Square Concrete Column Formwork AL65

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

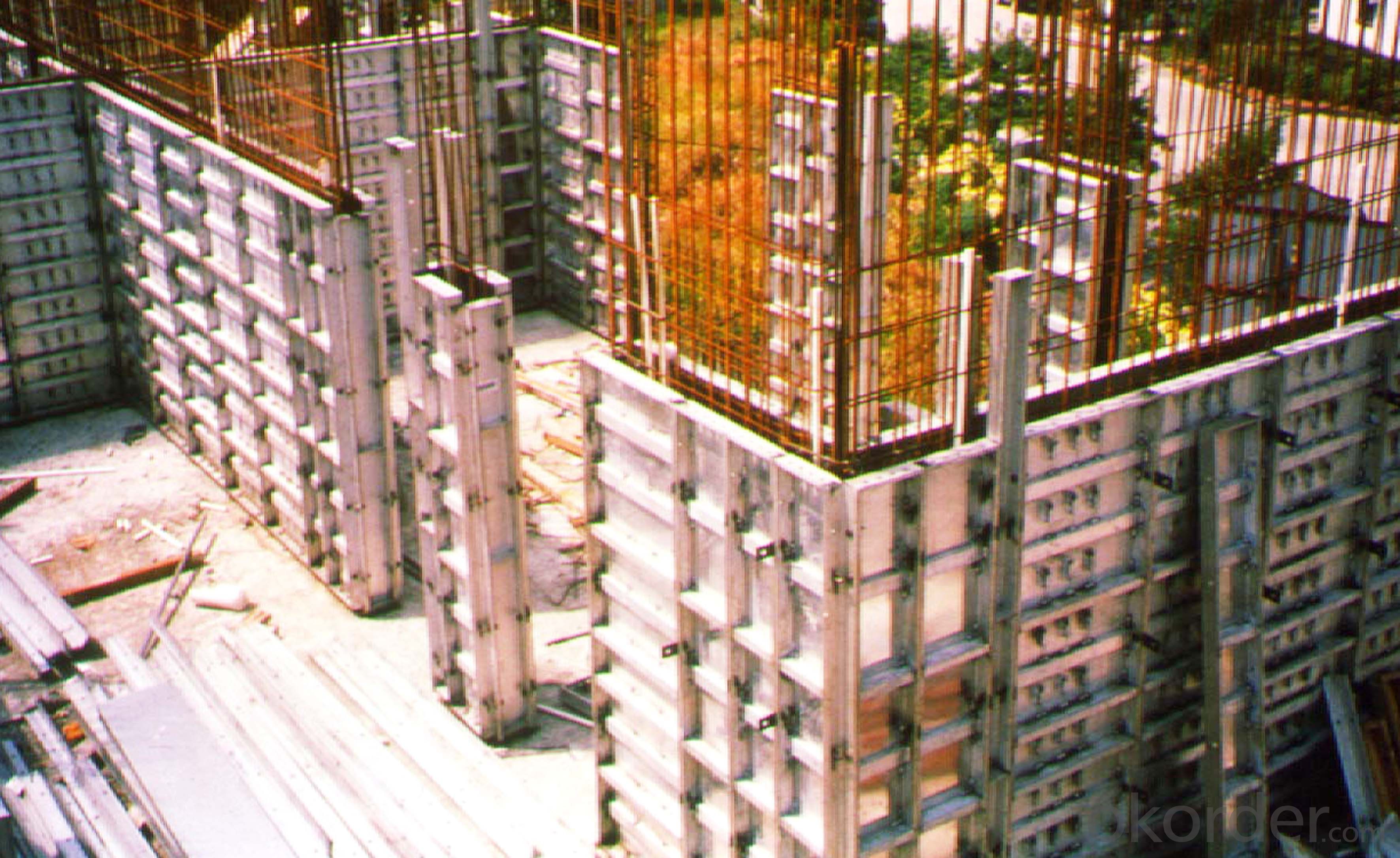

Custom SF63 Rectangle / Square

Column / Wall Construction

Adjustable Aluminum Formwork For Rectangle / Square Concrete Column

Description:

The whole system is made from aluminum materials. As the picture shown, every formwork unit is formed by CNBM production line. There are three special customized section bars form our standardization manufacture, and every formwork unit is welded by Robot.

AL 65 is a complete system with a full set of accessories, and can be set up flexibly according to project.

Competitive Advantage:

1. Lighter weight but high bearing capacity.

The allowable pressure from fresh concrete is 60KN/m2 with the thickness of 65mm.

2. Manual transportation can be achieved, greatly reduces the aggregate cost.

3. Perfect design, excellent produce and well welding make sure the flatness of concrete surface.

4. It is with the advantages of standard design, excellent applicability and interchangeable.

5. Simple, safe and fast.

6. No rust corrosion, easy maintenance, and high turnover rate.

Applications:

- Q: Can steel frame formwork be used for tunnel construction?

- Yes, steel frame formwork can be used for tunnel construction. Steel frame formwork is a versatile and durable system that is commonly used in various types of construction projects, including tunnel construction. It provides a strong and stable framework for pouring concrete, ensuring the walls and ceilings of the tunnels are formed accurately and with high precision. Steel frame formwork can be easily assembled and disassembled, allowing for efficient and cost-effective construction of tunnels. Additionally, steel frame formwork is resistant to environmental conditions, such as moisture and temperature variations, making it suitable for use in underground environments.

- Q: Are there any environmental concerns associated with steel frame formwork?

- Yes, there are a few environmental concerns associated with steel frame formwork. Firstly, the production of steel involves a significant amount of energy and emits greenhouse gases, contributing to climate change. The extraction and processing of raw materials for steel production also have negative environmental impacts, such as deforestation and habitat destruction. Additionally, steel frame formwork is often single-use, meaning it is used for a specific construction project and then discarded. This leads to a high amount of waste generation and contributes to landfill pollution. In contrast, reusable formwork systems made from sustainable materials like bamboo or recycled plastic can help reduce waste and minimize environmental impacts. Moreover, the transportation of steel formwork to construction sites requires fuel consumption and transportation emissions. This can further contribute to air pollution and carbon emissions. However, it is important to note that steel formwork has its advantages as well. It is durable, strong, and can be easily assembled and disassembled, making it popular in the construction industry. Additionally, steel can be recycled, which helps reduce the environmental impact of its disposal. To mitigate the environmental concerns associated with steel frame formwork, it is crucial to focus on improving the overall sustainability of construction practices. This can include using more eco-friendly alternatives, implementing efficient waste management strategies, promoting recycling, and adopting sustainable transportation methods. Additionally, incorporating renewable energy sources into steel production can help reduce its carbon footprint.

- Q: How does steel frame formwork contribute to the overall aesthetics of a concrete structure?

- Steel frame formwork contributes to the overall aesthetics of a concrete structure in several ways. Firstly, steel frame formwork allows for greater precision and accuracy in the placement of concrete, resulting in a smoother and more uniform finish. This is especially important in projects where the exposed concrete surface is intended to be a prominent design feature. Additionally, steel frame formwork provides flexibility in terms of shaping and molding the concrete. The steel frames can be easily adjusted and customized to create different shapes, curves, and patterns, allowing for more creative design possibilities. This enables architects and designers to create unique and visually appealing concrete structures that stand out from traditional construction techniques. Moreover, steel frame formwork helps in achieving a consistent and level surface finish across the entire structure. The rigid and sturdy nature of steel frames ensures that the formwork remains stable and does not deform during the concrete pouring process. This eliminates the risk of uneven surfaces or imperfections, resulting in a visually pleasing and professional appearance. Furthermore, steel frame formwork also contributes to the durability and longevity of the concrete structure. The use of steel frames provides strong support and reinforcement to the concrete, making it more resistant to external forces and potential damage. This ensures that the structure maintains its aesthetic appeal over time, as the concrete surface remains intact and free from cracks or deterioration. Overall, steel frame formwork plays a vital role in enhancing the overall aesthetics of a concrete structure. It allows for precise and accurate placement of concrete, provides flexibility in design, ensures a consistent and level finish, and contributes to the durability and longevity of the structure. By combining functionality and aesthetics, steel frame formwork helps create visually stunning and architecturally impressive concrete structures.

- Q: What is the lifespan of a steel frame formwork system?

- The lifespan of a steel frame formwork system can vary depending on factors such as maintenance, usage, and environmental conditions. However, with proper care and regular maintenance, a steel frame formwork system can last for several decades.

- Q: What are the safety measures that need to be taken while using steel frame formwork?

- When using steel frame formwork, there are several important safety measures that need to be taken to ensure the well-being of workers and the overall success of the construction project. These safety measures include: 1. Proper training and supervision: Workers should receive adequate training on the correct usage of steel frame formwork, including how to assemble, dismantle, and handle the equipment safely. They should also be supervised by experienced personnel to prevent any potential accidents. 2. Inspection and maintenance: Regular inspection of the steel frame formwork should be conducted to identify any defects, damages, or wear and tear. Any faulty or damaged components should be immediately replaced or repaired. Maintenance should also be carried out to keep the equipment in optimal condition. 3. Personal protective equipment (PPE): Workers should be equipped with appropriate PPE, such as safety helmets, safety goggles, gloves, and steel-toe boots, to protect themselves from potential hazards, such as falling objects or injuries during assembly and dismantling. 4. Secure footing and fall protection: Workers should have a secure footing when working on steel frame formwork structures. Proper scaffolding or platforms should be provided, and guardrails should be installed to prevent falls from heights. Additionally, safety harnesses and lanyards should be used when working at elevated levels. 5. Proper lifting techniques: Workers should be trained on proper lifting techniques to prevent strains or other musculoskeletal injuries when handling heavy components of the steel frame formwork. Mechanical aids, such as cranes or hoists, should be used whenever possible to minimize manual lifting. 6. Adequate lighting and ventilation: The work area should be well-lit to ensure good visibility, and proper ventilation should be provided to prevent the accumulation of harmful fumes or gases. 7. Communication and coordination: Effective communication and coordination between workers and supervisors are essential to ensure smooth operations and avoid accidents. Clear instructions, signals, and warning signs should be used to alert workers of any potential hazards or changes in the work environment. By following these safety measures, the risk of accidents and injuries can be greatly minimized when using steel frame formwork, creating a safer working environment for all involved.

- Q: How does steel frame formwork affect the overall durability of a concrete structure?

- Steel frame formwork can significantly enhance the overall durability of a concrete structure. The use of steel as a formwork material provides numerous advantages that contribute to the long-lasting nature of the concrete construction. Firstly, steel frame formwork offers exceptional strength and rigidity, allowing it to withstand high pressure and heavy loads during the pouring and curing process of the concrete. This strength eliminates the risk of deformation or collapse during the construction phase, ensuring the structural integrity of the concrete structure. Moreover, steel is highly resistant to corrosion, which is a crucial factor in enhancing the durability of the concrete structure. Unlike other formwork materials such as wood or plywood, steel does not rot, warp, or deteriorate over time due to moisture or exposure to the elements. This resistance to corrosion ensures the long-term stability and strength of the concrete structure, even in harsh environmental conditions. Additionally, steel frame formwork offers superior dimensional stability, ensuring that the concrete elements maintain their intended shape and dimensions over time. This prevents any potential cracks or deformations from occurring in the concrete structure, thereby enhancing its overall durability. Furthermore, steel formwork allows for precise and accurate construction, resulting in minimal variations and imperfections in the finished concrete structure. This precision ensures that the structure is built to the desired specifications, reducing the risk of future issues or structural failures. Lastly, steel frame formwork is reusable, making it a sustainable and cost-effective choice for concrete construction. The ability to reuse the formwork reduces material waste and construction costs, while still maintaining the durability and quality of the concrete structure. In conclusion, steel frame formwork plays a pivotal role in enhancing the overall durability of a concrete structure. Its strength, resistance to corrosion, dimensional stability, precision, and reusability all contribute to a long-lasting and robust construction that can withstand the test of time.

- Q: What are the different finishes that can be achieved with steel frame formwork?

- Different finishes can be achieved with steel frame formwork in construction projects, depending on the type of formwork used and the techniques employed during the pouring and curing of the concrete. 1. A smooth finish can be created on the concrete surface by using high-quality formwork materials, ensuring a tight fit between the formwork panels, and using appropriate release agents to prevent the concrete from sticking. Architects often prefer a smooth finish for its aesthetic appeal and the ease of cleaning or painting the concrete surface. 2. Various textures can be achieved on the concrete surface using steel frame formwork. This can be done by attaching specialized form liners or molds to the formwork panels. These liners or molds can create patterns, imitate natural materials like wood or stone, or add decorative elements to the concrete surface. Textured finishes are commonly used in building facades, interior walls, or for aesthetic purposes. 3. An exposed aggregate finish is possible with steel frame formwork. This finish is achieved by using form liners or molds that create voids or recesses in the concrete. After the concrete cures, the formwork is removed, and the surface is treated to expose the aggregates in the concrete mix. Exposed aggregate finishes are commonly seen in sidewalks, driveways, or decorative concrete elements. 4. Steel frame formwork can be combined with stamping techniques to create a stamped finish on the concrete surface. Specialized stamps or patterns are pressed into the concrete while it is still in a plastic state. These stamps can create various textures, imitate natural materials, or add decorative elements to the concrete surface. Stamped finishes are frequently used for patios, walkways, or outdoor areas. In conclusion, steel frame formwork provides a range of finishes for concrete construction, including smooth, textured, exposed aggregate, and stamped finishes. Each finish offers unique aesthetic and functional characteristics, and the choice depends on the desired outcome, project requirements, and architectural design considerations.

- Q: What are the different types of wall formwork systems that can be used with steel frame formwork?

- There are several different types of wall formwork systems that can be used with steel frame formwork. Some of the common types include: 1. Panel formwork: This is the most commonly used type of wall formwork system. It consists of large prefabricated panels made of plywood or steel framed with plywood. These panels are connected together to form a solid wall formwork. 2. Climbing formwork: This type of formwork is used for constructing tall walls or high-rise buildings. It consists of a self-climbing system that allows the formwork to be lifted vertically as the construction progresses. This eliminates the need for external scaffolding and provides a safer and more efficient construction process. 3. Slip formwork: Slip formwork is used for constructing vertical structures with a smooth finish, such as elevator shafts or chimney stacks. It involves a continuous pouring of concrete into a moving formwork system. As the concrete sets, the formwork is slowly raised, creating a seamless concrete structure. 4. Tunnel formwork: This type of formwork is used for constructing walls in tunnels or underground structures. It consists of large steel forms that are assembled and connected together to create a continuous wall formwork system. The forms are then filled with concrete to create the tunnel walls. 5. Jump formwork: Jump formwork is used for constructing vertical structures with a repetitive pattern, such as columns or piers. It involves a system of adjustable vertical forms that are lifted and repositioned as the construction progresses. This allows for fast and efficient construction of multiple vertical elements. These are just a few examples of the different types of wall formwork systems that can be used with steel frame formwork. The choice of system will depend on the specific requirements of the project, including the type of structure being built, the height of the walls, and the desired finish.

- Q: What are the different types of supports used in steel frame formwork systems?

- There are several types of supports used in steel frame formwork systems, including adjustable props, scaffolding, and horizontal and vertical beams. These supports help to provide stability and ensure proper alignment and positioning of the formwork during construction.

- Q: How does steel frame formwork contribute to the overall structural integrity of a building?

- Steel frame formwork contributes to the overall structural integrity of a building in several ways. Firstly, steel frame formwork provides a robust and sturdy support system for the concrete during the pouring and curing process. The rigid steel frame ensures that the formwork maintains its shape and can withstand the pressure exerted by the wet concrete. This prevents any distortion or deformation of the formwork, ensuring that the concrete is poured accurately and evenly, resulting in a consistent and strong structure. Furthermore, steel frame formwork allows for precise and accurate alignment of the concrete elements. The steel frames can be easily adjusted and leveled, ensuring that the concrete is poured in the desired position and alignment. This is crucial for maintaining the structural integrity of the building, as any misalignment or unevenness can lead to weak spots or compromised load-bearing capacity. Additionally, steel frame formwork provides excellent reusability and durability. Unlike traditional timber formwork, steel frames can be used repeatedly without deterioration or loss of strength. This not only saves costs and reduces waste but also ensures that the formwork remains structurally sound throughout multiple construction cycles. The durability of steel frame formwork contributes to the long-term stability and integrity of the building, as it can withstand various loads and environmental conditions without compromising its structural performance. Moreover, steel frame formwork allows for efficient construction processes. The modular design of the steel frames enables quick assembly and disassembly, reducing construction time and labor costs. This efficiency in construction contributes to the overall structural integrity of the building, as it minimizes the chances of errors or delays that could potentially compromise the structural strength. In summary, steel frame formwork plays a vital role in enhancing the overall structural integrity of a building. Its robustness, precise alignment, reusability, durability, and efficiency contribute to the accurate and consistent pouring of concrete, ensuring a strong and stable structure that can withstand various loads and environmental conditions.

Send your message to us

Square Concrete Column Formwork AL65

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords