Steel Billets Q235 Q235 Q275 Q345 for Fire Door Billet Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

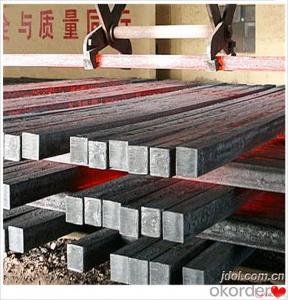

Steel Billets Q235 Q235 Q275 Q345 for Fire Door Billet Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

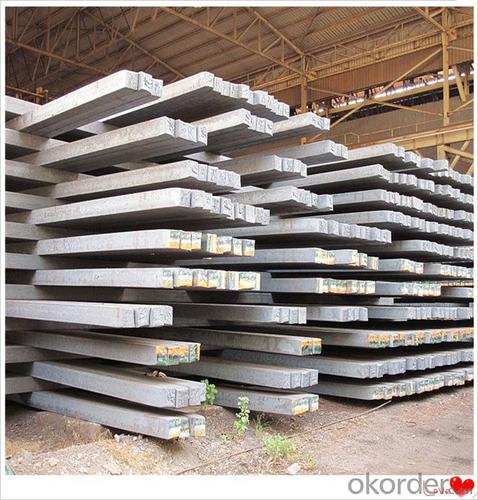

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

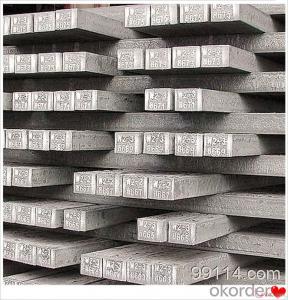

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the potential applications of steel billets in the oil and gas industry?

- The oil and gas industry can utilize steel billets in a wide range of ways. These include, but are not limited to, the following: 1. Manufacturing pipes: Steel billets can be used to create pipes that are crucial for transporting oil and gas. The strength and durability of steel make it an excellent choice for constructing pipes that can withstand the harsh conditions of drilling, extraction, and transportation. 2. Creating drill collars: Steel billets can be machined into drill collars, which are heavy steel tubes used in drilling. Drill collars provide weight to the drill string, increasing the force applied to the drill bit. The strength and toughness of steel billets make them suitable for this application, as they can withstand the high torque and pressure exerted during drilling. 3. Making downhole tools: Steel billets can also be used to manufacture a variety of downhole tools used in oil and gas exploration, including stabilizers, reamers, and subs. These tools are crucial for maintaining wellbore stability, clearing obstructions, and enhancing drilling efficiency. The ability of steel billets to withstand high temperatures, pressures, and abrasive environments makes them suitable for these tools. 4. Constructing offshore structures: Steel billets can be used in the construction of offshore platforms, jackets, and other structural components. These structures must withstand extreme weather conditions, corrosive environments, and heavy loads. Steel billets, with their high strength, corrosion resistance, and weldability, are an ideal choice for such applications. 5. Machining equipment and machinery components: Steel billets can be machined into various components and parts for oil and gas equipment and machinery. This includes valves, fittings, flanges, connectors, and other critical components used in drilling rigs, pipelines, refineries, and processing facilities. The versatility and reliability of steel make it a preferred material for such applications. In summary, steel billets have a wide range of potential applications in the oil and gas industry. Their high strength, durability, corrosion resistance, and versatility make them essential in pipe manufacturing, the creation of drill collars and downhole tools, the construction of offshore structures, and the machining of equipment components. Steel billets play a crucial role in ensuring the efficiency, safety, and reliability of oil and gas operations.

- Q: What are the main safety considerations when handling steel billets?

- The main safety considerations when handling steel billets include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Proper lifting techniques should be used to prevent strains and back injuries when moving heavy billets. Additionally, ensuring a well-organized and clutter-free work area, as well as proper storage and stacking of the billets, can help prevent accidents and injuries.

- Q: What is the drop per minute of the billet temperature at 850?

- Cold rolling is not considered. The initial rolling temperature (surface) of the billet is generally 1000-1150 degrees. Generally, the temperature decreases gradually during the rolling process (a small section of high speed wire has a temperature rising process), usually above 750 degrees

- Q: Are steel billets used in the production of household appliances?

- Indeed, steel billets find application in the manufacturing of household appliances. Serving as intermediate steel products, steel billets are employed as primary materials across various industries, encompassing the production of household appliances. Following the process of heating, these billets are either rolled or forged into diverse forms and dimensions, thereby fabricating essential components such as sheets, plates, rods, and bars, pivotal in the creation of appliances. Steel, due to its robustness, longevity, and ability to resist corrosion, becomes a favored choice in the realm of household appliances. Consequently, steel is extensively utilized in the production of a wide array of household appliances, including refrigerators, washing machines, dishwashers, ovens, and several others.

- Q: What are the different types of steel billet extrusion processes?

- There are several different types of steel billet extrusion processes used in the manufacturing industry. These processes involve shaping a solid steel billet into a desired profile or shape by applying high pressure. 1. Direct Extrusion: This is the most common type of steel billet extrusion process. In this method, the billet is placed inside a container called a "container" or "container die." The container has a small opening called a "die" through which the billet is forced using a ram or a piston. The steel billet is pushed through the die, and the resulting shape is formed. 2. Indirect Extrusion: In this process, the container die is stationary, and the billet is pushed through the die using a punch or a ram. The billet is placed inside a hollow chamber called a "container" or "container die" with a smaller diameter opening at one end. The punch is then used to apply pressure on the billet, forcing it to flow through the die and take the shape of the desired profile. 3. Impact Extrusion: This process is similar to direct extrusion, but it involves using a punch with a specially designed shape. The punch strikes the billet with a high impact force, causing it to flow and take the shape of the die. Impact extrusion is commonly used for producing small, intricate shapes with thin walls. 4. Hydrostatic Extrusion: In this process, the billet is placed inside a sealed chamber filled with a pressurized fluid, usually oil or water. The fluid pressure is applied to the billet, forcing it to flow through the die and take the desired shape. Hydrostatic extrusion is often used for producing complex shapes with high precision. 5. Cold Extrusion: This process involves extruding the steel billet at room temperature, without the need for heating. Cold extrusion is commonly used for producing small, intricate parts with high dimensional accuracy. It is a cost-effective method that allows for the production of parts with excellent surface finish. Each of these steel billet extrusion processes has its own advantages and limitations, and the choice of process depends on factors such as the desired shape, size, material properties, and production requirements.

- Q: How can the quality of steel billets be improved?

- There are several methods and techniques that can be employed to improve the quality of steel billets. Below are some approaches that can assist in enhancing the quality of steel billets: 1. Raw Material Selection: The quality of steel billets heavily relies on the selection of raw materials. Opting for high-quality raw materials, such as top-grade iron ore and scrap metal, can considerably enhance the quality of billets. 2. Melting and Refining: The melting and refining process play a pivotal role in enhancing steel billet quality. The utilization of advanced melting practices, like electric arc furnaces (EAF) or induction furnaces, can aid in achieving a more uniform and controlled melting process, reducing impurities, and achieving the desired chemical composition. 3. Deoxidation and Degassing: It is essential to employ appropriate deoxidation and degassing techniques to eliminate impurities and gases from the molten metal. This can be accomplished by incorporating suitable deoxidizers and utilizing vacuum degassing processes that efficiently remove unwanted gases, thus enhancing the quality of steel billets. 4. Continuous Casting Process: The implementation of a modern continuous casting process can significantly improve the quality of steel billets. Continuous casting ensures a more consistent structure, reduces segregation, and minimizes the formation of defects commonly associated with traditional ingot casting methods. 5. Heat Treatment: The application of suitable heat treatment processes, such as annealing, quenching, and tempering, can further enhance the mechanical properties and overall quality of steel billets. Heat treatment helps refine the microstructure, improving the strength, hardness, and other desired characteristics of the steel. 6. Quality Control: A robust quality control system is crucial to ensure the production of high-quality steel billets. Regular monitoring and testing should be conducted throughout the production process to promptly identify and rectify any deviations or quality issues. 7. Skilled Workforce: Employing a skilled and knowledgeable workforce is vital for improving the quality of steel billets. Well-trained technicians and operators can effectively implement various quality improvement techniques and address any production challenges that may arise. By incorporating these methods and techniques, steel manufacturers can enhance the quality of steel billets, resulting in improved mechanical properties, superior surface finish, and increased customer satisfaction.

- Q: What are the different surface treatments applied to alloy steel billets?

- Some of the different surface treatments applied to alloy steel billets include hot rolling, cold drawing, peeling, grinding, and polishing. These treatments are used to improve the surface finish, dimensional accuracy, and overall quality of the billets.

- Q: What is the role of steel billets in the construction of airports and terminals?

- Steel billets play a crucial role in the construction of airports and terminals due to their various advantageous properties. They are essentially semi-finished metal products that are used as a raw material in the manufacturing of different steel products. In the context of airports and terminals, steel billets are primarily utilized for the production of structural steel components such as beams, columns, and trusses. One of the key reasons why steel billets are preferred in the construction industry is their strength and durability. Steel is renowned for its high tensile strength, which allows it to withstand heavy loads and structural stresses. This makes it an ideal material for constructing large and complex structures like airports and terminals, where safety and reliability are paramount. Additionally, steel billets can be easily fabricated into various shapes and sizes, making them versatile for constructing different components required in airports and terminals. These billets are often hot rolled or forged into the desired shapes, ensuring that the resulting steel products have the necessary strength and structural integrity. Another crucial advantage of steel billets in the construction of airports and terminals is their resistance to adverse environmental conditions. Airports and terminals are exposed to harsh weather conditions, including extreme temperatures, moisture, and corrosion. Steel, especially when properly coated or treated, is highly resistant to these factors, ensuring the longevity and structural stability of the constructed facilities. Moreover, steel billets are relatively cost-effective compared to other construction materials, especially when considering their durability and low maintenance requirements. The long lifespan of steel structures reduces the need for frequent repairs or replacements, resulting in cost savings over time. In summary, steel billets play a vital role in the construction of airports and terminals by providing the necessary strength, durability, and versatility required for large-scale structures. Their ability to withstand heavy loads, resistance to environmental factors, and cost-effectiveness make them an ideal choice for such high-demand facilities.

- Q: What are the potential applications of steel billets in the transportation sector?

- Due to their strength, durability, and versatility, steel billets offer a wide range of potential applications in the transportation sector. One primary use is in the manufacturing of various vehicle components, such as engine parts, suspension systems, axles, and other critical parts that require high strength and resistance to wear and tear. Moreover, steel billets can be utilized in the construction of railway tracks, bridges, and tunnels. With its high tensile strength, steel is an ideal material for infrastructure projects as it can withstand heavy loads and provide long-lasting performance. It is also suitable for manufacturing shipbuilding components like hulls, propellers, and deck structures, offering excellent corrosion resistance and structural integrity in marine environments. Additionally, steel billets find use in the production of transportation equipment like trailers, trucks, and buses. Its strength and durability make it an ideal material for constructing the chassis and frames of these vehicles, ensuring their safety and longevity. In the automotive industry, steel billets are commonly used for producing car bodies and frames. The lightweight yet robust characteristics of steel make it a preferred choice for enhancing fuel efficiency and crashworthiness in vehicles. Furthermore, manufacturers can shape steel billets into intricate designs, allowing them to create aesthetically pleasing and aerodynamic vehicle structures. In conclusion, the strength, durability, and versatility of steel billets make them essential in the transportation sector. They are used in various applications, ranging from vehicle components to infrastructure projects. By ensuring safety, reliability, and longevity, steel billets play a vital role in the industry.

- Q: What are the different types of steel billets?

- There are several different types of steel billets, each with its own unique characteristics and applications. Some of the most common types include: 1. Carbon Steel Billets: These are the most widely used type of steel billets and are made from iron and carbon. Carbon steel billets are known for their high strength and durability, making them suitable for a wide range of applications, including construction, automotive, and machinery manufacturing. 2. Alloy Steel Billets: These billets are made by adding various alloying elements to carbon steel, such as chromium, nickel, or manganese. Alloy steel billets offer enhanced properties such as increased strength, hardness, and corrosion resistance. They are often used in industries that require high-performance materials, such as aerospace, oil and gas, and power generation. 3. Stainless Steel Billets: Stainless steel billets are made with a high content of chromium, which provides excellent resistance to corrosion and oxidation. They are commonly used in applications where hygiene, durability, and aesthetic appearance are crucial, such as food processing, medical equipment, and architectural structures. 4. Tool Steel Billets: Tool steel billets are specially designed to have high hardness, wear resistance, and heat resistance. They are commonly used to make cutting tools, molds, and dies for various industries, including automotive, manufacturing, and construction. 5. Electrical Steel Billets: Electrical steel billets are made from low carbon steel with specific magnetic properties. They are used in the manufacturing of electrical equipment, such as transformers, motors, and generators, where low energy loss and high magnetic permeability are vital. 6. High-speed Steel Billets: High-speed steel billets are alloyed with elements like tungsten, molybdenum, and cobalt, which enable them to retain their hardness and strength at high temperatures. They are widely used to make cutting tools that need to withstand high-speed cutting operations, such as drills, milling cutters, and taps. These are just a few examples of the different types of steel billets available. The choice of steel billet depends on the specific requirements of the application, such as strength, durability, corrosion resistance, or special properties needed for particular industries.

Send your message to us

Steel Billets Q235 Q235 Q275 Q345 for Fire Door Billet Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords