Steel Billet Bar Q235 Q275 Q345 for Coke Oven Door

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

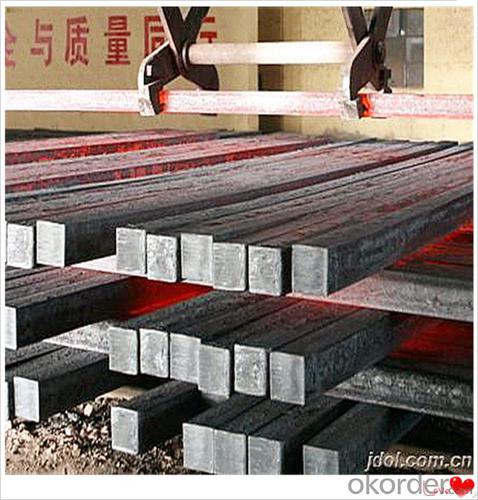

Steel Billet Bar Q235 Q275 Q345 for Coke Oven Door

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the different types of surface defect detection equipment for steel billets?

- There are various types of surface defect detection equipment available for steel billets. These equipment are designed to identify and analyze defects on the surface of steel billets, ensuring that only high-quality products are used in various applications. Some of the different types of surface defect detection equipment for steel billets include: 1. Ultrasonic Testing (UT): UT equipment uses sound waves to detect surface defects in steel billets. It emits high-frequency sound waves that penetrate the material and reflect back when they encounter any surface irregularities. This method helps identify cracks, voids, and other defects on the surface. 2. Eddy Current Testing (ECT): ECT equipment uses electromagnetic induction to detect surface defects in steel billets. It works by passing an alternating current through a coil, generating a magnetic field that interacts with the conductive material of the billet. Any surface defect or irregularity will cause a change in the magnetic field, which can be measured and analyzed. 3. Magnetic Particle Inspection (MPI): MPI equipment uses magnetic fields and iron particles to detect surface defects in steel billets. The billet is magnetized, and iron particles are applied to its surface. These particles will gather around any surface defect, creating visible indications that can be easily identified and evaluated. 4. Visual Inspection: Visual inspection equipment involves the use of cameras, lasers, and other optical devices to detect surface defects in steel billets. These devices capture images or videos of the billet's surface and allow inspectors to identify any irregularities or defects visually. 5. Thermographic Testing: Thermographic equipment uses infrared cameras to detect surface defects in steel billets by measuring the temperature variations. Any defect will cause a difference in heat transfer, resulting in distinct thermal patterns that can be detected and analyzed. 6. X-ray Inspection: X-ray inspection equipment uses X-ray radiation to penetrate the steel billet and detect internal and surface defects. It provides detailed images that allow inspectors to identify cracks, voids, and other defects that are not visible to the naked eye. Overall, these different types of surface defect detection equipment for steel billets offer a range of methods to ensure the quality and integrity of the billets, enabling manufacturers to deliver high-quality steel products to various industries.

- Q: What are the main safety considerations when handling steel billets?

- The main safety considerations when handling steel billets include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Proper lifting techniques should be used to prevent strains and back injuries when moving heavy billets. Additionally, ensuring a well-organized and clutter-free work area, as well as proper storage and stacking of the billets, can help prevent accidents and injuries.

- Q: What are the different types of surface finishes available for steel billets?

- There are several different types of surface finishes available for steel billets, each serving a specific purpose and offering unique characteristics. Some of the most common surface finishes for steel billets include: 1. Hot Rolled: This is the most basic surface finish, achieved by heating the steel billet above its recrystallization temperature and then rolling it to the desired shape and size. Hot rolled steel billets have a rough and scaled surface, which is suitable for applications where aesthetics are not a primary concern. 2. Cold Rolled: This surface finish is obtained by further processing the hot rolled billets through a series of cold rolling processes. Cold rolled steel billets have a smoother and more refined surface, with tighter tolerances and improved dimensional accuracy. 3. Pickled and Oiled: This surface finish involves removing any rust, scale, or mill scale from the steel billets by immersing them in an acidic solution, commonly known as pickling. After pickling, the steel billets are oiled to provide temporary corrosion protection. This finish is ideal for applications where cleanliness and corrosion resistance are crucial. 4. Galvanized: Galvanizing is a surface finishing process that involves coating the steel billets with a layer of zinc to provide enhanced corrosion resistance. This finish is particularly suitable for outdoor applications or environments with high humidity, where the steel needs protection against rust and corrosion. 5. Electroplated: Electroplating is a process where a thin layer of metal, such as nickel or chromium, is deposited onto the steel billets through an electrochemical reaction. This surface finish provides improved aesthetics, enhanced corrosion resistance, and can also offer specific functional properties, such as hardness or wear resistance. 6. Powder Coated: Powder coating is a surface finishing technique where a dry powder is electrostatically applied to the steel billets and then cured under heat to form a durable and protective coating. This finish offers excellent corrosion resistance, impact resistance, and a wide range of color options, making it popular in architectural and decorative applications. 7. Anodized: Anodizing is a surface treatment commonly used for aluminum, but it can also be applied to steel billets. This process involves creating an oxide layer on the surface of the steel by subjecting it to an electrolytic process. Anodized steel billets exhibit improved corrosion resistance, increased hardness, and can be dyed in various colors for aesthetic purposes. These are just a few examples of the different types of surface finishes available for steel billets. The choice of finish depends on the specific requirements of the application, including aesthetics, corrosion resistance, durability, and functional properties.

- Q: What are the main factors affecting the dimensional tolerances of steel billets?

- The dimensional tolerances of steel billets can be influenced by various factors. One of the main factors is the manufacturing process itself. The method used to produce the billets, such as casting or hot rolling, can impact the final dimensions. For example, casting processes may introduce variations in the cooling rate, which can affect the overall shape and size of the billets. Another important factor is the initial quality of the raw material. The composition and homogeneity of the steel used to produce the billets can contribute to dimensional variations. Impurities or uneven distribution of alloying elements can lead to inconsistencies in the size and shape of the billets. The temperature during the manufacturing process is also a significant factor. High temperatures can cause thermal expansion, leading to dimensional changes in the billets. Cooling rates and control of the cooling process are critical to maintaining the desired tolerances. The design and condition of the equipment used in the manufacturing process can also impact the dimensional tolerances. Proper maintenance and calibration of machinery are essential to ensure consistent and accurate production. Finally, external factors such as handling and transportation can affect the dimensional tolerances of steel billets. Improper handling or rough transportation conditions can cause physical deformations or damage to the billets, leading to variations in their dimensions. Overall, the dimensional tolerances of steel billets are influenced by factors such as the manufacturing process, raw material quality, temperature control, equipment condition, and handling and transportation practices. Attention to these factors is crucial to achieving the desired dimensional accuracy in steel billets.

- Q: What are the main surface finishes available for steel billets?

- The main surface finishes available for steel billets include hot rolled, cold rolled, and coated finishes.

- Q: What are the different methods of steel billet surface finishing?

- In the industry, various techniques are commonly employed for the surface finishing of steel billets. These techniques comprise: 1. Shot blasting: Shot blasting is a prevalent method utilized to cleanse and prepare steel billets for subsequent processing. It entails propelling abrasive particles onto the billet surface at high velocities. This process effectively eliminates rust, scale, and impurities, resulting in a pristine and smooth finish. 2. Grinding: Grinding is an alternative approach employed to attain a smooth and uniform surface finish on steel billets. It involves the utilization of abrasive wheels or belts to remove material from the billet surface. Depending on the billet size and requirements, grinding can be performed manually or using automated machinery. 3. Polishing: Polishing is generally employed to achieve a glossy and reflective finish on steel billets. This process entails the use of polishing compounds and buffing wheels to refine the surface and enhance its appearance. Polishing is commonly employed for decorative purposes or when a high-quality finish is desired. 4. Acid pickling: Acid pickling is a technique employed to eliminate oxide scale or rust from the surface of steel billets. It involves immersing the billets in an acid solution, such as hydrochloric acid, to dissolve impurities. Acid pickling is an effective method for achieving a uniform and clean surface finish on steel billets. 5. Passivation: Passivation is frequently employed to enhance the corrosion resistance of steel billets. It involves immersing the billets in a passivating solution, typically a mixture of nitric acid and water, to eliminate surface contaminants and facilitate the formation of a protective oxide layer. Passivation aids in preventing rust formation and prolonging the lifespan of steel billets. In conclusion, the selection of a suitable method for steel billet surface finishing depends on the desired finish, billet size and shape, and specific application requirements. Each method offers unique advantages and considerations. Therefore, careful consideration is crucial in selecting the appropriate technique to achieve the desired surface finish.

- Q: What are the advantages of using steel billets in construction?

- There are several advantages of using steel billets in construction: 1. Strength and Durability: Steel billets are known for their high strength and durability, making them ideal for construction purposes. They can withstand heavy loads and extreme weather conditions, ensuring the longevity and stability of the structure. 2. Versatility: Steel billets can be molded and shaped into various forms, allowing for flexibility in design and construction. This versatility makes them suitable for a wide range of applications, from beams and columns to framing and foundations. 3. Cost-effectiveness: Despite the initial cost of steel billets being higher than other construction materials, their long-term benefits outweigh the investment. Steel is low maintenance, doesn't require frequent repairs or replacements, and offers excellent fire resistance, reducing insurance costs. 4. Sustainability: Steel is a highly sustainable material due to its recyclability. Steel billets can be recycled and reused without losing their properties, reducing the demand for virgin materials and minimizing environmental impact. 5. Speed of construction: Steel billets are pre-fabricated, meaning they are manufactured off-site and then transported to the construction site. This significantly reduces construction time and allows for faster completion of projects. 6. Resistance to pests and rot: Unlike wood, steel billets are not susceptible to termites, pests, or rot. This eliminates the need for chemical treatments or regular inspections, saving both time and money. 7. Design flexibility: Steel billets offer a wide range of design possibilities, enabling architects and engineers to create unique and aesthetically pleasing structures. The ability to span large distances without the need for additional support columns allows for open floor plans and creative architectural designs. In summary, the advantages of using steel billets in construction include their strength, durability, versatility, cost-effectiveness, sustainability, speed of construction, resistance to pests and rot, and design flexibility. These factors make steel billets an excellent choice for various construction projects, ensuring sturdy and long-lasting structures.

- Q: How are steel billets used in the manufacturing of hydraulic components?

- Steel billets are commonly used in the manufacturing of hydraulic components as they serve as the raw material for shaping and forming various parts such as cylinders, pistons, and valves. These billets are heated and then subjected to various mechanical processes like forging, rolling, or extrusion to achieve the desired shape and size. The resulting hydraulic components made from steel billets offer high strength, durability, and resistance to pressure, making them suitable for use in hydraulic systems that require reliable and efficient operation.

- Q: How do steel billets contribute to the manufacturing of telecommunications devices?

- The manufacturing of telecommunications devices heavily relies on steel billets in several ways. Firstly, steel billets are utilized as raw materials for producing various components essential for telecommunications devices. These components comprise structural frames, housing, brackets, and mounts, among others. Steel's strength and durability make it an ideal choice for these parts as they must endure harsh environments and provide stability to the devices. Additionally, steel billets find extensive use in the production of transmission towers and antenna masts, which are crucial for efficient signal transmission and reception in the telecommunications industry. These towers and masts necessitate sturdiness and the ability to support heavy equipment to ensure uninterrupted communication. Steel, with its high strength and load-bearing capacity, is an optimal material for fulfilling these requirements. Moreover, steel billets are also employed in manufacturing cable trays and conduits, which are indispensable for organizing and safeguarding various cables used in telecommunications devices. These cable management systems guarantee proper routing and protection of cables from external factors like moisture, heat, and physical damage. Steel's resistance to corrosion and its ability to withstand extreme conditions make it an excellent choice for fulfilling these purposes. Apart from its physical properties, steel billets contribute to the manufacturing of telecommunications devices due to their cost-effectiveness. Steel is widely available and relatively inexpensive compared to other materials, making it a preferred choice for manufacturers. Its versatility and ease of fabrication further enhance the efficient production of telecommunications devices. In conclusion, steel billets play a vital role in the manufacturing of telecommunications devices by providing raw materials for various components, supporting infrastructure, and ensuring efficient cable management. Their strength, durability, cost-effectiveness, and availability make them an indispensable material in the telecommunications industry.

- Q: What are the weight ranges of steel billets?

- The weight of steel billets can vary based on the industry's specific requirements and standards. Generally, steel billets can weigh anywhere from a few kilograms to several metric tons. The weight of a steel billet is determined by factors like its dimensions, intended application, and production process. Smaller steel billets, used in construction or manufacturing, typically weigh between 1 to 10 kilograms. Conversely, larger steel billets, commonly utilized in heavy machinery or infrastructure projects, can weigh anywhere from 10 to 100 metric tons or potentially more. It is important to note that these weight ranges are approximate estimates and may differ depending on the particular industry requirements and production capabilities.

Send your message to us

Steel Billet Bar Q235 Q275 Q345 for Coke Oven Door

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords