Steel Billets Q235 China Q235 Q275 Q345 Hot selling Billet Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

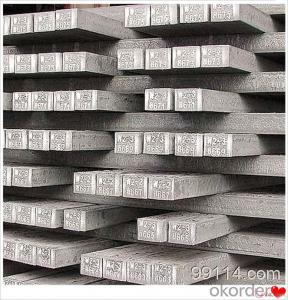

Steel Billets Q235 China Q235 Q275 Q345 Hot selling Billet Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the different types of cleaning equipment used for steel billets?

- Steel billets commonly undergo cleaning using various types of equipment. These include: 1. Shot blasting machines: These machines propel small metal or mineral particles at high speed onto the surface of the billets, effectively eliminating rust, scale, and other contaminants, resulting in a clean and smooth surface. 2. Ultrasonic cleaners: Through the use of high-frequency sound waves, ultrasonic cleaning agitates a cleaning solution, effectively removing dirt, oil, and other contaminants from the billets' surface. This method is particularly useful for stubborn or hard-to-reach contaminants. 3. Acid pickling tanks: By immersing the billets in an acidic solution, acid pickling dissolves rust, scale, and other contaminants. After pickling, rinsing and drying are usually carried out. 4. Power washers: Power washers, also known as pressure washers, employ a high-pressure water spray to eliminate dirt, oil, and other contaminants from the billets' surface. This method is particularly effective for larger or heavier billets. 5. Mechanical cleaning brushes: Mechanical cleaning brushes, including wire brushes or abrasive pads, are commonly employed to manually scrub the billets' surface, removing loose dirt, rust, or scale. Typically used in conjunction with other cleaning methods. In determining the appropriate cleaning equipment for steel billets, factors such as the extent and type of contaminants, desired level of cleanliness, and the size and shape of the billets need to be considered. Different combinations of these cleaning methods may be utilized to achieve the desired outcome.

- Q: What are the different types of steel billet rolling processes?

- There are several different types of steel billet rolling processes that are used in the manufacturing industry. These processes include hot rolling, cold rolling, and warm rolling. Hot rolling is the most common and widely used method for producing steel billets. In this process, the steel billet is heated to a high temperature and then passed through a series of rolling mills to reduce its thickness and shape it into the desired form. The high temperature softens the steel and makes it more malleable, allowing it to be easily shaped and formed. Cold rolling, on the other hand, is a process where the steel billet is rolled at room temperature or slightly below. This process is typically used for producing steel billets with a higher level of precision and a smoother surface finish. Cold rolling also helps to improve the mechanical properties of the steel, making it stronger and more durable. Warm rolling is a combination of hot rolling and cold rolling. In this process, the steel billet is heated to a temperature that is lower than in hot rolling but higher than in cold rolling. The lower temperature helps to preserve the mechanical properties of the steel while still allowing for some shaping and forming. Each of these steel billet rolling processes has its own advantages and disadvantages. Hot rolling is the most cost-effective and efficient method, but it may result in some surface defects. Cold rolling provides a higher level of precision and surface finish, but it is more expensive and time-consuming. Warm rolling offers a balance between the two, but it may not be suitable for all applications. Overall, the choice of steel billet rolling process depends on various factors such as the desired shape and properties of the final product, the production volume, and the cost considerations.

- Q: How are steel billets used in the manufacturing of marine equipment?

- Steel billets are used in the manufacturing of marine equipment as they serve as raw materials that are subsequently forged or rolled into various components such as ship hulls, propeller shafts, and engine parts. These billets undergo a series of processes such as heating, rolling, and shaping to create the necessary strength and durability required for marine applications.

- Q: What is the typical composition of steel billets?

- The typical composition of steel billets consists of primarily iron and carbon, with small amounts of other elements such as manganese, silicon, and sulfur.

- Q: Are steel billets subject to any heat treatment processes?

- Yes, steel billets are subject to heat treatment processes. Heat treatment processes such as annealing, normalizing, quenching, and tempering can be applied to steel billets to enhance their mechanical properties and improve their overall performance.

- Q: How are steel billets used in the manufacturing of industrial valves?

- Industrial valves rely heavily on steel billets as a vital element in their production. These valves are critical devices utilized to regulate the movement of fluids and gases in a wide range of industrial operations. Steel billets, which are partially processed metal products, play a crucial role in the creation of these valves. The manufacturing process for industrial valves typically involves multiple stages, including forging, machining, and assembly. Steel billets are primarily employed during the forging phase of valve production. Forging is the technique of shaping metal by applying localized compressive forces using dies or hammers. Steel billets are heated to a specific temperature and then subjected to intense pressure, causing them to take on the desired shape. The use of steel billets in the forging of valves presents several advantages. Firstly, steel is renowned for its exceptional strength and durability, making it an ideal material for valves operating under high-pressure conditions. Steel billets supply the necessary raw material to create sturdy and dependable valve components. Furthermore, steel billets can be easily molded and shaped during the forging process. This allows manufacturers to craft intricate valve designs with precision and accuracy. The versatility of steel billets facilitates the production of valves in various sizes, shapes, and configurations to meet specific industrial requirements. Moreover, steel billets can undergo heat treatment after forging to enhance their mechanical properties. Heat treatment methods such as quenching and tempering can greatly improve the hardness, strength, and wear resistance of valve components. This ensures that the valves can withstand demanding operating conditions and deliver optimal performance over an extended period. In conclusion, the utilization of steel billets is indispensable in the manufacturing of industrial valves. These billets provide the raw material necessary for forging robust valve components, offering strength, durability, and versatility. Leveraging steel billets enables the production of high-quality valves capable of efficiently controlling the flow of fluids and gases in industrial processes.

- Q: How do steel billets contribute to the manufacturing of aerospace components?

- Steel billets play a crucial role in the manufacturing of aerospace components. These billets are semi-finished products that are used as a starting material in the fabrication of various aerospace parts. One of the primary ways steel billets contribute to the manufacturing of aerospace components is through their versatility. Steel is known for its exceptional strength, durability, and resistance to corrosion, making it an ideal material for aerospace applications. Billets made from high-quality steel provide the necessary foundation for the production of components that can withstand the extreme conditions experienced during aerospace operations. Steel billets are often used in the production of critical aerospace parts such as engine components, landing gear, structural frames, and fasteners. The billets are first heated and then subjected to various forming and machining processes. These processes, such as forging, rolling, and extrusion, help shape the steel billets into the desired components, ensuring they meet the stringent requirements for strength, precision, and weight reduction demanded by the aerospace industry. Moreover, steel billets offer excellent design flexibility. They can be easily machined and shaped into complex geometries, allowing manufacturers to create intricate aerospace components with precise tolerances. This flexibility enables the production of lightweight yet strong parts, contributing to the overall weight reduction of aircraft and enhancing fuel efficiency. Furthermore, steel billets offer superior metallurgical properties. Through proper heat treatment and alloying techniques, the mechanical properties of the steel can be tailored to meet specific aerospace requirements. This allows manufacturers to achieve the desired balance between strength, stiffness, and toughness in the final components, ensuring they can withstand the high-stress environments encountered in aerospace applications. In conclusion, steel billets are an indispensable part of the manufacturing process for aerospace components. Their versatility, strength, design flexibility, and metallurgical properties make them an ideal starting material for the production of critical parts in the aerospace industry. By utilizing steel billets, manufacturers can ensure the production of high-quality, reliable, and durable components that meet the rigorous demands of the aerospace sector.

- Q: What are the different surface treatments for improved formability in steel billets?

- To enhance the formability of steel billets, various surface treatments can be employed. These treatments aim to increase the steel's ability to be shaped and formed without experiencing cracks or fractures. One effective method for enhancing formability is the utilization of lubricants or coatings. These substances aid in reducing friction between the steel and the forming tools, facilitating the shaping of the billets without causing any damage. Lubricants can be administered in the form of oils, greases, or solid films, and they can be utilized in both hot and cold forming procedures. Another technique for improving formability is shot peening, which entails bombarding the steel's surface with small steel or ceramic particles that possess high velocity. This process creates a compressive stress layer on the surface, effectively preventing crack initiation and propagation during the forming process. Additionally, shot peening can enhance the steel's fatigue resistance. In certain instances, heat treatment can be employed to enhance formability. This involves heating the steel to a specific temperature and rapidly cooling it. This process, known as quenching and tempering, can modify the steel's microstructure, increasing its ductility and making it easier to shape. Heat treatment also aids in relieving residual stresses in the steel, thereby improving formability. Lastly, surface coatings can be applied to steel billets to enhance formability. These coatings act as a protective barrier between the steel and the forming tools, reducing friction and preventing wear. Various methods, such as electroplating, thermal spraying, or chemical vapor deposition, can be utilized to apply these coatings. In conclusion, there exist several surface treatments that can be employed to enhance formability in steel billets. These treatments encompass the application of lubricants or coatings, shot peening, heat treatment, and surface coatings. Each treatment offers unique advantages and can be utilized based on the specific requirements of the forming process.

- Q: How do steel billets contribute to the aerospace industry?

- Steel billets play a crucial role in the aerospace industry by providing the necessary raw material for manufacturing various components and structures used in aircraft. These billets, which are semi-finished metal forms, are typically produced through a process called continuous casting, where molten steel is poured into a mold to create a solid billet shape. Once the steel billets are formed, they are further processed into different aerospace components through various manufacturing techniques such as forging, machining, and heat treatment. These processes allow the steel billets to be shaped into specific forms, such as engine components, landing gear parts, structural frames, and other critical aerospace components. The use of steel billets in the aerospace industry offers several advantages. Firstly, steel is known for its high strength, durability, and excellent mechanical properties, making it a suitable material for applications where safety and reliability are of utmost importance, such as in the aerospace sector. Steel billets can withstand extreme temperatures, pressure, and stress, making them ideal for critical parts that need to perform under demanding conditions. Additionally, steel billets provide cost-effectiveness and versatility in manufacturing. Steel is widely available, making it a relatively affordable material compared to other metals used in the aerospace industry. Moreover, the ability to shape and process steel billets into various forms and sizes allows for flexibility in designing and producing aerospace components, ensuring they meet the specific requirements and standards of aircraft manufacturers. Another key contribution of steel billets to the aerospace industry is their compatibility with advanced manufacturing technologies. Steel can be easily machined, welded, and joined, enabling the integration of complex features and structures in aerospace components. This compatibility with modern manufacturing techniques allows for the production of lightweight, yet robust, parts, contributing to overall fuel efficiency and improved performance of aircraft. In conclusion, steel billets are vital to the aerospace industry as they provide the necessary raw material for manufacturing critical components and structures used in aircraft. Their high strength, durability, cost-effectiveness, and compatibility with advanced manufacturing technologies make steel billets an essential ingredient in building safe, reliable, and efficient aerospace systems.

- Q: What is the lifespan of steel billets?

- The durability of steel billets can be influenced by several factors, including the steel quality, storage conditions, and specific usage. When properly stored and maintained, steel billets can have a considerably long lifespan. Under favorable circumstances, these billets can endure for numerous years without notable deterioration. Nevertheless, if exposed to harsh environmental elements like moisture, extreme temperatures, or corrosive substances, their lifespan may be significantly shortened. It is crucial to handle and store steel billets with care to minimize any potential harm and guarantee their prolonged existence.

Send your message to us

Steel Billets Q235 China Q235 Q275 Q345 Hot selling Billet Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords