120mm Steel Billets Q235 Q275 Q345 Professional Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

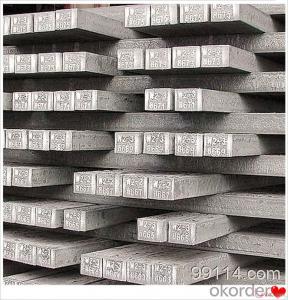

120mm Steel Billets Q235 Q275 Q345 Professional Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

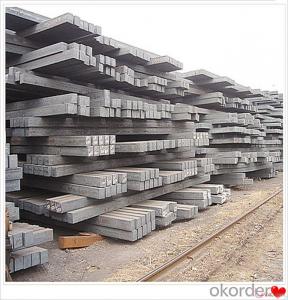

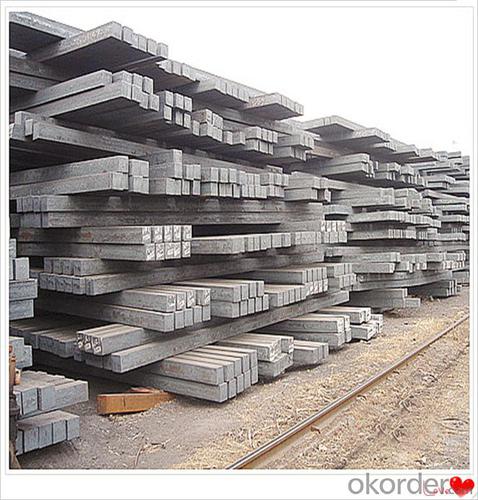

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the different types of forging processes used for shaping steel billets?

- There are several different types of forging processes that are commonly used for shaping steel billets. These processes include open die forging, closed die forging, and ring rolling. Open die forging is a process in which the steel billet is placed between two flat dies and compressed to shape it. This process is commonly used for larger and simpler shapes, as the steel is not completely enclosed by the dies, allowing for more flexibility in the final shape. Closed die forging, also known as impression die forging, involves the use of specially designed dies that contain cavities in the shape of the desired final product. The steel billet is placed between these dies and compressed, causing the metal to flow and take on the shape of the cavities. This process is commonly used for more complex shapes and allows for greater precision and control over the final product. Ring rolling is a forging process used specifically for shaping steel billets into rings. The billet is placed on a mandrel, and a series of rollers apply pressure to the billet, causing it to deform and take on the shape of a ring. This process is commonly used in the production of seamless rolled rings, which are widely used in industries such as aerospace, oil and gas, and power generation. Overall, these different types of forging processes offer various advantages and are chosen based on the complexity of the desired shape, the required precision, and the specific requirements of the end application.

- Q: How are steel billets used in the manufacturing of slabs?

- The manufacturing of slabs relies heavily on steel billets, which are vital raw materials. Slabs, being sizable and flat steel pieces, are widely used in various industries like construction, automotive, and manufacturing. To create slabs, the initial step involves obtaining steel billets. These billets are partially finished steel products that are usually acquired through continuous casting or hot-rolling ingots. They are solid blocks of steel, either rectangular or square-shaped, and their cross-sectional area varies depending on the desired size and thickness of the slabs. Once the steel billets are acquired, they undergo heating to a high temperature, making them more pliable and easier to shape. This heating process, known as hot rolling, entails passing the billets through a series of rolling mills, gradually reducing their thickness and increasing their length. Intense pressure is applied to the billets in the rolling mills, resulting in elongation and the attainment of the desired dimensions. Throughout the hot rolling process, the steel billets are often subjected to different manipulations, such as reheating and cooling, to ensure proper shaping and metallurgical properties. Additional processes like descaling (removal of the oxide layer) and surface treatment may also be performed on the billets to enhance their quality and finish. Upon completion of the hot rolling process, the steel billets are transformed into slabs. These slabs then undergo further processing to meet specific requirements. For example, they may undergo additional rolling or reheating to achieve the desired thickness, dimensions, and surface finish. Depending on the intended use, the slabs can be cut into smaller pieces or further processed into various steel products like plates, sheets, or coils. In conclusion, steel billets are of utmost importance in the manufacturing of slabs. They serve as the starting point for the production process, undergoing hot rolling and other treatments to shape them into the desired form, size, and quality. The resulting slabs are then used as a key input across multiple industries, contributing to the production of a wide range of steel products.

- Q: Are steel billets used in the manufacturing of tools?

- Steel billets are widely used in tool manufacturing. They are semi-finished steel products that are usually hot-rolled or forged into different shapes like bars, rods, and sheets. These billets act as the main raw material for making high-quality tools because they offer the required strength, durability, and machinability. Manufacturers can shape and machine the steel billets to create a wide range of tools such as wrenches, hammers, screwdrivers, drill bits, and cutting tools. The use of steel billets ensures that these tools have the necessary hardness, toughness, and resistance to wear and tear, making them dependable and long-lasting. Consequently, steel billets play a vital role in tool production, enhancing the overall efficiency and functionality of various industries.

- Q: Use medium frequency furnace (1 million 500 thousand volt ampere) to produce 1 ton cast steel blank, how much kilowatt hour is consumed?

- This depends on the intermediate frequency furnace voltage level and inverter efficiency, the general high voltage will save power, generally 550-700 range, details can refer to wcdlsb site medium frequency furnace data

- Q: What are the different testing methods used for steel billets?

- There are several testing methods used for steel billets to ensure their quality and suitability for various applications. These methods include: 1. Visual Inspection: This is the simplest and most common method used to assess the overall quality and surface condition of steel billets. Inspectors visually examine the billets for any visible defects such as cracks, surface irregularities, or foreign materials. 2. Dimensional Inspection: Steel billets must meet specific dimensional requirements. Dimensional inspection involves measuring the length, width, and height of the billets using calibrated tools to ensure they meet the specified tolerances. 3. Ultrasonic Testing: Ultrasonic testing is a non-destructive testing method that uses high-frequency sound waves to detect any internal defects in the billets. A transducer is used to send sound waves into the material, and any reflected waves are analyzed for indications of flaws or inconsistencies. 4. Magnetic Particle Inspection: This method is primarily used to detect surface and near-surface defects in steel billets. A magnetic field is applied to the billet, and a magnetic particle solution is then applied to the surface. Any defects or cracks will cause the particles to collect and create visible indications. 5. Eddy Current Testing: Eddy current testing involves passing an alternating current through a probe, which generates an electromagnetic field. When the probe is placed near the billet's surface, any changes in the electrical conductivity or magnetic permeability of the material will create eddy currents, indicating the presence of defects. 6. Chemical Analysis: Chemical analysis is performed to determine the composition of the steel billets, including the percentage of various elements such as carbon, manganese, silicon, and others. This analysis ensures that the billets meet the specified chemical composition required for their intended use. 7. Tensile Testing: Tensile testing measures the mechanical properties of steel billets, including their strength, ductility, and elasticity. A sample is taken from the billet and subjected to tension until it fractures. The force applied and the resulting elongation or deformation are measured to determine the billet's mechanical properties. By utilizing these testing methods, steel billets can be thoroughly assessed for any defects, dimensional discrepancies, and material properties, ensuring their compliance with industry standards and meeting the specific requirements for their intended applications.

- Q: What are the main factors that influence the strength of steel billets?

- The main factors that influence the strength of steel billets include the chemical composition of the steel, the heat treatment process, the presence of impurities and alloying elements, the cooling rate during the solidification process, and the mechanical processing and deformation of the billets.

- Q: What are the different types of steel billet forging defects?

- During the forging process, various steel billet forging defects may arise, each with its own causes and potential impact on the final forged product's quality and integrity. The common defects encompass the following: 1. Surface cracks, resulting from excessive heating or cooling, improper forging techniques, or the presence of impurities in the steel, manifest as cracks on the billet's surface. 2. Internal voids, caused by incomplete mold filling, inadequate venting, or trapped gases within the steel, form cavities or voids within the billet. 3. Inclusions, consisting of foreign materials or impurities within the billet, like non-metallic particles (e.g., oxides or sulfides) or metallic impurities (e.g., slag), can weaken the steel structure and diminish overall quality. 4. Segregation, which occurs during the cooling process, refers to the uneven distribution of alloying elements within the billet, leading to different mechanical properties in distinct areas of the steel and resulting in inconsistencies in the final product. 5. Dimensional inaccuracies, arising from improper tooling or die design, inadequate heating or cooling processes, or improper handling during forging, refer to deviations from the desired shape or size of the billet. 6. Grain structure abnormalities, influenced by factors such as improper heating or cooling rates, can weaken the steel and reduce its mechanical properties by altering the grain structure. To ensure the quality and reliability of the final forged product, it is crucial to detect and address these defects during the production process. Quality control measures, including non-destructive testing and visual inspections, can aid in identifying and rectifying these defects before delivering the finished product to the customer.

- Q: How are steel billets used in the production of pipes?

- Steel billets are melted and then cast into a solid form, which is then rolled or forged to form pipes of various sizes and shapes. These billets serve as the raw material for the pipe production process and are essential in ensuring the strength, durability, and structural integrity of the pipes.

- Q: How are steel billets used in the production of turbine blades?

- Turbine blades rely heavily on steel billets, which serve as a fundamental building block in their production. These billets, essentially semi-finished steel products, serve as the initial material for the manufacturing process. To commence, the selection of steel billets is a meticulous process, taking into account specific requirements such as composition, strength, and durability. Once chosen, the billets undergo a series of processing steps to transform them into turbine blades. The initial step involves subjecting the steel billets to high temperatures in a furnace, a process known as forging. This procedure enhances the malleability of the steel, making it easier to work with. Once heated, the billets are then shaped into turbine blades through the application of mechanical forces. Following the initial forging process, the turbine blades are refined through a range of machining operations. These operations encompass precision cutting, grinding, and drilling, all aimed at achieving the desired dimensions, surface finish, and aerodynamic profiles. Aside from shaping and refinement, steel billets also play a pivotal role in strengthening and ensuring the integrity of turbine blades. Through heat treatment processes like quenching and tempering, the billets are hardened and tempered, resulting in desired mechanical properties such as high strength and resistance to fatigue. Moreover, steel billets provide the necessary material properties to withstand the harsh operating conditions of turbines. They exhibit excellent corrosion resistance, a crucial attribute for blades operating in environments with high temperatures, pressure, and moisture. In summary, steel billets are indispensable in turbine blade production as they serve as the starting material, facilitate shaping and refinement, and offer the required strength and durability for these critical components in power generation.

- Q: What are the potential applications of steel billets in the food and beverage sector?

- Due to their unique properties, steel billets offer a wide range of potential applications in the food and beverage sector. One possible use is for constructing food processing equipment. Steel billets can be transformed into mixers, blenders, and conveyors, which are vital in the food processing industry. The exceptional strength and durability of steel make it an ideal material for withstanding the demanding conditions of food production. Another potential application is in the manufacturing of storage containers and tanks for food and beverage preservation. Steel billets can be converted into corrosion-resistant containers that are safe for storing liquids and food products. These containers are commonly utilized in breweries, wineries, and other beverage production facilities for storing ingredients, fermenting products, and finished goods. Additionally, steel billets can be employed in the construction of food transportation systems. Trucks and trailers that transport perishable goods often require sturdy and durable frames to ensure the products' safety and integrity. Steel billets can be utilized to manufacture these frames, providing a reliable and secure means of transportation for food and beverage products. Moreover, steel billets can be utilized in the construction of food service equipment, such as commercial ovens, grills, and fryers. These appliances necessitate materials that can withstand high temperatures and maintain their structural integrity over extended periods of use. Steel billets, with their exceptional heat resistance and strength, can fulfill these requirements, making them suitable for the foodservice industry. In conclusion, the potential applications of steel billets in the food and beverage sector are extensive. Whether it is for food processing equipment, storage containers, transportation systems, or food service equipment, steel billets provide the necessary strength, durability, and corrosion resistance to ensure the safety and efficiency of food production and distribution processes.

Send your message to us

120mm Steel Billets Q235 Q275 Q345 Professional Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords