Tabel formwork for Formwork and Scaffolding Systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

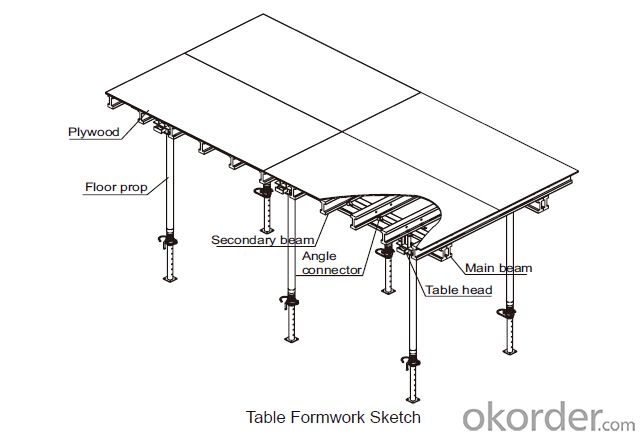

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: What are the common challenges associated with steel formwork?

- Construction projects face several common challenges when it comes to steel formwork. One of the main obstacles is the high initial cost associated with purchasing or renting steel formwork compared to other materials like wood or plastic. Although steel formwork is more durable and has a longer lifespan, smaller construction companies or projects with limited budgets may find the upfront investment prohibitive. Another issue is the weight and handling of steel formwork. Due to its heaviness, transporting, assembling, and dismantling steel formwork on-site can be challenging. This may necessitate additional labor and equipment, leading to increased construction costs. Proper installation and alignment of steel formwork also require skilled labor. Achieving the desired dimensions and finishes of concrete structures relies heavily on the accuracy and precision of the formwork. Mistakes or misalignments during setup can result in costly rework or compromised structural integrity. Maintenance and storage of steel formwork pose their own challenges. Regular cleaning and treatment are necessary to prevent rust and corrosion, particularly in humid or coastal areas. Sufficient storage space is also essential for protecting the formwork from external elements when not in use. Lastly, customization and adaptability can prove challenging with steel formwork. Unlike wood formwork, which can be cut and shaped on-site, steel formwork requires prefabrication and customization before use. Any changes in design or dimensions during the construction process may require additional time and cost to modify or replace the steel formwork components. Despite these challenges, steel formwork offers numerous advantages, including durability, reusability, and high-quality finishes. By implementing proper planning, training, and maintenance, these challenges can be effectively managed to ensure the success of construction projects.

- Q: What are the common safety precautions when working with steel formwork?

- Some common safety precautions when working with steel formwork include wearing appropriate personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and steel-toe boots. It is also important to ensure that the formwork is properly secured and braced to prevent collapse or movement. Regular inspections should be conducted to identify any defects or weaknesses in the formwork. Additionally, workers should receive proper training on how to safely assemble, disassemble, and handle the steel formwork to avoid any potential injuries.

- Q: How does steel formwork prevent concrete mixture separation during pouring?

- In construction projects, steel formwork is employed to create a temporary structure that securely holds the concrete in position until it solidifies and becomes rigid. A significant advantage of utilizing steel formwork is its ability to prevent the concrete mixture from disintegrating while it is being poured. The steel formwork is meticulously designed and assembled to establish a tight enclosure for the concrete, guaranteeing that it maintains its intended shape and texture. It consists of firmly fastened steel panels and frames, which combine to form a sturdy structure. When the concrete mixture is poured into the steel formwork, it is effectively restrained by the formwork walls itself. The steel panels and frames offer a smooth and uniform surface onto which the concrete can be poured, effectively averting any separation or division within the mixture. Moreover, the steel formwork is purposefully constructed with accurately aligned joints and connections, which further prevents any leakage or permeation of the concrete mixture. This ensures the integrity of the concrete, preventing it from breaking down into its constituent materials such as aggregates, cement, and water. Additionally, the steel formwork possesses the capacity to withstand the pressure exerted by the weight of the concrete. This successfully averts any deformation or displacement of the formwork during the pouring process, as such movements could potentially lead to the separation or shifting of the concrete. All in all, the utilization of steel formwork provides a robust and steady structure that effectively prevents the concrete mixture from separating during pouring. It ensures the concrete maintains its desired form and consistency, ultimately resulting in a finished product that is of high quality and durability.

- Q: Can steel formwork be used for temporary structures?

- Yes, steel formwork can be used for temporary structures. Steel formwork is durable, strong, and can withstand heavy loads, making it suitable for temporary structures such as scaffolding, shoring, and temporary supports. Its versatility and reusability make it a popular choice in construction projects requiring temporary structures.

- Q: What are the different types of steel formwork systems available in the market?

- There are several different types of steel formwork systems available in the market, including traditional steel formwork, modular steel formwork, and panelized steel formwork. Traditional steel formwork consists of steel plates or frames that are assembled on-site to create the desired formwork shape. Modular steel formwork is pre-engineered and consists of standardized panels that can be easily assembled and reused. Panelized steel formwork is similar to modular steel formwork but consists of large panels that are interconnected to create the desired formwork shape.

- Q: What are the common safety measures to be followed when using steel formwork?

- To ensure the safety of workers and the successful completion of construction projects using steel formwork, it is important to adhere to several safety measures. These measures include: 1. Proper training and education: All workers involved in the use of steel formwork should receive comprehensive training on its installation, usage, and dismantling. They must be knowledgeable about potential hazards and how to mitigate them. 2. Inspection and maintenance: Before utilizing steel formwork, it is crucial to thoroughly inspect it for any defects or damages. Any issues should be promptly addressed or the formwork should be replaced. Regular maintenance should also be performed to ensure its structural integrity. 3. Careful handling and storage: Steel formwork should be handled with caution to avoid injuries. It should be stored in a designated area, away from potential hazards or heavy machinery. 4. Use of personal protective equipment (PPE): To safeguard themselves from potential hazards or falling objects, workers should always wear appropriate PPE, such as safety helmets, safety goggles, gloves, and safety shoes. 5. Sufficient bracing and support: To prevent collapse or structural failure, steel formwork should be adequately braced and supported. This involves using the correct number and type of props or supports, as well as ensuring the formwork is level and plumb. 6. Secure and stable footing: Workers must have a secure and stable footing when working with steel formwork. This may necessitate the use of scaffolding or temporary platforms to provide a safe working surface. 7. Proper lifting techniques: When lifting or moving steel formwork, workers should employ correct lifting techniques to prevent strains or injuries. This may entail using lifting equipment, such as cranes or hoists, and ensuring an even distribution of the load. 8. Effective communication and coordination: Clear communication and coordination among workers is essential when utilizing steel formwork. This helps prevent accidents and ensures that everyone understands their roles and responsibilities. By adhering to these common safety measures, the risk of accidents or injuries when using steel formwork can be significantly reduced, resulting in a safer and more productive work environment.

- Q: Can steel formwork be used for high-rise construction projects?

- Indeed, high-rise construction projects can indeed utilize steel formwork. Renowned for its robustness and resilience, steel formwork is ideally suited for demanding tasks like high-rise construction. It furnishes exceptional steadiness and reinforcement to the concrete throughout the pouring and solidifying stages, guaranteeing the building's structural soundness. Moreover, steel formwork can be swiftly assembled and disassembled, making it highly efficient for constructing tall edifices that encompass multiple floors. Furthermore, its reusable characteristic facilitates long-term cost savings. In summary, steel formwork is an esteemed and widespread preference for high-rise construction endeavors.

- Q: What are the different types of formwork anchors used in steel formwork?

- Steel formwork commonly uses various types of formwork anchors to secure the formwork to the structure and ensure construction process stability and safety. Examples of these formwork anchors include: 1. Wedge Anchor: This anchor has a threaded rod with a wedge-shaped end. By inserting it into a pre-drilled hole in the concrete structure and tightening a nut on the threaded end, a strong grip is formed. It is commonly used to secure formwork to concrete walls or slabs. 2. Screw Anchor: Also known as self-tapping anchors, these anchors are designed for use in softer materials like wood or light-gauge steel. They have a threaded body that can be screwed into the material, providing a secure connection for the formwork. Screw anchors are popular for temporary formwork applications due to their easy installation and removal. 3. Hook Anchor: This hook-shaped anchor is typically embedded into the concrete structure during the pouring process. The formwork is then attached to the hook using bolts or fasteners, creating a strong and reliable connection. Hook anchors are commonly used in applications with high loads or lateral forces. 4. Swift Lift Anchor: Specifically designed for lifting and handling precast concrete elements, including steel formwork, these anchors are embedded into the structure during pouring. They provide a safe and efficient method for lifting and positioning the formwork. 5. Plate Anchor: Plate anchors consist of a flat plate with holes for bolts or fasteners. They are versatile and commonly used in steel formwork systems to secure the formwork to the structure. Plate anchors can be easily adjusted or relocated as needed. 6. Chemical Anchor: Chemical anchors are used when a strong and permanent connection is required. They consist of a resin or adhesive injected into a pre-drilled hole in the concrete structure. The steel formwork is then attached to the chemical anchor, creating a secure bond. Each type of formwork anchor has unique advantages and is suitable for different applications. Factors such as the type of structure, load requirements, and duration of use should be considered when selecting the appropriate anchor and ensuring proper installation for the safety and stability of the formwork system.

- Q: What are the considerations when designing steel formwork for underground structures?

- When designing steel formwork for underground structures, several considerations need to be taken into account. Firstly, the formwork should be sturdy and durable enough to withstand the pressure exerted by the surrounding soil. Underground structures often face significant lateral and vertical loads, so the formwork needs to be able to resist these forces without deforming or collapsing. Steel is an ideal material for this purpose due to its high strength and rigidity. Secondly, the formwork should be designed in a way that allows for easy installation and removal. Underground construction can be challenging due to limited access and confined working spaces. Therefore, the formwork system should be modular and easily adjustable to fit different shapes and sizes of underground structures. This would enable efficient construction and minimize the time and effort required for formwork installation and removal. Additionally, the formwork design should consider the ease of concrete pouring and subsequent curing. Proper consideration should be given to the placement of tie rods, formwork joints, and other structural elements to ensure that the concrete can flow smoothly and evenly throughout the structure. The formwork system should also incorporate adequate provisions for ventilation and drainage to prevent the accumulation of water or air pockets, which could compromise the structural integrity of the underground construction. Moreover, safety is a paramount consideration when designing steel formwork for underground structures. The formwork system should have appropriate safety features, such as guardrails and access platforms, to provide a secure working environment for the construction workers. The design should also consider the use of lifting and handling equipment to minimize manual handling and reduce the risk of accidents or injuries during formwork installation and dismantling. Lastly, the formwork design should take into account the project's budget and schedule constraints. Steel formwork can be more expensive than other types of formwork, so cost-effective design solutions should be explored without compromising safety and performance. Additionally, the formwork system should be designed for easy reusability, allowing for multiple applications and reducing the overall project costs. In conclusion, designing steel formwork for underground structures requires careful consideration of factors such as strength, durability, ease of installation, concrete pouring, safety, and cost-effectiveness. By addressing these considerations, designers can ensure the successful construction of underground structures that meet the project's requirements and withstand the challenges of underground environments.

- Q: Can steel formwork be used for precast concrete columns?

- Yes, steel formwork can be used for precast concrete columns. Steel formwork offers durability and strength, making it suitable for creating precise and complex shapes required for precast concrete columns. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for precast concrete column production.

Send your message to us

Tabel formwork for Formwork and Scaffolding Systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords