Steel Structure made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

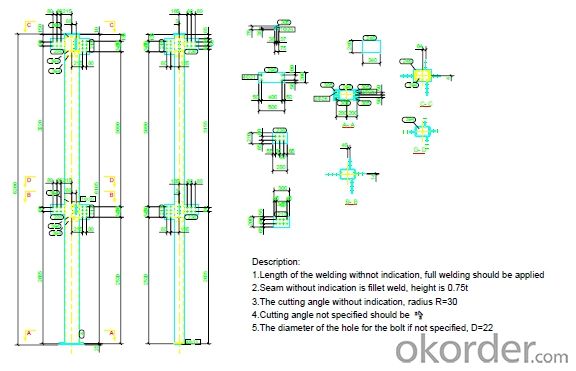

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

Inner Mongolia Shangdu Power Plant is the main source

of west-east power transmission project with total

incestment of 5137 million Yuan. 1,900 tons for the steel

structure of the project with maximum thickness 60mm-

75mm.

- Q: What are the key considerations for maintaining and inspecting steel structures?

- Some key considerations for maintaining and inspecting steel structures include regular inspections to identify any signs of corrosion, wear and tear, or structural damage. It is important to have a comprehensive maintenance plan in place that includes cleaning, repainting, and applying protective coatings to prevent corrosion. Regular inspections should also include checking for any loose connections, cracks, or deformations in the structure. Additionally, it is crucial to comply with relevant safety regulations and standards, and to have qualified professionals conduct the inspections and necessary repairs.

- Q: How are steel structures designed for resisting impact from vehicle collisions?

- Steel structures are designed to resist impact from vehicle collisions through various engineering principles and design techniques. The primary objective is to ensure the safety of both the occupants of the vehicle and the integrity of the structure itself. One of the most common methods used is incorporating energy-absorbing features into the design. This involves the use of specially designed steel members, such as crash barriers or guardrails, that are intended to deform and absorb the impact energy during a collision. By deforming and dissipating energy, these structures help to prevent or minimize damage to the main load-bearing components of the structure. Additionally, the design of steel structures for impact resistance often involves the use of advanced computer simulations and modeling techniques. These simulations allow engineers to analyze the impact forces and predict the behavior of the structure in a collision scenario. This helps in determining the optimal size, shape, and placement of energy-absorbing elements to ensure maximum protection. Furthermore, the choice of materials and the specific design of the steel members play a crucial role in enhancing the structure's ability to resist impact. High-strength steel alloys are commonly used, as they offer superior strength and toughness compared to conventional steel. This allows for the construction of lighter and more efficient structures that can withstand greater impact forces. In addition to the structural elements, other safety measures are also considered, such as the implementation of crash-tested barriers, the use of breakaway sign supports, and the placement of guardrails or barriers to redirect or contain the impact force. Overall, the design of steel structures for resisting impact from vehicle collisions involves a combination of energy absorption, advanced modeling techniques, material selection, and the implementation of additional safety features. By considering these factors, engineers can create robust and safe structures that are capable of withstanding the forces generated during a collision, protecting both the occupants and the structure itself.

- Q: How do steel structures perform in fire conditions?

- Steel structures generally perform well in fire conditions. Steel has a high melting point and excellent heat transfer properties, allowing it to retain its structural integrity for a longer duration during a fire. It does not contribute to the spread of fire or emit toxic fumes. However, prolonged exposure to high temperatures can weaken steel, causing it to deform or lose strength over time. Therefore, fire protection measures, such as fire-resistant coatings or fireproofing materials, are often necessary to enhance the fire performance of steel structures and ensure their safety in fire conditions.

- Q: What are the common methods of connecting steel components in a structure?

- There are several common methods used to connect steel components in a structure. These methods include welding, bolting, and riveting. Welding is one of the most commonly used methods and involves joining the steel components by melting the edges and fusing them together. This creates a strong and continuous connection. Welding can be done using various techniques such as arc welding, gas welding, or electric resistance welding. It is especially useful for connections that require high strength and load-bearing capacity. Bolting is another widely used method for connecting steel components. This involves using bolts, nuts, and washers to secure the components together. Bolting provides a flexible and reversible connection, making it suitable for structures that may require disassembly or modifications in the future. It also allows for easy inspection and maintenance of the connection. Riveting is an older method of connection, but it is still used in certain applications. It involves using rivets, which are cylindrical metal pins, to join the components. Rivets are inserted through pre-drilled holes in the components and then hammered or compressed to create a permanent connection. This method provides good structural integrity and can be useful in situations where high vibration or dynamic loads are present. In addition to these primary methods, other techniques such as adhesive bonding and mechanical connectors can also be employed to connect steel components in specific situations. Adhesive bonding involves using high-strength adhesives to join the components, while mechanical connectors utilize specialized fittings or connectors to create the connection. The choice of the connection method depends on various factors such as the structural requirements, load capacity, design considerations, and project constraints. Each method has its advantages and limitations, and it is essential to select the most appropriate method based on the specific needs of the structure.

- Q: How are steel structures designed to accommodate expansion and contraction?

- Steel structures are designed to accommodate expansion and contraction through the use of expansion joints and flexible connections. Expansion joints are strategically placed gaps or spaces in the structure that allow for the movement of the steel members without causing damage or stress. Additionally, flexible connections, such as slip-critical connections or bolted connections with oversized holes, are used to allow for movement and prevent the transfer of stress between different parts of the structure. These design considerations ensure that the steel structure can safely expand and contract due to temperature changes or other factors without compromising its integrity.

- Q: What are the factors to consider when selecting steel for a structure?

- When selecting steel for a structure, there are several factors to consider. These include the desired strength and durability of the steel, the anticipated load or weight that the structure will bear, the environmental conditions the structure will be exposed to (such as moisture, temperature variations, or corrosive elements), the required fire resistance, as well as the cost and availability of the steel. Additionally, factors like the design flexibility, ease of fabrication, and the potential for future modifications or expansions should also be taken into account.

- Q: What are the different types of steel mezzanine flooring?

- Some of the different types of steel mezzanine flooring include open grid, solid steel, and composite steel. Open grid flooring consists of a series of metal bars or grating that allow for ventilation and light to pass through. Solid steel flooring is a flat, solid surface that provides a sturdy and durable platform. Composite steel flooring combines the benefits of both open grid and solid steel, with a solid top surface and open grid design underneath for ventilation and light transmission.

- Q: How are steel structures designed for efficient use of natural resources?

- Steel structures are designed for efficient use of natural resources through various measures. Firstly, the design process focuses on using the optimal amount of steel, minimizing waste and ensuring that the structure is lightweight yet strong enough to withstand the intended loads. Additionally, the use of advanced computer-aided design (CAD) software helps to optimize the design, resulting in less material consumption. Furthermore, steel structures are often designed with the ability to be dismantled and reused, reducing the demand for new materials. Finally, steel is a highly recyclable material, and the design of steel structures often incorporates the use of recycled steel, further reducing the need for virgin resources.

- Q: How are steel beams designed and sized?

- Steel beams are designed and sized using various factors such as the span length, load requirements, and the specific structural design codes and standards. Structural engineers analyze the loadings on the beam, including dead loads (weight of the beam itself), live loads (loads applied to the beam during its use), and other factors like wind and seismic loads. With this information, engineers use mathematical calculations and computer modeling to determine the appropriate size, shape, and reinforcement needed for the steel beam to safely support the anticipated loads.

- Q: What are the different types of steel beams used in steel structures?

- There are several types of steel beams commonly used in steel structures, including I-beams, H-beams, and C-beams. I-beams, also known as universal beams, have an "I" shape and are widely used due to their versatility and strength. H-beams, also known as wide flange beams, have a wider shape and are commonly used for larger structures and heavy load-bearing applications. C-beams, also known as channel beams, have a C-shaped cross-section and are often used for smaller structural elements and support systems. These different types of steel beams offer unique characteristics and are selected based on the specific requirements of the steel structure.

Send your message to us

Steel Structure made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords