Largest Steel Billet Factory Q235 Q275 Q345 for Stoves Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Largest Steel Billet Factory Q235 Q275 Q345 for Stoves Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

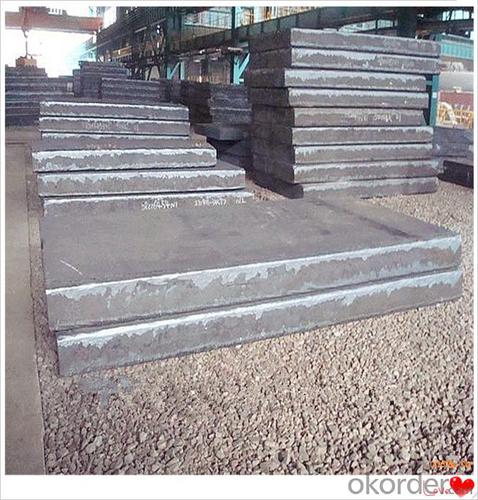

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

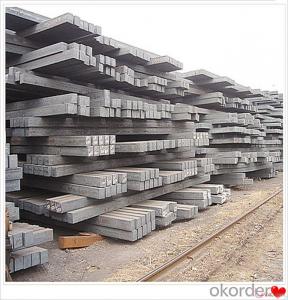

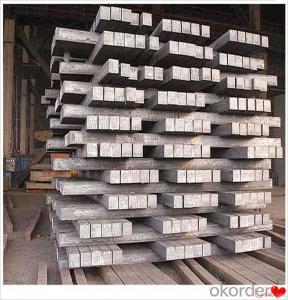

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

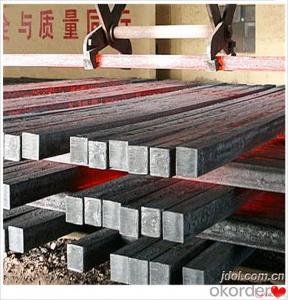

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

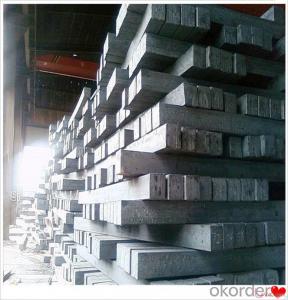

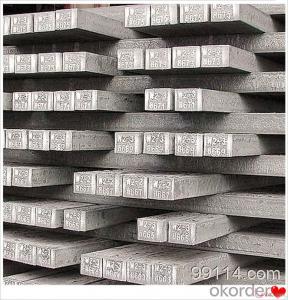

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What is the impact of impurities on the quality of steel billets?

- The quality of steel billets is greatly influenced by impurities. Steel billets, which serve as raw materials for various steel products, can be negatively affected by the presence of impurities. To begin with, the mechanical properties of steel billets can be weakened by impurities. For example, sulfur can cause sulfide inclusions, which reduce the strength and toughness of the steel. Similarly, phosphorus can lead to phosphide inclusions that negatively impact the ductility and impact resistance of the billets. These impurities can also promote the formation of cracks and other defects, further compromising the quality of the steel. Additionally, the machinability of steel billets can be adversely affected by impurities. Higher levels of impurities can increase the hardness and decrease the machinability of the steel, making it more challenging to shape into the desired end products. Consequently, this can lead to increased processing time and cost, as well as reduced productivity. Furthermore, the surface finish of steel billets can be impacted by impurities. Oxide inclusions, which are commonly formed due to impurities, can cause surface defects and roughness. This can negatively affect the appearance and aesthetics of the final steel products, making them less desirable in the market. Moreover, impurities can influence the corrosion resistance of steel billets. Some impurities, like chromium and nickel, can improve the corrosion resistance of steel. However, other impurities such as sulfur and phosphorus can promote corrosion, decreasing the lifespan and reliability of the steel products made from these billets. In conclusion, impurities have a significant impact on the quality of steel billets, resulting in weakened mechanical properties, reduced machinability, compromised surface finish, and decreased corrosion resistance. Therefore, it is crucial for steel manufacturers to carefully control and minimize the presence of impurities during the production process to ensure the production of high-quality steel billets.

- Q: Are steel billets used in the renewable energy sector?

- Yes, steel billets are used in the renewable energy sector. They are commonly used in the manufacturing of wind turbine components, solar panel frames, and other renewable energy infrastructure.

- Q: What is the role of steel billets in the manufacturing of industrial boilers?

- The role of steel billets in the manufacturing process of industrial boilers is crucial. These billets act as the raw material from which the various components of the boiler are formed. Industrial boilers are complex structures that require durable materials of high quality to withstand the harsh operating conditions. Steel billets, typically made from carbon steel or alloy steel, possess excellent strength and corrosion resistance properties. They undergo a heating process before being shaped into different forms such as plates, tubes, or rods through rolling, extrusion, or forging. These formed components are then processed and assembled to create the boiler. During the manufacturing process, steel billets are used to fabricate important boiler components including the shell, tubes, and flues. The shell, made from steel plates, forms the main body of the boiler, while the tubes and flues allow for the passage of hot gases and water. Steel billets ensure the structural integrity of these components, enabling them to withstand high temperatures and pressures without deformation or failure. Additionally, steel billets are utilized in the creation of other auxiliary components of industrial boilers such as supports, brackets, and fittings. These components are vital for the proper functioning and installation of the boiler, ensuring stability, efficiency, and safety. In summary, steel billets are essential to the manufacturing of industrial boilers due to their ability to provide the necessary strength, durability, and versatility required to withstand demanding operating conditions. The utilization of high-quality steel billets guarantees that the boilers are reliable, long-lasting, and capable of meeting the rigorous performance standards expected in industrial applications.

- Q: What are the different methods of shaping steel billets?

- There are several methods of shaping steel billets, including hot rolling, cold rolling, forging, extrusion, and casting. Each method involves different techniques and processes to shape the steel billets into desired forms and dimensions.

- Q: What are the potential applications of steel billets in the automotive industry?

- Steel billets have a wide range of potential applications in the automotive industry. They can be used in the production of various components such as engine parts, chassis, suspension systems, and body panels. Steel billets offer excellent strength, durability, and high melting points, making them ideal for ensuring the safety and reliability of vehicles. Additionally, their versatility allows for customization and lightweight designs, contributing to improved fuel efficiency and overall performance.

- Q: How do steel billets contribute to the water treatment industry?

- Steel billets are an essential component in the water treatment industry as they play a significant role in the manufacturing of various equipment and structures used in water treatment processes. These billets are primarily used in the construction of pipelines, tanks, and other infrastructure required for water treatment plants. One of the most crucial applications of steel billets in the water treatment industry is the production of pipe fittings. These fittings are used to connect different sections of pipelines, allowing the seamless transportation of water and other fluids within the treatment facility. Steel billets are commonly used in the manufacturing of these fittings due to their high strength and durability, ensuring the longevity and reliability of the pipeline system. Moreover, steel billets are also utilized in the construction of tanks and vessels used for storing and treating water. These tanks are often subjected to harsh and corrosive conditions, and steel billets are preferred due to their corrosion resistance properties. Additionally, steel is a non-porous material, preventing the contamination of water within the tanks and ensuring the water remains clean and safe for consumption. Additionally, steel billets are used in the fabrication of screens and filters used in the water treatment process. These screens and filters are crucial in removing impurities, sediments, and other contaminants from the water. Steel billets provide the necessary strength and structural integrity to withstand the pressure and flow of water while effectively filtering out unwanted particles. Furthermore, steel billets are also utilized in the construction of various structures within water treatment plants, such as walkways, platforms, and supports. These structures are essential for providing safe access to equipment and facilitating maintenance and repair activities. Steel billets are favored for such applications due to their high load-bearing capacity and resistance to environmental factors like moisture and chemicals. In summary, steel billets are indispensable in the water treatment industry. Their strength, durability, corrosion resistance, and versatility make them the material of choice for the construction of pipelines, tanks, fittings, screens, and other structures necessary for efficient and effective water treatment processes.

- Q: How are steel billets used in the production of sheet metal?

- The production of sheet metal involves using steel billets in a process called rolling. Rolling entails passing steel billets through a series of rollers in order to decrease their thickness and create a flat sheet. To begin the process, the steel billets are heated to a specific temperature, which enhances their malleability. Once heated, the billets are fed into a rolling mill where they pass through a sequence of rollers that gradually reduce the thickness of the steel. As the billets are rolled, they undergo compression and elongation, resulting in a thinner and longer piece of steel. This procedure is repeated multiple times, with each pass further reducing the thickness of the steel sheet. After reaching the desired thickness, the sheet is cooled and cut into specific lengths. The end product is a flat sheet of sheet metal that can be further processed and utilized in various industries, including construction, automotive, and manufacturing. Steel billets play a vital role in the production of sheet metal as they serve as the raw material from which the sheets are formed. Their malleability and ability to withstand the rolling process make them an excellent choice for creating thin and long-lasting sheet metal.

- Q: How do steel billets contribute to the manufacturing of medical devices?

- Steel billets contribute to the manufacturing of medical devices in various ways. Firstly, steel billets serve as the raw material for the production of medical devices. These billets are used as a starting point in the manufacturing process, where they are heated and shaped into the desired form using techniques like forging, casting, or rolling. The use of steel billets in medical device manufacturing offers several advantages. Steel is known for its strength, durability, and corrosion resistance, making it an ideal material for the production of medical devices that need to withstand rigorous use and maintain their integrity over time. Additionally, steel offers excellent biocompatibility, meaning it is well-tolerated by the human body, reducing the risk of adverse reactions or complications when the medical devices are implanted or used in surgical procedures. Moreover, steel billets can be easily machined and formed into complex shapes, allowing manufacturers to create intricate medical devices such as orthopedic implants, surgical instruments, or prosthetic components. Steel's versatility and malleability enable the production of devices with precise dimensions and fine details, ensuring optimal functionality and performance. Furthermore, steel billets contribute to the manufacturing of medical devices by providing a cost-effective solution. Steel is widely available and relatively affordable compared to other materials used in the medical industry, making it an attractive choice for manufacturers. The ability to produce medical devices from steel billets at a reasonable cost contributes to the accessibility and affordability of healthcare worldwide. In conclusion, steel billets play a crucial role in the manufacturing of medical devices. They provide a strong, durable, and biocompatible material that can be easily shaped and machined into complex forms. Steel's properties contribute to the production of high-quality medical devices that are capable of withstanding demanding applications while ensuring patient safety and cost-effectiveness.

- Q: How are steel billets used in the manufacturing of machine parts?

- Steel billets are used in the manufacturing of machine parts as a starting material. They are heated, shaped, and further processed through various techniques such as forging, rolling, or machining to create specific components with desired dimensions and properties.

- Q: After processing to the color coating board, is there a fare increase of 1000?The price of galvanized coil is about +350 per ton of cold-rolled steel at present What about the cost of billet to cold rolling?What is the final cost of making the color coated sheet? How do you figure that?

- The cost of billet to cold rolling is about 1000Galvanized to color coated sheet costs vary greatly, generally around 300, a high of 500

Send your message to us

Largest Steel Billet Factory Q235 Q275 Q345 for Stoves Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords