Multiphase Mixture Pumps/Double Screw Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

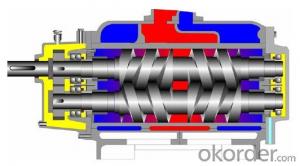

2W.W twin screw pump/ Multiphase mixture pumps/double screw pump

2W.W horizontal twin screw pump

1. Smooth liquid transfer, without pulsation and mixing

2. Small vibration and low noise

3. Strong auto-suction performance. For transfer of medium mixture, gas composition not

more than 80%, and sand composition not higher than 500g/m3.

4. Outboard bearing structure, indepent lubricant, can transfer for various non-lubricating media

5. Use synchronous gear drive, no touch between the two rotors, even run empty for short time is no problem

6. Pump body fit with heating jacket, can transfer various clean or media with small solid particle of high or low viscosity

(particle diameter less than 0.12-2mm)

7. Good selection of material can even transfer many corrosive media

8. Double-suction structure, have no axial force on the rotor

9. Use mechanical seal or bellows mechanical seal for shaft end, features long service life,little leakage and wide range of use.

10. Widly applicable for oil field, ship building industry, petrolegum, petroleum and petrochemical industries, thermal plant and food industry etc.

Main perfomance ranges for 2W.W series:

1 Max. pressure 4Mpa

2 Flow range 1-1000m3/h

3 Temperature range -20-120°C

4 Medium viscosity 1-3000mm2/s, if lower speed can 106mm2/s.

- Q: What is the difference between swashplate pump and crankshaft pump?

- Piston pump: valve plate, valve plate, piston, piston ring, crankshaft, connecting rod and so on, all belong to its spare parts.Piston pump working principle: by the piston in the pump cylinder for reciprocating movement to suction and remove liquid.

- Q: Working principle and diagram of axial piston pump with pressure compensation variable

- Adjust the flow characteristics, the first limit screw to the top, according to the flow and pressure changes in the required range, adjusting the spring set, the initial flow pressure began to change to meet the requirements, then the limit screw to the ultimate pressure when the flow is no longer changed, the relationship between flow and pressure the changes are determined by the pump itself.

- Q: Must the water pump in the tank be all soaked in water?

- Need a submersible pump in the water, but it is not entirely like this, I have to work for a long time no problem in water, but there is a problem you should pay attention to the water pump, at least in half, or stop when the smoke is not on water.

- Q: If the suction pump does not have enough suction range, you need to add a vacuum pump to increase the suction stroke. How do you install the suction pipe of the vacuum pump? Water pump impeller is not closed, it is normal that the vacuum pump is unable to pump suction pipe to a vacuum, is it because the water pump outlet pipe connected to the role of the check valve? But the water pump, outlet pipe, check valve sealing performance can achieve the function of non leakage?

- Vacuum suction principle of self suction pump:Assuming that the pump connected with the water inlet of a sealed container, the container has plenty of water, since the start of a water pump, water is thrown out of the water impeller pump body, water inlet seal vessel due to the extraction of water to form a vacuum cavity, this assumption will be connected to vacuum cavity and exposed to atmospheric conditions of water, water at atmospheric pressure under the effect of entry into the vacuum chamber".

- Q: What is cavitation, centrifugal pump cavitation phenomenon how to solve?

- Centrifugal pump cavitation phenomenon how to solve?:Measures to improve cavitation resistance of centrifugal pumps(1) improve the design of the suction port of the centrifugal pump to the impeller. Increase flow area; the radius of curvature increases the impeller cover inlet section, reduce the flow accelerated sharply with pressure; reduce the thickness of the blade, and the blade inlet rounded, close to the streamline, can also reduce the acceleration and pressure flow around the blade head portion of the impeller and the blade inlet part; improve surface finish in order to reduce the resistance loss; the blade inlet edge extends to the impeller inlet, the liquid flow in advance to accept work pressure, improve.

- Q: The difference between diaphragm pumps, vacuum pumps and centrifugal pumps

- The function of vacuum pump is to make vacuum, which has many kinds of structure, such as centrifugal, diaphragm (diaphragm), piston, liquid ring, rotary plate, jet type...................

- Q: What are the starting and stopping procedures for centrifugal pumps?

- The use of centrifugal pump can be divided into three steps, namely, start, run, stop.Start: you should do the following preparation before starting:(1) check the water pump equipment in good condition.(2) the bearings are filled with oil, the oil level is normal, and the oil quality is qualified(3) all the inlet valves of the centrifugal pump are opened.(4) pump water injection or vacuum pump diversion (except for flow), open the vent valve exhaust.(5) check the leakage of shaft seal. It is advisable to fill the seal with a little drop of water.(6) the motor rotates in the right direction.

- Q: Does the reservoir water heater press the booster pump (high marks)?

- 60 liters of water storage should be able to drive two bathrooms at the same time bath! Water storage water heater generally does not need booster pump, as long as there is a little pressure, the water heater is filled with water, as long as the tap water can do. You can turn off the hot water valve and see only the amount of water in the cold water. If hot water is much smaller than cold water, it is the reason for the heater. Can you check the water mixer is normal, the one-way valve is installed in reverse.

- Q: How is the pump level of submersible sewage pump determined?

- Below the top elevation of the sump, 200 is the warning water levelBut note: 1, the effective volume of the sump meets the requirements. 2, the pump should have enough submerged water level

- Q: Why adjust the centrifugal pump outlet valve can adjust the flow? What are the advantages and disadvantages of this method? Is there any other way to regulate the flow of the pump?

- The centrifugal pump at a fixed speed, the head is fixed, adjust the outlet valve to adjust the diversion area

Send your message to us

Multiphase Mixture Pumps/Double Screw Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords