Tabel Formwork for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

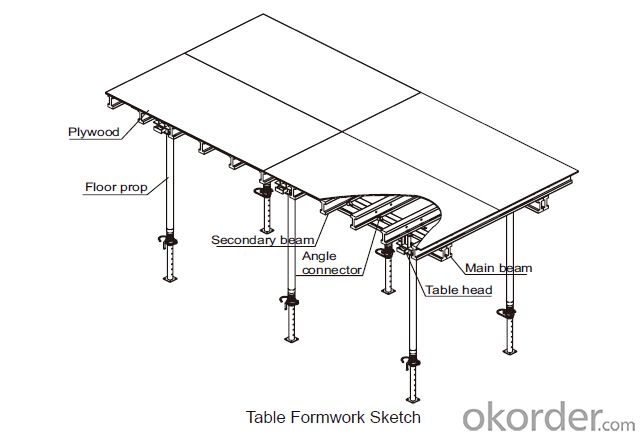

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel formwork be used for both horizontal and vertical concrete placements?

- Yes, steel formwork can be used for both horizontal and vertical concrete placements. Steel formwork provides a strong and durable structure that can withstand the pressure exerted by concrete during pouring and curing processes. It is versatile and can be easily assembled and disassembled, making it suitable for various construction applications.

- Q: Can steel formwork be used for hotel construction projects?

- Yes, steel formwork can be used for hotel construction projects. Steel formwork is a versatile and durable solution for constructing concrete structures, including hotels. It offers several advantages such as high strength, durability, and reusability. Steel formwork is capable of withstanding the pressure exerted by wet concrete and can be easily assembled and dismantled, making it suitable for use in various construction projects, including hotels. Additionally, steel formwork provides a smooth and accurate finish to concrete structures, ensuring high-quality construction.

- Q: Can steel formwork be used for architectural concrete slabs with embedded elements?

- Yes, steel formwork can be used for architectural concrete slabs with embedded elements. Steel formwork provides the necessary strength and durability to support the weight of the concrete and any embedded elements. It allows for precise shaping and detailing, ensuring the desired architectural design is achieved. Additionally, steel formwork can be easily re-used, making it a cost-effective option for such applications.

- Q: Are there any environmental considerations when using steel formwork?

- Yes, there are several environmental considerations when using steel formwork in construction projects. Firstly, steel production is known to have a significant carbon footprint. The extraction and processing of raw materials for steel production, such as iron ore and coal, contribute to greenhouse gas emissions. Additionally, the manufacturing process itself requires a large amount of energy, further contributing to carbon emissions. Moreover, steel formwork systems often require a significant amount of transportation, which adds to the environmental impact. The transportation of heavy steel panels and other components can result in increased fuel consumption and emissions, especially if long distances are involved. Furthermore, steel formwork is typically non-renewable and non-recyclable. Once it reaches the end of its lifespan, it often ends up in landfills, contributing to waste accumulation and environmental pollution. However, it is worth noting that steel formwork has some environmental advantages when compared to other formwork materials. For example, steel formwork can be reused multiple times, reducing the need for new materials and minimizing waste generation. Its durability and strength also contribute to longer lifespan and less frequent replacements, reducing overall resource consumption. To mitigate the environmental impact of using steel formwork, various measures can be taken. These include optimizing transportation routes to reduce fuel consumption, implementing energy-efficient manufacturing processes, and promoting the recycling of steel formwork components at the end of their life. Additionally, exploring alternative formwork materials such as recycled or sustainable materials can also help reduce environmental considerations associated with steel formwork usage.

- Q: What are the fire resistance properties of steel formwork?

- Steel formwork has excellent fire resistance properties due to its high melting point and low thermal conductivity. It is able to withstand high temperatures for extended periods of time without losing its structural integrity, making it a safe and reliable choice for construction projects in fire-prone areas.

- Q: Can steel formwork be used for both monolithic and composite construction?

- Yes, steel formwork can be used for both monolithic and composite construction.

- Q: How does steel formwork accommodate for different concrete pouring heights?

- Steel formwork offers versatility and adjustability, making it suitable for accommodating various concrete pouring heights. The system comprises interlocking steel panels that can be arranged in different configurations, enabling the creation of custom formwork tailored to the specific requirements of each construction project. To accommodate different concrete pouring heights, steel formwork utilizes adjustable props or supports. These props can be extended or retracted to achieve the desired elevation, providing the necessary support and stability for the formwork. By altering the height of the props, the formwork can easily adapt to different pouring heights. Moreover, steel formwork often incorporates adjustable brackets or clamps that can be moved along the vertical bars of the system. These brackets allow for the vertical positioning of the formwork panels, enabling them to be adjusted to the desired height for concrete pouring. Additionally, steel formwork systems typically offer a wide range of panel sizes that can be interchanged and combined to achieve the desired height. This flexibility facilitates the construction of formwork precisely matching the required pouring height, eliminating the need for extensive modifications or customizations. In summary, the adjustable features of steel formwork, including props, brackets, and interchangeable panels, make it effortless to accommodate different concrete pouring heights. This adaptability not only ensures efficient and accurate construction of concrete structures but also saves time and reduces labor costs on construction sites.

- Q: What are the different safety features incorporated in steel formwork systems?

- Workers' protection and the overall success of construction projects are ensured by steel formwork systems, which are equipped with numerous safety features. These features include: 1. Robust Construction: Steel formwork systems are constructed using high-quality steel materials, providing strength and stability. This strong construction reduces the risk of collapse or structural failure, ensuring the safety of workers. 2. Adjustable Support Systems: Props and jacks are incorporated into steel formwork systems to allow for precise adjustment and leveling. This ensures stability and prevents the formwork from shifting or collapsing. 3. Guardrails and Toe Boards: Standard safety features of steel formwork systems include guardrails and toe boards. These prevent workers from falling off the edges of the formwork, reducing the risk of accidents and injuries at height. 4. Non-Slip Surfaces: To enhance safety, steel formwork systems often have non-slip surfaces. These surfaces provide better traction and reduce the likelihood of workers slipping or falling, especially in wet or slippery conditions. 5. Safety Accessories: Many steel formwork systems come with additional safety accessories, such as safety nets, harnesses, and personal protective equipment (PPE). These accessories provide further protection for workers, preventing falls and ensuring compliance with safety regulations. 6. Easy Assembly and Dismantling: Steel formwork systems are designed for easy assembly and dismantling, minimizing the time workers spend at height. This reduces the risk of accidents during construction and promotes efficient workflow. 7. Fire Resistance: Steel formwork systems are often fire-resistant or fire-retardant, increasing safety in case of fire emergencies. This feature helps to prevent the rapid spread of fire and provides additional time for evacuation or firefighting. 8. High Load-Bearing Capacity: Steel formwork systems are engineered to have a high load-bearing capacity, allowing them to support heavy concrete loads. This ensures that the formwork can withstand the weight without deformation or failure, enhancing safety during construction. In conclusion, steel formwork systems prioritize worker safety and contribute to a safer working environment through their sturdy construction, adjustable support systems, guardrails, non-slip surfaces, safety accessories, easy assembly and dismantling, fire resistance, and high load-bearing capacity.

- Q: How does steel formwork compare to timber formwork in terms of cost?

- Steel formwork generally tends to be more expensive than timber formwork in terms of upfront costs. This is primarily due to the higher cost of steel as compared to timber. Additionally, steel formwork often requires specialized equipment and skilled labor for assembly and disassembly, which can add to the overall cost. However, it is important to consider the long-term benefits and cost-effectiveness of steel formwork. While timber formwork may have a lower initial cost, it is more susceptible to wear and tear, especially in harsh weather conditions or when used repeatedly. Steel formwork, on the other hand, is highly durable and can be used for multiple construction projects, making it a cost-effective choice in the long run. Moreover, steel formwork offers greater precision and accuracy, resulting in better quality finishes and reduced rework. It also allows for faster construction due to its ease of assembly and disassembly, which can lead to significant time and labor savings, ultimately offsetting the higher upfront cost. In summary, while steel formwork may be more expensive initially, it offers durability, reusability, and higher productivity, making it a more cost-effective option in the long term compared to timber formwork.

- Q: Can steel formwork be used for complex geometric designs?

- Complex geometric designs can indeed be achieved using steel formwork. Steel, being a versatile material, can be effortlessly shaped and molded into diverse intricate forms, thereby making it well-suited for such designs. By employing steel formwork, construction can be carried out with utmost precision and accuracy, guaranteeing the attainment of the desired shape and dimensions. Moreover, the robustness and longevity of steel render it capable of withstanding the weight and pressure exerted during the pouring of concrete, thus establishing steel formwork as a dependable option for the creation of complex geometric designs in construction endeavors.

Send your message to us

Tabel Formwork for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords