Tabel formwork system for Formwork and Scaffolding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

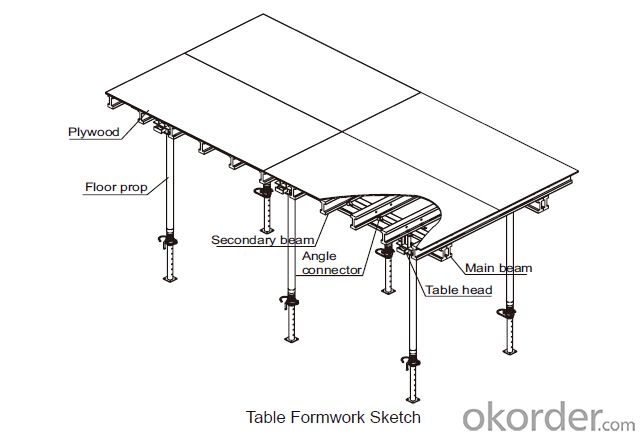

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: How does steel formwork handle concrete setting time and curing temperature?

- Steel formwork is a preferred choice for handling concrete setting time and curing temperature due to its excellent heat transfer properties and durability. Steel, being a good conductor of heat, helps in dissipating the heat generated during the hydration process of concrete, thus accelerating its setting time. This allows for a faster construction process and reduces the overall project timeline. Additionally, steel formwork can withstand high curing temperatures without deforming or deteriorating. This is particularly important in cases where concrete requires high-temperature curing to achieve the desired strength and durability. Steel's ability to withstand high temperatures ensures that the formwork remains intact and stable, providing the necessary support to the concrete during the curing process. Furthermore, steel formwork's strength and rigidity prevent any deformation or movement during the concrete setting and curing stages. This is crucial for maintaining the desired shape, size, and surface finish of the concrete structure. The use of steel formwork ensures that the concrete remains in place and does not experience any undesirable shifts or displacements during the curing process. In conclusion, steel formwork is an ideal choice for handling concrete setting time and curing temperature due to its excellent heat transfer properties, ability to withstand high temperatures, and its strength and rigidity. Its usage facilitates faster setting times, allows for high-temperature curing, and ensures the stability and integrity of the concrete structure during the curing process.

- Q: Can steel formwork be used for pre-stressed concrete elements?

- Yes, steel formwork can be used for pre-stressed concrete elements. Steel formwork is a versatile and durable option for constructing pre-stressed concrete elements. It provides the necessary support and containment for the concrete during the pre-stressing process, ensuring that the concrete maintains its shape and strength. Steel formwork is particularly suitable for pre-stressed concrete elements because it offers high load-bearing capacity and can withstand the applied forces and pressures involved in the pre-stressing process. It also allows for precise control over the form and dimensions of the concrete element, ensuring accurate and consistent results. Furthermore, steel formwork is reusable, making it a cost-effective choice for pre-stressed concrete construction projects. It can be easily assembled, disassembled, and adjusted to accommodate different shapes and sizes of pre-stressed elements. Overall, steel formwork is a suitable and commonly used option for constructing pre-stressed concrete elements due to its strength, versatility, and cost-effectiveness.

- Q: Can steel formwork be used for both simple and complex architectural designs?

- Yes, steel formwork can be used for both simple and complex architectural designs. Steel formwork offers excellent strength and durability, allowing it to handle complex shapes and intricate details with ease. It can be easily assembled and disassembled, making it suitable for various design requirements. Additionally, steel formwork provides a smooth and uniform finish, ensuring high-quality results for both simple and complex architectural designs.

- Q: Can steel formwork be used for both residential and commercial projects?

- Steel formwork can serve both residential and commercial projects effectively. Renowned for its strength and capacity to bear heavy loads, steel formwork is a flexible and enduring choice extensively employed in construction. Its adaptability enables convenient customization to cater to diverse project demands, irrespective of whether they pertain to residential or commercial ventures. Among its merits are notable advantages like exceptional concrete finish, swift assembly, and extensive reusability. In both residential and commercial construction, steel formwork finds widespread application in foundations, walls, slabs, columns, and beams.

- Q: What are the different types of safety precautions required when working with steel formwork?

- When working with steel formwork, some of the different types of safety precautions that are required include wearing appropriate personal protective equipment (PPE) such as hard hats, safety glasses, and steel-toed boots to protect against falling objects and accidental injuries. It is also important to ensure that the formwork is properly secured and stable to prevent collapse or accidents. Workers should be trained on safe lifting and carrying techniques to avoid strains and sprains. Additionally, regular inspections of the formwork should be conducted to identify any potential hazards or defects that need to be addressed.

- Q: What are the considerations when designing steel formwork for foundations?

- There are several important factors to consider when designing steel formwork for foundations. Firstly, it is crucial to carefully calculate and design the load-bearing capacity of the formwork to ensure it can support the weight of the concrete being poured. The strength and thickness of the steel used will play a significant role in determining its ability to withstand the pressure and weight of the liquid concrete without deforming or collapsing. Another important consideration is accurately replicating the desired shape and dimensions of the foundation. This requires careful planning and measurement to ensure the formwork is properly aligned and positioned before pouring the concrete. Any inaccuracies in the formwork can compromise the structural integrity of the building. Efficiency of installation and removal is also a key consideration. Modular or adjustable steel formwork systems can greatly improve the construction process by allowing for easy assembly and disassembly. This reduces labor and time requirements. Additionally, provisions should be made for easy access to the foundation for inspections or repairs during and after construction. Finally, the durability and longevity of the steel formwork should be taken into account. While steel is known for its strength and durability, protective measures should be implemented to prevent corrosion. Applying protective coatings or using galvanized steel can help prevent rust and extend the lifespan of the formwork. In conclusion, when designing steel formwork for foundations, it is essential to consider factors such as load-bearing capacity, accuracy of shape and size, ease of installation and removal, and durability to ensure a successful and structurally sound foundation.

- Q: How does steel formwork handle different concrete surface repair techniques?

- Steel formwork is highly versatile and can easily accommodate various concrete surface repair techniques. Its strong and durable structure allows for the application of techniques such as surface grinding, shot blasting, or sandblasting to remove damaged or deteriorated concrete. Additionally, steel formwork provides a smooth and stable surface, enhancing the effectiveness of techniques like patching, skim coating, or the application of bonding agents. Overall, steel formwork is compatible with a wide range of concrete surface repair techniques, making it a reliable choice for handling such repairs.

- Q: Can steel formwork be used for structures with high fire resistance requirements?

- Yes, steel formwork can be used for structures with high fire resistance requirements. Steel is known for its excellent fire resistance properties, as it does not burn or contribute to the spread of fire. Steel formwork can withstand high temperatures and maintain its structural integrity, making it suitable for use in fire-resistant structures.

- Q: Can steel formwork be customized to meet specific project requirements?

- Yes, steel formwork can be customized to meet specific project requirements. Steel formwork is highly versatile and can be easily modified and fabricated to fit any shape or size needed for a particular project. This adaptability allows for greater flexibility in construction, ensuring that the formwork meets the precise specifications and dimensions required for the project.

- Q: How does steel formwork contribute to easier formwork removal?

- Steel formwork offers several advantages that contribute to easier formwork removal. Firstly, its high strength and durability enable it to withstand the pressure and weight of the concrete without deforming or warping. As a result, the formwork remains undamaged and intact after the concrete is poured and cured. Secondly, the smooth surfaces of steel formwork facilitate the easy release of the cured concrete. The absence of sticking between the concrete and the formwork simplifies the removal process, especially when dealing with complex shapes and intricate designs. Consequently, the formwork can be removed effortlessly without causing any harm to the concrete. Moreover, steel formwork often incorporates detachable parts or panels, allowing for convenient assembly and disassembly. This feature not only speeds up the removal process but also simplifies the cleaning and maintenance of the formwork. Consequently, the formwork remains in good condition, ensuring its longevity and reusability. Additionally, steel formwork exhibits remarkable resistance to moisture and chemicals commonly encountered in the construction environment. This resistance prevents the formwork from deteriorating or weakening over time. Consequently, the formwork remains intact and in excellent condition, making it easier to remove after the concrete has set. In summary, the strength, durability, smooth surfaces, detachable parts, and resistance to moisture and chemicals make steel formwork an ideal choice for easier formwork removal. This not only simplifies the process but also guarantees the quality and integrity of the concrete structure being constructed.

Send your message to us

Tabel formwork system for Formwork and Scaffolding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords