Tabel Formwork system for Formwork and Scaffolding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

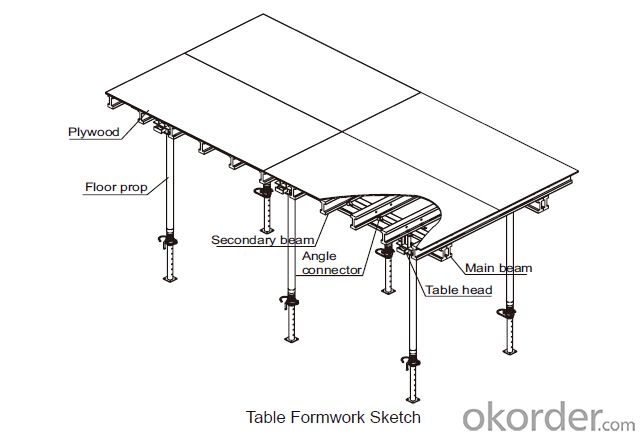

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel formwork be used for structures with high corrosion resistance requirements?

- No, steel formwork may not be suitable for structures with high corrosion resistance requirements. Steel is prone to corrosion when exposed to moisture and certain environmental conditions. Over time, this corrosion can weaken the formwork and compromise the structural integrity of the concrete. To ensure high corrosion resistance, alternative materials such as fiberglass, aluminum, or plastic formwork may be more appropriate. These materials are resistant to corrosion and can withstand harsh conditions, making them suitable for structures with high corrosion resistance requirements.

- Q: Plastic building templates where there is an urgent need to solve

- Three, release simple. The concrete does not touch the surface, without the release agent, easy demoulding, easy to clear ash.Four, stable weather. The mechanical strength is high, under the condition of the temperature of -20 DEG C to +60 DEG C, the utility model has the advantages of no shrinkage, no expansion, no cracking, no deformation, stable size, alkali resistance, corrosion resistance, fire resistance, water resistance and insect repellent

- Q: How do steel formwork systems differ from one another?

- There are several ways in which steel formwork systems can vary from one another. Firstly, their design and construction can be different. Certain systems are modular and consist of pre-assembled panels that can be easily connected and adjusted to create various shapes and sizes. On the other hand, there are custom-made systems that are specifically tailored for particular projects, offering more flexibility in formwork design. Secondly, the strength and durability of steel formwork systems can differ. Some systems are engineered to withstand heavy loads and extreme conditions, making them suitable for large-scale construction projects. Conversely, there are lighter and more portable systems that are better suited for smaller projects or areas with limited access. Another aspect that sets steel formwork systems apart is their user-friendliness. Some systems are designed to be easy to use, with built-in handles, adjustable brackets, and user-friendly locking mechanisms. These features allow for quick and efficient installation and dismantling, saving time and effort on the construction site. Furthermore, steel formwork systems can offer different finishing options. Some provide smooth and precise finishes, which are ideal for projects that require a high-quality surface. Others have textured or patterned finishes, adding a decorative element to the concrete structure. Lastly, steel formwork systems can vary in terms of their cost and availability. Some systems are more affordable and readily available, making them a popular choice for smaller projects or contractors on a tight budget. On the other hand, there are systems that are more expensive or require longer lead times for fabrication, but offer advanced features or customization options. In conclusion, the distinctions between steel formwork systems lie in their design, strength, ease of use, finishing options, and cost. Contractors and construction professionals should carefully assess these factors to choose the most suitable steel formwork system for their specific project requirements.

- Q: How does steel formwork handle concrete finishing and curing agents?

- Steel formwork is a highly durable and versatile material that is specifically designed to handle the concrete finishing and curing process. Due to its strength and rigidity, steel formwork provides a stable structure that ensures the concrete is poured and cured in a controlled manner. During the concrete finishing stage, steel formwork allows for the smooth and even application of various finishing agents such as troweling, brushing, or spraying. The smooth surface of steel formwork allows for the easy application and manipulation of these agents, resulting in a uniform and aesthetically pleasing finish. Additionally, steel formwork is resistant to chemical reactions with concrete curing agents. Concrete curing agents are applied to the surface of freshly poured concrete to enhance its strength, durability, and appearance. These agents can include sealers, curing compounds, or coatings. Steel formwork does not chemically react with these substances, ensuring that they can be applied and absorbed by the concrete without any negative effects on the formwork material. Moreover, steel formwork is non-absorbent, meaning it does not absorb any moisture from the curing agents or the concrete itself. This characteristic is crucial during the curing process as it allows the concrete to retain its moisture content, ensuring proper hydration and strength development. The non-absorbent nature of steel formwork also prevents any potential damage or degradation that could occur if the formwork material were to absorb moisture and expand or corrode. In summary, steel formwork is an ideal material for handling concrete finishing and curing agents due to its strength, rigidity, non-reactive nature, and non-absorbent properties. It provides a stable structure for the application of finishing agents, while also allowing for proper curing and moisture retention in the concrete.

- Q: How does steel formwork affect the overall aesthetics of a concrete structure?

- The overall aesthetics of a concrete structure can be significantly influenced by the use of steel formwork. Utilizing steel as a material for formwork offers numerous advantages that directly contribute to enhancing the visual appeal of the final concrete product. To begin with, the concrete surface can achieve a smooth and uniform finish through the use of steel formwork. The rigid nature of steel ensures that there are no imperfections or irregularities present on the formwork, resulting in a flawless and visually pleasing concrete structure. This is particularly important for architectural elements that aim for a sleek and polished appearance. Additionally, steel formwork allows for greater flexibility in design. By utilizing steel, it becomes possible to create complex and intricate shapes, curves, and patterns that can transform a concrete structure into a piece of art. The malleability of steel enables architects and designers to push the boundaries of creativity, resulting in visually stunning concrete structures that stand out. Moreover, steel formwork offers excellent dimensional stability. It can withstand the pressure exerted by the fresh concrete, ensuring that the formwork maintains its shape and integrity throughout the pouring and curing process. This stability prevents any deformations or distortions in the concrete, resulting in a consistent and visually appealing appearance. Furthermore, steel formwork provides superior strength and durability. This allows for the construction of larger and taller concrete structures, which can be visually impressive and impactful. The robustness of steel formwork ensures that the concrete structure remains structurally sound and visually appealing for an extended period of time. In conclusion, steel formwork plays a crucial role in enhancing the aesthetics of a concrete structure. Its ability to provide a smooth finish, offer design flexibility, maintain dimensional stability, and provide strength contributes to the creation of visually pleasing and architecturally impressive buildings. Whether it is a high-rise tower, an intricate bridge, or an iconic landmark, steel formwork helps elevate the overall aesthetics and visual impact of the concrete structure.

- Q: What are the standard dimensions of steel formwork panels?

- The specific requirements and preferences of construction projects can cause variations in the standard dimensions of steel formwork panels. However, the industry commonly employs certain standard dimensions. Typically, steel formwork panels are obtainable in standard lengths ranging from 1 to 3 meters (3 to 10 feet), with a standard width of approximately 0.6 meters (2 feet). The thickness of the steel panels can also differ, but it is typically around 12 to 16 millimeters (0.5 to 0.6 inches). These dimensions are intended to create a robust and durable formwork system capable of withstanding the pressures and forces experienced during concrete pouring and curing. Moreover, these dimensions facilitate easy handling and transportation of the formwork panels at the construction site. It is worth noting that the dimensions of steel formwork panels can be tailored to meet the specific requirements of a project. This adaptability enables the construction of unique formwork systems capable of accommodating diverse shapes and sizes of concrete structures.

- Q: How does steel formwork handle formwork stripping?

- Formwork stripping is made easier with the use of steel formwork, which provides a sturdy and durable framework capable of withstanding the forces involved in its removal. Designed to be rigid and stable, steel formwork allows for efficient stripping once the concrete has cured. To remove the formwork panels or components from the concrete structure, the fasteners or connectors holding the formwork in place can be loosened. Steel formwork is commonly assembled with bolts, nuts, or other mechanical connectors, which can be easily undone during the stripping process. One advantage of using steel formwork is the smooth and clean surfaces it offers, minimizing the risk of concrete adhering to it while pouring and curing. This results in a simpler stripping process, as the concrete is less likely to stick to the steel surface. Moreover, the smooth surface allows for effortless cleaning and maintenance, ensuring its longevity and reusability. Additionally, steel formwork is renowned for its high strength and ability to bear heavy loads, allowing it to support the weight of the concrete during pouring and curing. This strength is also beneficial during the stripping process, as the steel formwork can withstand the pressure and forces involved without deforming or collapsing. Overall, steel formwork proves to be a reliable and efficient solution for formwork stripping. Its strength, durability, and user-friendliness make it a popular choice in construction projects that require quick and safe removal of formwork.

- Q: How does steel formwork contribute to the overall strength of a structure?

- Using steel panels and frames, steel formwork is a construction technique employed to create temporary molds for pouring concrete. This method offers several advantages over traditional wooden formwork, particularly in terms of strengthening a structure. Firstly, steel formwork boasts exceptional durability and resistance to wear and tear. Steel is a sturdy material capable of withstanding heavy loads and extreme weather conditions. Unlike wooden formwork, it does not warp, crack, or deteriorate over time, ensuring the structure's strength and integrity are maintained for an extended period. Furthermore, steel formwork provides superior dimensional stability compared to other materials. The precision fabrication of steel panels and frames guarantees accurate measurements and consistent shapes. This precision allows for a more even distribution of concrete, resulting in a stronger structure with reduced cracks or weaknesses. Moreover, steel formwork allows for greater flexibility in design and construction. The strength of steel permits the creation of intricate and complex structures that may not be achievable with alternative formwork materials. The versatility of steel formwork enables engineers to design structures with unique shapes and configurations, ultimately enhancing their overall strength and load-bearing capacity. Additionally, steel formwork contributes to the overall strength of a structure by offering excellent support and reinforcement during the concrete pouring process. Acting as a framework, the steel panels and frames hold the concrete in place until it solidifies and gains strength. This ensures proper and optimal curing of the concrete, resulting in a structurally sound and resilient structure. In conclusion, steel formwork plays a vital role in enhancing the overall strength of a structure. Its durability, dimensional stability, flexibility in design, and support during the concrete pouring process all contribute to creating a robust and long-lasting structure. By choosing steel formwork, construction projects can achieve higher levels of strength, durability, and structural integrity.

- Q: How does steel formwork handle different concrete setting time requirements?

- Steel formwork is highly versatile and can easily accommodate different concrete setting time requirements. It provides a rigid and sturdy framework that supports the concrete during the setting process. The steel formwork allows for precise shaping and molding of the concrete, enabling it to take various forms and designs. Additionally, steel formwork offers adjustable features, such as adjustable joints and connectors, which allow for quick assembly and disassembly, making it efficient in meeting different concrete setting time requirements. Overall, steel formwork provides a reliable and adaptable solution for handling different concrete setting time requirements.

- Q: Can steel formwork be used in areas with high wind loads?

- Yes, steel formwork can be used in areas with high wind loads. Steel is a strong and durable material that can withstand the forces exerted by high winds. It provides stability and structural integrity to the formwork system, ensuring that it remains secure even in challenging weather conditions.

Send your message to us

Tabel Formwork system for Formwork and Scaffolding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords