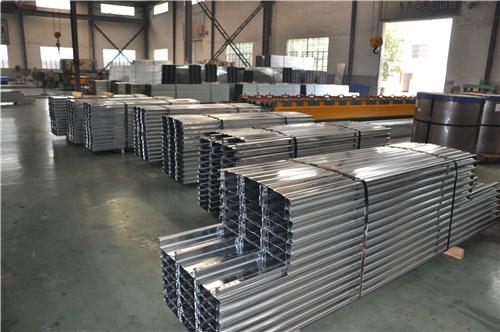

C Channel Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

In architecture, structural engineering or building, a purlin (or historically purline, purloyne, purling, perling) is any longitudinal, horizontal, structural member in a roof except a type of framing with what is called a crown plate. In traditional timber framing there are three basic types of purlin: purlin plate, principal purlin and common purlin.

Description

1)Price:FOB $500-650

2)Material:Q195-Q420,Q195,Q215,Q235,Q345

3)Certification:ISO9001, SGS, BV

4)Payment term:TT,L/C

Specofications

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

- Q: What is the difference between steel structure, light steel workshop, color steel room and movable room?

- Color steel plate movable room is mainly made of frame, colorful steel plate as the enclosure of movable room (movable board room). The color steel movable room is a simple house made of some standard plates. The utility model has the advantages of flexible assembly and convenient transportation. The utility model is used in temporary facilities. Such as site activities room, movable room, booth, newsstand, office, color steel plate wall, partition wall, color steel plate, roof layer and so on.

- Q: What are the different types of steel pedestrian bridges?

- There are several different types of steel pedestrian bridges, including truss bridges, beam bridges, suspension bridges, and cable-stayed bridges. Each type has its own unique design and structural characteristics.

- Q: How do steel structures contribute to the overall sustainability of a building?

- There are several ways in which steel structures enhance the overall sustainability of a building. To begin with, steel possesses exceptional durability and a long lifespan. Consequently, steel structures necessitate less maintenance and replacement over time in comparison to alternative building materials. This durability diminishes the requirement for regular repairs and renovations, thereby decreasing the overall environmental impact of the building. Furthermore, steel is a recyclable material. At the conclusion of a building's life cycle, it is effortless to dismantle steel structures and recycle the steel for alternative purposes. This reduces the quantity of waste generated during the demolition process and minimizes the depletion of natural resources. Moreover, steel structures present design flexibility, permitting efficient utilization of space and the capability to adapt to changing needs. This flexibility implies that buildings can be easily modified or expanded without extensive demolition or reconstruction. Consequently, construction waste is reduced, contributing to the overall sustainability of the building. Additionally, steel is a lightweight material when compared to other construction materials like concrete. This lightweight characteristic facilitates easier transportation and assembly, resulting in reduced energy consumption during construction and minimized carbon emissions during transportation. Lastly, steel structures possess high resistance to fire, earthquakes, and other natural disasters. By providing a secure and safe environment, steel structures increase a building's longevity and reduce the necessity for reconstruction following a disaster. This resilience minimizes the environmental impact of rebuilding and decreases the risk to human life, thus contributing to the overall sustainability of the building. In conclusion, steel structures enhance the overall sustainability of a building due to their durability, recyclability, design flexibility, lightweight nature, and resilience. By selecting steel as a building material, we can construct structures that are not only environmentally friendly but also cost-effective and safe for occupants.

- Q: What are the design considerations for steel transportation infrastructure?

- When it comes to designing steel transportation infrastructure, there are several important factors that need to be taken into consideration. These factors include: 1. Structural Integrity: It is crucial to design steel transportation infrastructure, such as bridges and overpasses, in a way that can withstand the various loads and stresses placed upon them. This includes considering factors such as vehicle weight, wind forces, seismic activity, and potential impacts from accidents or natural disasters. The design must ensure that the structure remains stable and safe throughout its lifespan. 2. Durability and Maintenance: Steel structures in transportation infrastructure are exposed to different environmental conditions, including moisture, temperature changes, and corrosive agents like salt and chemicals used for de-icing. Designers must choose appropriate materials and protective coatings to ensure that the structure lasts a long time and requires minimal maintenance and repairs. 3. Cost-effectiveness: Design considerations for steel transportation infrastructure should also take into account cost-effectiveness. This involves optimizing the use of materials, minimizing construction and maintenance costs, and considering the overall life-cycle costs of the structure. By balancing initial construction costs with long-term maintenance expenses, designers can create cost-effective solutions. 4. Aesthetics and Urban Integration: Steel transportation infrastructure often has a significant visual impact on the urban landscape. It is important to consider factors such as architectural design, visual impact, and how well the structure blends in with the surrounding environment. The structure should harmonize with its surroundings and enhance the aesthetics of the area. 5. Environmental Impact: Designers should also consider the environmental impact of steel transportation infrastructure. This includes minimizing the use of non-renewable resources, reducing carbon emissions during construction, and considering the potential impact on natural habitats or water bodies. Sustainable design practices, such as using recycled steel or incorporating green infrastructure elements, can help minimize the environmental footprint. 6. Safety and Accessibility: Design considerations should prioritize the safety of users and ensure accessibility for all individuals, including pedestrians, bicyclists, and people with disabilities. This involves incorporating proper signage, lighting, and barrier systems, as well as considering emergency evacuation routes and safety features in the design. In conclusion, designing steel transportation infrastructure requires careful consideration of factors such as structural integrity, durability, cost-effectiveness, aesthetics, environmental impact, safety, and accessibility. By addressing these factors, engineers and designers can create efficient, sustainable, and safe transportation infrastructure using steel.

- Q: How are steel structures designed to be resistant to corrosion in industrial settings?

- Steel structures in industrial settings are designed to be resistant to corrosion through several methods. One common approach is to apply protective coatings, such as paint or specialized anti-corrosion coatings, that act as a barrier between the steel and the environment. Additionally, galvanization, which involves coating the steel with a layer of zinc, can provide enhanced corrosion resistance. Regular maintenance, including inspections and repairs of any damaged coatings, is also crucial to ensuring long-term corrosion resistance.

- Q: How do steel structures perform in earthquakes?

- Steel structures have proven to be highly effective in withstanding earthquakes. Due to their inherent strength and flexibility, steel is an ideal material for constructing earthquake-resistant buildings. When subjected to seismic forces, steel structures have the ability to absorb and dissipate energy, reducing the impact on the overall structure. One key advantage of steel structures is their ductility, which refers to their ability to deform without fracturing. During an earthquake, the steel members can bend and sway, absorbing the seismic energy and preventing the structure from collapsing. This ductile behavior allows steel buildings to undergo large deformations and redistribute the forces throughout the structure, thus minimizing damage. Additionally, steel structures are known for their high strength-to-weight ratio, making them lightweight yet incredibly strong. This characteristic allows for the construction of tall and slender buildings, which are more resistant to seismic forces. The lighter weight of steel also results in less inertia and lower forces generated during an earthquake, further enhancing the structure's performance. Moreover, steel structures can be designed to incorporate various earthquake-resistant features. These include the use of specialized connections between steel members, such as moment-resisting connections and base isolators, which enhance the structure's ability to withstand seismic forces. By employing these techniques, the energy from an earthquake is effectively absorbed and dissipated, reducing the risk of structural failure. Overall, steel structures have a proven track record of performance in earthquakes. Their ductility, strength, and ability to dissipate energy make them highly resilient to seismic forces. By incorporating appropriate design considerations and seismic-resistant features, steel buildings can provide a safe and secure environment even in areas prone to earthquakes.

- Q: How are steel structures used in the construction of agricultural buildings?

- Steel structures are widely used in the construction of agricultural buildings due to the many benefits they offer. Firstly, steel is an incredibly durable and strong material, making it perfect for supporting the large spans and heavy loads typically found in agricultural buildings. This means that wide open spaces can be constructed without the need for excessive interior columns or supports, allowing for maximum usable space for housing livestock, storing equipment, or other agricultural activities. Moreover, steel structures are highly resistant to fire, pests, and harsh weather conditions, creating a safe and secure environment for agricultural operations. This is especially important in areas prone to extreme weather events such as hurricanes or tornadoes, as steel structures can withstand high winds and minimize damage. Furthermore, steel structures provide great flexibility in design and can be easily customized to meet specific agricultural requirements. They can accommodate various building heights, roof pitches, and configurations, enabling efficient use of space and optimal functionality. Additionally, steel buildings can be erected relatively quickly, reducing construction time and costs. The longevity of steel structures is another advantage in agricultural settings. Steel is resistant to rot, corrosion, and decay, ensuring that the building will last for many years with minimal maintenance. This makes it a cost-effective choice for agricultural buildings, as it eliminates the need for frequent repairs or replacement. In conclusion, steel structures are essential in the construction of agricultural buildings due to their durability, strength, and flexibility. They provide a secure environment, maximize usable space, and ensure longevity, making them the ideal choice for farmers and agricultural businesses.

- Q: How do steel structures contribute to the overall occupant comfort of a building?

- There are several ways in which steel structures enhance the overall comfort of a building. To begin with, steel's strength and durability allow for the construction of large, open spaces without the need for excessive columns or supports. This creates more flexible and open floor plans, making the building feel more spacious and free. The absence of obstructions also improves natural light distribution and ventilation, making the building more comfortable for those inside. Additionally, steel structures can withstand extreme weather conditions like high winds or earthquakes, ensuring a safer environment for occupants. This resilience not only reduces the risk of structural damage but also instills a sense of security and peace of mind. Moreover, steel has excellent thermal conductivity, which means it can efficiently transfer heat or cold. This enables the building to maintain a comfortable temperature throughout the year. Steel structures can also be designed with insulation materials to enhance energy efficiency and reduce heating or cooling costs. This effective temperature control significantly contributes to occupant comfort by providing a pleasant indoor environment. Furthermore, steel structures can easily accommodate modern technological advancements such as smart building systems and automation. These systems can control lighting, temperature, and ventilation, optimizing comfort levels for occupants. The integration of such technologies enhances the overall occupant experience and convenience. Lastly, steel structures offer the advantage of being versatile and adaptable. They can be easily modified or expanded to meet changing needs or accommodate future growth. This flexibility ensures that the building can continuously be optimized for occupant comfort, whether through layout modifications, the addition of amenities, or the incorporation of sustainable features. In conclusion, steel structures contribute to the overall comfort of a building by providing strength, durability, safety, thermal efficiency, adaptability, and the potential for integrating advanced technologies. These factors work together to create a more comfortable and enjoyable environment for the building's occupants.

- Q: What are the advantages of using steel in the construction of shopping centers?

- There are several advantages of using steel in the construction of shopping centers. Firstly, steel is a highly durable material that can withstand heavy loads and extreme weather conditions, ensuring the longevity and structural integrity of the shopping center. Secondly, steel is a flexible material that allows for innovative and creative architectural designs, enabling developers to create visually appealing shopping centers. Additionally, steel is a cost-effective option as it can be prefabricated, reducing construction time and costs. Moreover, steel is a sustainable choice as it is recyclable, reducing the environmental impact of construction. Lastly, steel offers excellent fire resistance, ensuring the safety of occupants in case of a fire.

- Q: How are steel structures used in the construction of hotels and resorts?

- Steel structures are widely used in the construction of hotels and resorts due to their numerous benefits. Firstly, steel is a strong and durable material, making it ideal for supporting large and complex structures like hotels and resorts. The use of steel ensures that these buildings can withstand extreme weather conditions, earthquakes, and other natural disasters, providing a safe and secure environment for guests. Additionally, steel structures offer flexibility in design, allowing architects and engineers to create unique and visually appealing buildings. The versatility of steel allows for open floor plans, large spans, and the integration of various architectural features, such as glass facades or soaring atriums. This flexibility also allows for easy expansion or modification of the buildings in the future, accommodating the changing needs of the hotel or resort. Furthermore, steel structures enable faster construction times compared to traditional building materials. The components of a steel structure can be pre-fabricated off-site, reducing construction time on-site. This not only leads to cost savings but also allows hotels and resorts to be operational sooner, generating revenue at an earlier stage. Moreover, steel is an environmentally friendly material. It is highly recyclable, meaning that steel components can be reused or repurposed at the end of a building's life cycle. The use of steel in construction also reduces the need for timber, which helps to preserve forests and ecosystems. In conclusion, steel structures are extensively used in the construction of hotels and resorts due to their strength, durability, flexibility in design, faster construction times, and environmental benefits. These structures provide a solid foundation for creating aesthetically pleasing, safe, and sustainable buildings that meet the ever-evolving demands of the hospitality industry.

Send your message to us

C Channel Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords