Tabel Formwork for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

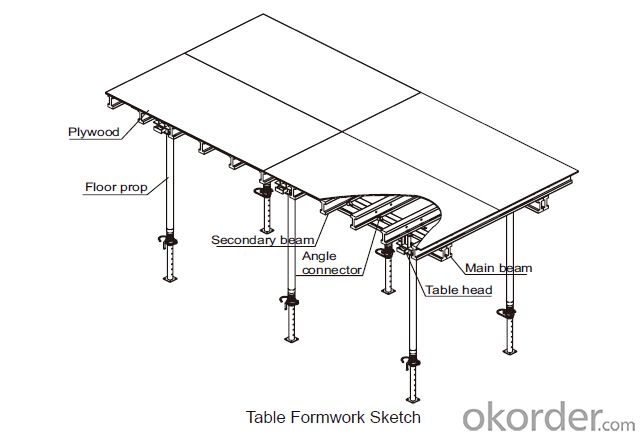

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: What are the different types of form ties used in steel formwork?

- Steel formwork utilizes various types of form ties, each serving specific purposes and meeting distinct requirements. 1. Coil Ties: Flexibility and effortless installation and removal are provided by coil ties, which feature a coil rod with two to four coils. These ties are commonly utilized in lighter applications where lower pressure is anticipated. 2. Flat Ties: Constructed from steel, flat ties possess wide, flat plates on both ends. Their purpose is to connect opposing wall forms, ensuring stability and preventing bulging or spreading caused by concrete pressure. 3. She-Bolt Ties: She-bolt ties consist of a she-bolt attached to one end of a threaded rod. These ties secure wall forms together, and the threaded rod allows for easy formwork adjustment. 4. Snap Ties: Snap ties are a popular choice for swift and efficient formwork installation. They consist of a metal rod with a button-like head on one end and a wedge on the other. By inserting the button head into the formwork and driving the wedge into the button head using a hammer, a robust connection is created. 5. Cone Ties: Similar to snap ties, cone ties possess a cone-shaped head instead of a button head. The cone head is inserted into the formwork, and a metal wedge is driven into the cone, securing the formwork. 6. Waler Ties: Waler ties connect horizontal waler beams with vertical formwork members, enhancing the strength and stability of the formwork system. 7. Loop Ties: Made of steel wire, loop ties feature loops on both ends. They are employed to fasten wall forms together and can be effortlessly removed once the concrete has cured. 8. Pin and Wedge Ties: Pin and wedge ties comprise a pin and a wedge. The pin is inserted into the formwork, and the wedge is driven into the pin, creating a tight and secure connection. These examples represent only a fraction of the form ties available for steel formwork. The selection of a tie depends on factors such as construction type, desired strength, ease of installation, and specific project requirements.

- Q: How does steel formwork affect the schedule of concrete pouring?

- The schedule of concrete pouring can be significantly influenced by steel formwork. A major advantage of using steel formwork is its strength and durability, which enables faster construction progress. Unlike traditional wooden formwork, steel formwork can be reused multiple times, resulting in shorter construction cycles and faster completion times. Moreover, the use of steel formwork facilitates a quicker assembly and disassembly process. It requires less time to set up compared to wooden formwork since it usually comes prefabricated or in standard sizes that can be easily assembled on site. This speedy assembly process reduces the time required for formwork installation, initiating concrete pouring sooner. Additionally, steel formwork provides a smooth and uniform surface finish to the concrete. This eliminates the need for plastering or additional finishing work, saving time and effort. The smooth surface also reduces the curing time of the concrete, as it allows for more efficient evaporation of moisture. Furthermore, steel formwork is renowned for its superior strength and stability. This allows for a higher rate of concrete pouring, as it can withstand the pressure exerted by the wet concrete without deforming or collapsing. With steel formwork, larger concrete sections can be poured simultaneously, reducing the number of pours and thus saving time. Nevertheless, it is crucial to note that careful planning and coordination are required for steel formwork to ensure a seamless workflow. The availability of steel formwork materials and equipment, as well as skilled labor, must be considered during the project scheduling process. Any delays in the procurement or fabrication of steel formwork can impact the schedule for concrete pouring. In conclusion, steel formwork positively impacts the schedule of concrete pouring by reducing construction time, providing a smooth surface finish, allowing for faster assembly and disassembly, and enabling the pouring of larger concrete sections at once. However, proper planning and coordination are crucial to maximize the benefits of steel formwork and avoid potential delays.

- Q: What are the different safety guidelines for dismantling steel formwork?

- When dismantling steel formwork, there are several important safety guidelines that should be followed to ensure the protection of workers and prevent accidents. These guidelines include: 1. Personal Protective Equipment (PPE): All workers involved in the dismantling process should wear appropriate PPE, including safety goggles or glasses, gloves, hard hats, and steel-toed boots. This will protect them from potential hazards such as falling debris or sharp edges. 2. Training and Competency: Only trained and competent individuals should be assigned to dismantle steel formwork. They should have a good understanding of the dismantling process and be aware of the potential risks involved. 3. Safe Work Area: Before starting the dismantling process, the work area should be properly prepared. This involves clearing any obstructions or hazards, ensuring a stable and level ground, and marking off the area to prevent unauthorized access. 4. Tools and Equipment: Workers should use appropriate tools and equipment for dismantling steel formwork. This may include wrenches, hammers, cutting tools, and lifting equipment. Tools should be inspected regularly for any damage or defects and replaced if necessary. 5. Structural Stability: Before dismantling any part of the formwork, workers should ensure that the structure is stable and secure. This may involve using temporary supports or bracing to prevent any collapse or movement during the dismantling process. 6. Sequential Dismantling: Steel formwork should be dismantled in a sequential manner, starting from the top and working downwards. This helps maintain the stability of the structure and minimizes the risk of uncontrolled collapses. 7. Controlled Lowering: When dismantling larger steel formwork components, such as panels or beams, they should be lowered in a controlled manner using appropriate lifting equipment. This prevents sudden movements or drops that could cause injuries or damage. 8. Communication and Coordination: Clear communication and coordination between workers involved in the dismantling process is crucial to ensure everyone's safety. This includes using hand signals, verbal communication, and following a pre-determined plan or procedure. 9. Regular Inspection: Regular inspection of the steel formwork during the dismantling process is important to identify any signs of damage, corrosion, or structural defects. Any issues should be reported immediately and appropriate actions taken to address them. 10. Emergency Procedures: Workers should be familiar with emergency procedures in case of accidents or unexpected events. This includes knowing the location of emergency exits, fire extinguishers, and first aid kits, as well as understanding how to respond to incidents such as a collapse or injury. By following these safety guidelines, the risk of accidents and injuries can be significantly reduced during the dismantling of steel formwork. It is important to prioritize the safety of workers and ensure that proper precautions are taken at all times.

- Q: PVC building template introduction

- PVC construction template turnover number can reach more than 30 times, but also recycling. The temperature range is large, the specification is strong, can be seen, drill, easy to use. The smoothness and smoothness of the surface of the template exceed the technical requirements of the existing clear water concrete formwork, and the utility model has the functions of fire resistance, corrosion resistance, water resistance and chemical corrosion resistance. Can meet the demands of building formwork of various cuboids and cubes, L shape, U shape requirements.PVC building template is to insist on processing experience digest and absorb the European advanced equipment manufacturing technology and half on advanced products and technology, composite material formed by extruding the high temperature of 200 DEG C.

- Q: How does steel formwork affect the overall material wastage in construction?

- Steel formwork can significantly reduce material wastage in construction. Unlike traditional timber formwork, steel formwork is reusable and durable, which means it can be used multiple times for different construction projects. This reduces the need for constantly buying and disposing of new formwork materials, resulting in less overall material wastage. Additionally, steel formwork provides better dimensional accuracy and stability, minimizing errors and the need for rework, further reducing material wastage.

- Q: Can steel formwork be used for suspended slabs?

- Yes, steel formwork can be used for suspended slabs. Steel formwork is a versatile and strong material that can provide the necessary support and shape for suspended slabs. It offers advantages such as durability, reusability, and flexibility in design. Steel formwork can be easily assembled and disassembled, making it suitable for suspended slab construction where formwork needs to be moved or adjusted. Additionally, steel formwork provides a smooth and finished surface for the slab, reducing the need for additional finishing work.

- Q: Can steel formwork be used in curved or irregular structures?

- Curved or irregular structures can indeed make use of steel formwork. This type of formwork grants great flexibility and can be effortlessly modified to generate different shapes and curves. It presents the benefit of withstanding substantial pressure, enabling the efficient and accurate construction of curved or irregular structures. Steel formwork is especially appropriate for intricate architectural designs and structures necessitating distinctive shapes, like curved walls, columns, and beams. Furthermore, the durability and strength of steel render it a dependable option for such applications, guaranteeing the stability and longevity of the structure.

- Q: Can steel formwork be used for both standard and non-standard concrete sections?

- Steel formwork is suitable for both standard and non-standard concrete sections. It is a highly versatile option that can be customized to fit different shapes and sizes of concrete sections. Construction projects that involve unique or complex concrete structures often utilize steel formwork. It offers flexibility in creating non-standard shapes like curves, slopes, and irregular geometries. Moreover, steel formwork provides excellent strength and durability, making it perfect for both standard and non-standard concrete sections that require high load-bearing capacity. Its reusability also contributes to its cost-effectiveness, making it a viable choice for projects with varying concrete sections. In summary, steel formwork is the ideal solution for construction projects that require the flexibility and strength to accommodate both standard and non-standard concrete sections.

- Q: What are the different types of steel used for formwork construction?

- There are several types of steel commonly used for formwork construction, including mild steel, high-strength low-alloy (HSLA) steel, and reinforced steel. These different types of steel offer varying levels of strength and durability, allowing for the construction of formwork that can withstand the pressures and forces exerted during the concrete pouring process.

- Q: Can steel formwork be used in bridge construction?

- Yes, steel formwork can be used in bridge construction. Steel formwork is a durable and versatile option that can withstand the heavy loads and harsh environmental conditions associated with bridge construction. It offers the required strength and stability to support the concrete during the construction process, ensuring the bridge's structural integrity. Additionally, steel formwork can be easily assembled, disassembled, and reused, making it a cost-effective choice for bridge construction projects.

Send your message to us

Tabel Formwork for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords