Steel Billets Q195-Q235 20mnsi Q235 Q275 Q345 for Fireplace Billet Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billets Q195-Q235 20mnsi Q235 Q275 Q345 for Fireplace Billet Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

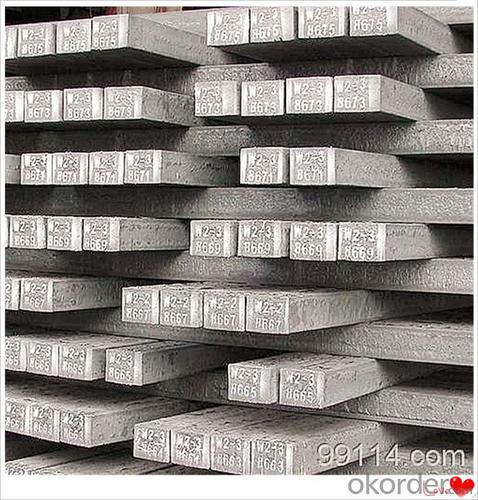

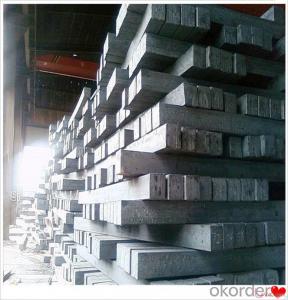

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the different types of cutting processes used for shaping steel billets?

- There are several different types of cutting processes used for shaping steel billets. These processes include: 1. Bandsaw cutting: Bandsaw cutting is a widely used method for cutting steel billets. It involves using a continuous band of toothed metal blade to cut through the billet. Bandsaws are known for their ability to cut through thick sections of steel quickly and accurately. 2. Abrasive cutting: Abrasive cutting involves using an abrasive wheel or disc to cut through the steel billet. This method is commonly used for cutting smaller billets or for cutting shapes and contours into the billet. Abrasive cutting is known for its versatility and ability to produce smooth and precise cuts. 3. Plasma cutting: Plasma cutting is a thermal cutting process that uses a high-velocity jet of ionized gas to melt and remove the steel from the billet. This method is often used for cutting thick sections of steel or for cutting intricate shapes. Plasma cutting is known for its speed and ability to produce clean cuts. 4. Waterjet cutting: Waterjet cutting is a process that uses a high-pressure jet of water to cut through the steel billet. In some cases, abrasive particles may be added to the water to enhance the cutting ability. Waterjet cutting is known for its ability to cut through thick sections of steel without creating heat-affected zones or distortion. 5. Laser cutting: Laser cutting involves using a high-powered laser beam to melt and vaporize the steel billet. The laser beam is guided by computer controls to cut the desired shape. Laser cutting is known for its precision and ability to cut intricate shapes with minimal distortion. These are just a few examples of the different types of cutting processes used for shaping steel billets. Each process has its own advantages and is chosen based on factors such as the size of the billet, the desired shape, and the required accuracy.

- Q: How are steel billets marked for identification and traceability?

- Steel billets are typically marked for identification and traceability through a variety of methods. These may include stamping or engraving unique identification numbers or codes directly onto the surface of the billets. Additionally, labels or tags with barcodes or QR codes containing relevant information may be attached to the billets. These identification marks and labels enable easy tracking and tracing of each billet throughout the manufacturing and supply chain processes, ensuring effective quality control and traceability.

- Q: Are steel billets used in the renewable energy sector?

- Certainly, the renewable energy sector makes use of steel billets. Steel, being a versatile material, finds its application in the construction of various components of renewable energy infrastructure. To illustrate, wind turbine towers, which are vital for generating wind energy, often employ steel billets in their production. This is because steel billets possess the necessary strength and durability to bear the immense weight and endure the harsh environmental conditions experienced by wind turbines. Furthermore, steel billets are also utilized in the development of solar power systems, including structures such as mounting structures and support frames for solar panels. These structures require a robust and dependable material like steel to ensure the stability and long-lasting nature of solar panels. Hence, it is evident that steel billets play an indispensable role in supporting and enabling the expansion of the renewable energy sector.

- Q: What are the main challenges in the quality control of steel billets?

- Several factors can affect the quality and performance of steel billets, posing significant challenges in their quality control. Here, we outline some key obstacles in this regard: 1. Chemical Composition: The accurate chemical composition of steel billets is pivotal in determining their strength, durability, and mechanical properties. However, ensuring consistent chemical composition is challenging due to variations in raw materials, melting processes, and the presence of impurities. 2. Homogeneity: It is crucial to achieve uniformity in the microstructure and composition throughout the steel billet. Inadequate mixing or non-uniform cooling can lead to inconsistencies, resulting in weak areas and uneven mechanical properties. 3. Defect Detection: Detecting and eliminating defects in steel billets is essential to prevent failures during subsequent processing and usage. Common defects include cracks, inclusions, segregation, porosity, and surface irregularities. However, accurately and promptly detecting these defects can be challenging due to their size, complexity, and location. 4. Dimensional Accuracy: Consistency in the dimensions and shape of steel billets is vital for their further processing and use in various applications. Maintaining precise dimensions requires controlling variables such as casting speed, cooling rates, and mold design. 5. Surface Quality: The condition of the surface of steel billets is critical for subsequent operations like rolling, forging, or machining. Ensuring a smooth, clean, and defect-free surface is challenging due to factors such as scale formation, oxidation, decarburization, and surface contamination during handling and storage. 6. Heat Treatment: Proper heat treatment is often necessary to achieve the desired mechanical properties in steel billets. However, controlling the heating and cooling rates, as well as the soaking times, can be challenging due to variations in equipment, temperature monitoring, and quenching techniques. 7. Traceability: Maintaining traceability and documentation throughout the production process is crucial for quality control. Tracking the origin of raw materials, process parameters, testing records, and certifications can be challenging, especially in complex supply chains. To address these challenges in the quality control of steel billets, a combination of advanced testing techniques, robust process controls, skilled personnel, and continuous improvement initiatives is necessary.

- Q: What are the different types of steel billet rolling processes?

- There are several different types of steel billet rolling processes that are used in the manufacturing industry. These processes include hot rolling, cold rolling, and warm rolling. Hot rolling is the most common and widely used method for producing steel billets. In this process, the steel billet is heated to a high temperature and then passed through a series of rolling mills to reduce its thickness and shape it into the desired form. The high temperature softens the steel and makes it more malleable, allowing it to be easily shaped and formed. Cold rolling, on the other hand, is a process where the steel billet is rolled at room temperature or slightly below. This process is typically used for producing steel billets with a higher level of precision and a smoother surface finish. Cold rolling also helps to improve the mechanical properties of the steel, making it stronger and more durable. Warm rolling is a combination of hot rolling and cold rolling. In this process, the steel billet is heated to a temperature that is lower than in hot rolling but higher than in cold rolling. The lower temperature helps to preserve the mechanical properties of the steel while still allowing for some shaping and forming. Each of these steel billet rolling processes has its own advantages and disadvantages. Hot rolling is the most cost-effective and efficient method, but it may result in some surface defects. Cold rolling provides a higher level of precision and surface finish, but it is more expensive and time-consuming. Warm rolling offers a balance between the two, but it may not be suitable for all applications. Overall, the choice of steel billet rolling process depends on various factors such as the desired shape and properties of the final product, the production volume, and the cost considerations.

- Q: What are the different methods of steel billet surface cleaning?

- There are several methods of steel billet surface cleaning, each with its own advantages and disadvantages. Some of the common methods include: 1. Shot Blasting: This method involves shooting small metallic or non-metallic particles at high velocity onto the surface of the billet. The impact of these particles removes any rust, scale, or surface contaminants. Shot blasting is an effective method for cleaning large surfaces quickly, but it can cause surface roughness and may not be suitable for all types of steel. 2. Acid Pickling: Acid pickling involves immersing the steel billet in an acid solution, typically hydrochloric or sulfuric acid, to remove scale and rust. The acid reacts with the surface contaminants, dissolving them and leaving a clean surface. Acid pickling is effective in removing stubborn scale and rust, but it requires careful handling of the corrosive acids and proper disposal of the waste. 3. Mechanical Cleaning: Mechanical cleaning methods involve using abrasive tools or brushes to physically scrub the surface of the billet. This can be done manually or using machinery. Mechanical cleaning is effective in removing loose contaminants and scale, but it may not be suitable for heavily rusted or stubbornly adhered contaminants. 4. High-Pressure Water Jetting: This method uses high-pressure water jets to clean the surface of the billet. The force of the water removes scale, rust, and other contaminants. High-pressure water jetting is environmentally friendly as it does not involve the use of chemicals, but it may not be as effective in removing heavy scale or rust. 5. Ultrasonic Cleaning: Ultrasonic cleaning involves immersing the steel billet in a tank filled with a cleaning solution and subjecting it to high-frequency ultrasonic vibrations. The vibrations create tiny bubbles in the cleaning solution, which implode on the surface of the billet, effectively removing contaminants. Ultrasonic cleaning is effective in removing even microscopic particles and can reach complex geometries, but it may not be suitable for large-scale cleaning operations. Each of these methods has its own strengths and limitations, and the choice of method depends on factors such as the type and condition of the surface contaminants, the time and cost constraints, and the desired surface finish.

- Q: How are steel billets used in the production of transmission components?

- Steel billets are an essential raw material used in the production of transmission components. These billets are semi-finished products that are typically obtained through the casting process. They are usually rectangular or square in shape and have a cross-sectional area that is larger than the final product. The production of transmission components involves shaping the steel billets into the desired forms. This is done through a series of processes like forging, rolling, or extrusion. Each of these processes is aimed at transforming the steel billets into specific shapes and sizes required for transmission components such as gears, shafts, bearings, and housings. Forging is a common method used to shape the steel billets. It involves applying heat to the billet and then using mechanical force to deform it into the desired shape. This process enhances the strength and durability of the transmission components. Rolling is another method used in the production of transmission components. In this process, the steel billets are passed through a series of rollers that gradually reduce their cross-sectional area. This helps to achieve the desired shape and dimensions of the components. Extrusion is also employed in certain cases, especially for producing complex shapes. In this process, the steel billets are forced through a die to obtain the desired form. This allows for the production of intricate transmission components such as splined shafts or valves. Once the steel billets have been shaped into the required forms, they undergo further machining processes like cutting, drilling, and grinding to achieve the final specifications. These components are then heat-treated and coated to enhance their strength, durability, and resistance to corrosion. Overall, steel billets play a crucial role in the production of transmission components by providing a versatile and reliable raw material that can be shaped into various forms. They ensure the transmission components possess the necessary strength, durability, and precision required for efficient and reliable operation in vehicles and machinery.

- Q: How are steel billets used in the production of railway tracks?

- Steel billets are the raw materials used in the production of railway tracks. They are heated, shaped, and rolled to form long, flat bars known as rails. These rails are then laid on the trackbed, forming the foundation for the tracks on which trains run.

- Q: What is the typical elongation of a steel billet?

- The typical elongation of a steel billet can vary depending on factors such as the specific grade of steel and the manufacturing process. However, a common range for elongation in steel billets is typically around 20-30%.

- Q: How do steel billets contribute to the manufacturing of industrial machinery?

- Steel billets play a crucial role in the manufacturing of industrial machinery. These billets are essentially semi-finished steel products that are formed into a specific shape and size. They serve as the raw material for producing various components and parts used in industrial machinery. Firstly, steel billets provide the necessary strength and durability required for industrial machinery. The high tensile strength and toughness of steel make it ideal for withstanding heavy loads, vibrations, and extreme conditions that machinery often encounters. By using steel billets, manufacturers can ensure that the machinery they produce is capable of withstanding these demanding conditions, thereby increasing its reliability and longevity. Secondly, steel billets can be easily molded and shaped into different forms, allowing for the production of complex and intricate components. Industrial machinery often requires precision-engineered parts that are tailored to specific functions and applications. Steel billets can be cast or forged into these intricate shapes, ensuring that the machinery operates with optimal efficiency and accuracy. Additionally, steel billets offer excellent machinability, meaning they can be easily cut, drilled, and shaped using various machining techniques. This makes it possible to create intricate details and tolerances required for the precise functioning of industrial machinery. The ability to machine steel billets with precision allows manufacturers to produce components that fit together seamlessly, minimizing any potential performance issues. Moreover, steel billets provide a cost-effective solution for manufacturing industrial machinery. Steel is readily available and has a relatively low cost compared to other materials. Its superior strength-to-weight ratio also allows manufacturers to design machinery that is lighter in weight without compromising its structural integrity. This not only reduces manufacturing costs but also makes the machinery more portable and easier to transport. Furthermore, steel billets offer excellent corrosion resistance, which is crucial for industrial machinery that operates in harsh environments. The protective oxide layer that forms on the surface of steel billets helps prevent rust and corrosion, ensuring that the machinery remains in optimal working condition even in challenging conditions. In conclusion, steel billets are essential in the manufacturing of industrial machinery due to their strength, durability, machinability, cost-effectiveness, and corrosion resistance. These properties enable manufacturers to produce reliable, precise, and long-lasting machinery that can withstand demanding industrial applications.

Send your message to us

Steel Billets Q195-Q235 20mnsi Q235 Q275 Q345 for Fireplace Billet Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords