Bead Blasted Stainless Steel

Bead Blasted Stainless Steel Related Searches

Stainless Steel Beads Sandblasted Stainless Steel Stainless Steel Bead Chain Bending Stainless Steel Brushed Stainless Steel Welded Stainless Steel Bleached Stainless Steel Weld Stainless Steel Scratched Stainless Steel Colored Stainless Steel Brazing Stainless Steel Bleach Stainless Steel Quilted Stainless Steel Blender Stainless Steel Bread Box Stainless Steel Stainless Steel Weld Clad Stainless Steel Kitchen Aid Stainless Steel Stainless Steel Jewellery Patinated Stainless Steel Annealed Stainless Steel Anodized Stainless Steel Tarnished Stainless Steel Stainless Steel Jewelery Painted Stainless Steel Flask Stainless Steel Stainless Steel Blade Stainless Steel Lid 3d Printed Stainless Steel Metal Stainless SteelBead Blasted Stainless Steel Supplier & Manufacturer from China

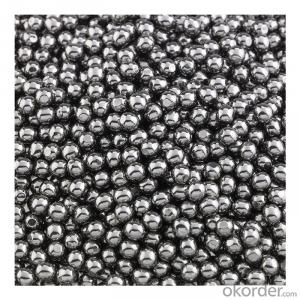

Bead Blasted Stainless Steel is a type of stainless steel that has undergone a specific surface treatment process called bead blasting. This process involves the use of small, abrasive particles that are projected onto the surface of the stainless steel, resulting in a uniform, matte finish that is both visually appealing and functional. The bead blasting process not only enhances the aesthetic appeal of the stainless steel but also improves its resistance to corrosion and wear, making it a popular choice for various applications.The Bead Blasted Stainless Steel is widely used in a range of industries, including construction, automotive, aerospace, and food processing. Its unique finish and enhanced durability make it ideal for applications where both appearance and performance are critical. For instance, in the construction industry, bead blasted stainless steel is often used for exterior cladding and architectural features, while in the automotive sector, it is employed in the manufacturing of car parts and components that require a high level of resistance to wear and tear.

As a leading wholesale supplier, Okorder.com offers a vast inventory of Bead Blasted Stainless Steel products to cater to the diverse needs of its customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Bead Blasted Stainless Steel it supplies meets the highest industry standards. This extensive inventory allows customers to find the exact specifications and quantities they require, making Okorder.com a one-stop-shop for all their Bead Blasted Stainless Steel needs.

Hot Products