liquids (pH=0-14)

Fluid at high or low temperature (-10 – 150 C)

Application Fields

Environmental Engineering

Paper Making Industry

Oil Industry

Electrolyte Treatment

Mine Industry

Food Industry

The Material of Components Depends on Medium Features

Pump body (suction chamber, discharge casing and others) which connects with media:

cast iron, carbon steel, different stainless steel or flow surface plated with anti-corrosive materials are available;

Rotor: strong anti-abrasive alloy steel, different stainless steels and anti-corrosive alloy steel are available;

Stator: different rubber and other elastic materials are available;

Axial seal components: packing or mechanical seal according to your requirements.

- Q: Fire pump and shower pump flow head selection, high resolution.

- 2, the volume is greater than 10000 is less than 25000, the minimum water consumption of indoor fire hydrant is 15L/s

- Q: A residential building with a floor height of 11 stories and a roof height of 33 meters. The height of the water tank is 37.7 meters. The basement is -3.3 meters, only set fire hydrant, fire pump only consider the indoor fire water, fire flow should be 10l/s. Now select a fire pump, concrete should be much traffic, big head, flow determine how? How to determine the head, I hope to say some more detailed, thank you, and there is to explain this question, why is the fire pump lift 120?. Thank you

- Such as a large pressure of about 10m or about 0.1MPa} because the most unfavorable point fire hydrant requires more than 0.07MPa (7m) and 0.5MPa (50m) is not greater than the pressure, so unless the pump is located in the 50m Valley is still lower than the garage, or add to the valve (or the use of fire hydrant decompression) otherwise, it is 120m lift pump

- Q: 5 floor water pressure is too low, what kind of water pump is better?

- The location of the pump is too far away from the pumping pool, the suction of the pump is not enough, cavitation phenomenon, pumping water, this water pump manufacturers, the pump will be placed in a reasonable position

- Q: How many millimeters is the diameter of the water outlet of the four inch pump?

- Here is a 4 inch inch, not rural, 1 inches =25.4 mm, 4 inches is approximately 100mm, with DN100 pipeline.

- Q: What is the "variable" of a variable pump? Is the displacement change or the flow change? Thank you

- Variable pump variable refers to the flow can be changed to distinguish from the constant flow of quantitative pumps.

- Q: What are the application areas of pumps?

- 1, urban water supply 2, sewage system 3, civil and construction systems 4, agricultural water conservancy system 5, power station system6. Chemical system 7, petroleum industry system 8, mine metallurgy system 9, light industry system 10, ship system

- Q: Brief description of centrifugal pump on / off operation

- First, the preparation before the start(1) carefully check the inlet and outlet pipe line, valve, flange and pressure gauge joint of the pump, whether the installation is safe, comply with the requirements, whether the flow is correct, whether the anchor bolt and other connecting parts are loose or not.(2) add lubricating oil to the bearing case, and the oil level is 2/3 of the gauge of the bearing box.

- Q: When the water pump is started, why should it start when the outlet valve is closed? Thank you

- The valve opening pump is aimed at the centrifugal pump.From the power curve of the centrifugal pump, the power of the centrifugal pump increases with the increase of the flow rate; the flow curve of the centrifugal pump shows that the flow rate of the centrifugal pump decreases with the increase of the head.

- Q: What does "dual purpose" of water pump mean? Please expert advice

- 2, the pump must pay attention to maintenance after use, for example, when the pump is used up, the water pump should be put clean, it is best to remove the water pipe, and then rinse with water.5, the water pump on the tape should be removed, and then rinse with water after drying in the light place, do not put the tape in the dark damp place. Water pump tape must not be stained with oil, not to tape coated with some sticky things.6, to carefully check whether there are cracks in the impeller, the impeller fixed to the bearing on whether there is loose, cracks and loose if the phenomenon to be timely maintenance, if the water pump impeller should also be above the earth clean.

- Q: What is the distance between the pump and the wall?

- What do you mean by that? If your pump is parallel to the wall! Then, the wall of the pump near the wall is usually 500mm. This is an empirical data, considering the import pipe length, pump maintenance and motor heat dissipation and other aspects of the situation to determine. Dozens of pumps installed in our company are placed in this size! Hope to be of help to you.

Send your message to us

Horizontal Heavy Oil Twin Screw Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords