Steel Billets and Steel Raw Materials Q235 Q275 Q345 New Design

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

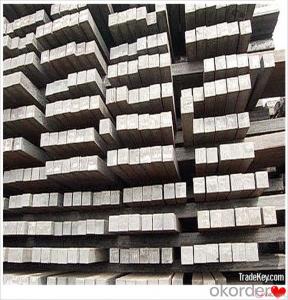

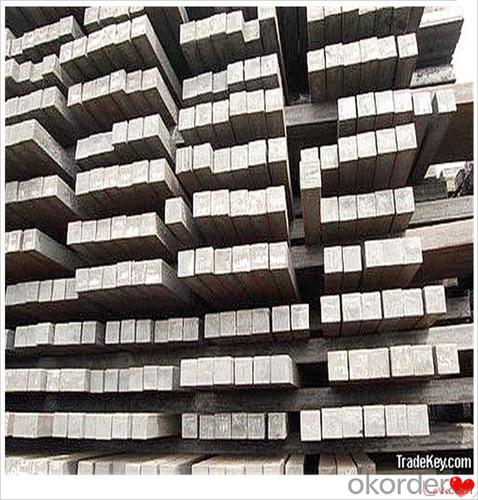

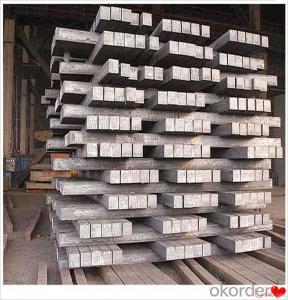

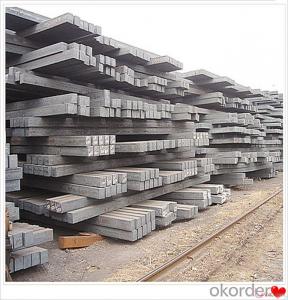

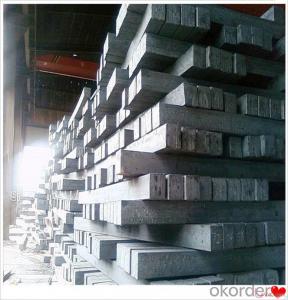

Steel Billets and Steel Raw Materials Q235 Q275 Q345 New Design

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets used in the manufacturing of valves and fittings?

- Valves and fittings rely on steel billets, an essential raw material, for their production. These billets are solid steel forms, cast into specific shapes and sizes. The manufacturing process starts by heating the steel billets to a high temperature and passing them through rolling mills to achieve the desired form. This process refines the grain structure, enhancing the steel's strength, ductility, and overall quality. After shaping, the billets undergo further processing and machining to create various valve and fitting components, including bodies, bonnets, stems, and other essential parts. Precise machining ensures accurate dimensions and smooth surfaces, enabling proper assembly and functioning. Steel billets also provide crucial strength and durability to valves and fittings, as they are made from high-quality steel. This ensures that the final products can withstand the harsh operating conditions, pressure, and temperature variations they may encounter. Moreover, steel billets offer versatility in manufacturing, allowing the production of different types of valves and fittings, such as gate valves, ball valves, butterfly valves, and pipe fittings. This flexibility enables manufacturers to meet diverse industry requirements. In summary, steel billets serve as the primary raw material in the production of valves and fittings. Shaping, processing, and machining these billets result in high-quality components that offer strength, durability, and precision in the final products.

- Q: How are steel billets inspected for internal and surface defects?

- Steel billets are inspected for internal and surface defects through a variety of methods to ensure their quality and integrity. For internal defects, one common method is ultrasonic testing (UT), where high-frequency sound waves are transmitted through the billet. Any discontinuities or defects within the billet will cause the sound waves to reflect back to the receiver, indicating the presence of a flaw. UT can detect defects such as cracks, voids, and inclusions within the billet. Another technique used for inspecting internal defects is magnetic particle inspection (MPI). This method involves applying a magnetic field to the billet and then coating it with iron particles. Any internal defects or cracks will disrupt the magnetic field, causing the iron particles to gather at these locations and become visible under proper lighting conditions. When it comes to surface defects, visual inspection is typically the first step. Trained inspectors visually examine the billet for any visible irregularities, such as cracks, pits, scratches, or deformities. They may also use specialized equipment like magnifying glasses or microscopes to ensure a thorough inspection. In addition to visual inspection, surface defects can also be detected using other non-destructive testing techniques. One common method is dye penetrant testing (PT), where a colored liquid dye is applied to the billet's surface. The dye seeps into any surface defects and is later removed, leaving behind a visible indication of the defect. This method is particularly effective in detecting surface cracks or discontinuities. Another technique used for surface defect inspection is eddy current testing (ECT). ECT relies on the principle that a fluctuating magnetic field induces electrical currents in conductive materials like steel. Any surface defects or irregularities will disrupt the induced currents, which can be detected by monitoring changes in the electrical properties of the billet. ECT is commonly used to detect surface cracks, pits, or variations in thickness. Overall, a combination of these inspection methods allows for a comprehensive evaluation of steel billets, ensuring that both internal and surface defects are detected and addressed before the billets are further processed or used in various applications.

- Q: How are steel billets used in the manufacturing of pressure vessels?

- Steel billets are an essential component in the manufacturing of pressure vessels. These billets, which are semi-finished metal products, are typically made through a process called casting or extrusion. They are shaped into a solid square or rectangular form, ensuring a consistent and uniform material for further processing. To start the manufacturing process, the steel billets are heated to a specific temperature to make them more malleable and easier to work with. Once heated, they are placed into a forging machine, where they are subjected to intense pressure and shaping. This forging process helps to eliminate any defects or inconsistencies in the billet's structure, resulting in a stronger and more durable material. After forging, the steel billets are further processed through various techniques, such as rolling or machining, to achieve the desired dimensions and shape required for pressure vessel fabrication. These techniques help to refine the billet's surface finish and improve its mechanical properties. Once the billets have been shaped and processed, they are cut into smaller sections, which serve as the building blocks for pressure vessel construction. These sections are then welded together to form the shell of the vessel, ensuring a tight and secure seal to contain the high-pressure fluids or gases. The use of steel billets in pressure vessel manufacturing is crucial because of their superior strength, durability, and resistance to high-pressure environments. The uniformity and consistency of the billets provide a reliable material for fabricating vessels that can withstand extreme conditions and ensure the safety and integrity of the contents within. In summary, steel billets play a vital role in the manufacturing of pressure vessels as they provide the foundation for constructing the vessel's shell. Through a series of heating, forging, and processing techniques, the billets are transformed into strong and durable sections that are then welded together to form the final vessel. The use of steel billets ensures the structural integrity and reliability of pressure vessels, making them suitable for a wide range of industrial applications.

- Q: How are steel billets used in the manufacturing of shafts?

- Steel billets are used in the manufacturing of shafts as the starting material. The billets are heated and then shaped and machined into the desired shape and size of the shaft. This process ensures that the shafts are strong, durable, and able to withstand the required loads and stresses in various applications.

- Q: Are steel billets magnetic?

- Indeed, steel billets possess magnetic qualities. As an alloy predominantly consisting of iron, steel constitutes a ferromagnetic substance, rendering it capable of magnetization. Consequently, steel exhibits magnetic properties. Given that steel billets are solid blocks or bars composed of steel, they retain the magnetic characteristics inherent to their constituent material.

- Q: What are the different types of non-destructive testing methods used for steel billets?

- Some of the different types of non-destructive testing methods used for steel billets include ultrasonic testing, magnetic particle testing, dye penetrant testing, eddy current testing, and visual inspection.

- Q: What are the different types of steel billet inspection equipment?

- There are several different types of steel billet inspection equipment used in the manufacturing industry. These equipment are specifically designed to ensure the quality and integrity of the steel billets before they are further processed. 1. Ultrasonic Testing (UT) Equipment: This type of equipment uses high-frequency sound waves to detect internal flaws or defects in the steel billets. It can identify cracks, voids, and other imperfections that may affect the strength and performance of the final product. 2. Magnetic Particle Inspection (MPI) Equipment: MPI equipment uses a magnetic field and specially formulated particles to identify surface and near-surface defects in the steel billets. It can detect cracks, seams, and other imperfections that may not be visible to the naked eye. 3. Eddy Current Testing (ECT) Equipment: ECT equipment uses electromagnetic induction to detect surface cracks and defects in the steel billets. It can identify variations in electrical conductivity caused by localized defects or changes in material properties. 4. Visual Inspection Equipment: Visual inspection equipment includes tools such as magnifying glasses, microscopes, and cameras to visually examine the steel billets for surface defects, irregularities, or other visual anomalies. This type of equipment is often used in conjunction with other inspection methods for a comprehensive analysis. 5. Dimensional Measurement Equipment: This type of equipment is used to measure the dimensional accuracy and consistency of the steel billets. It includes tools such as calipers, micrometers, and laser scanners to ensure that the billets meet the required specifications and tolerances. 6. Surface Roughness Measurement Equipment: Surface roughness measurement equipment is used to quantify the surface finish of the steel billets. It uses a stylus or laser to measure the irregularities on the surface, providing important information about the billet's suitability for further processing. 7. X-ray Testing Equipment: X-ray equipment uses electromagnetic radiation to penetrate the steel billets and detect internal defects such as cracks, voids, or inclusions. This method is particularly effective for larger billets or when a comprehensive assessment of the internal structure is required. These are some of the commonly used steel billet inspection equipment in the manufacturing industry. Each type of equipment plays a crucial role in ensuring that the steel billets meet the required quality standards and are suitable for further processing into various end products.

- Q: How are steel billets used in the manufacturing of chemical processing equipment?

- Steel billets are used in the manufacturing of chemical processing equipment as raw material for forging or casting various components such as valves, pumps, heat exchangers, and reactors. These billets are shaped, machined, and treated to meet the specific requirements of the equipment, ensuring strength, durability, and resistance to corrosion and high temperatures.

- Q: How are steel billets used in the production of shafts?

- Shafts require steel billets as an indispensable component for their production. These billets are semi-finished products that serve as the initial stage for diverse manufacturing processes. In the case of shaft production, steel billets serve as the raw material from which the shafts are formed. The process commences by heating the steel billets to a specific temperature, typically within a furnace. This heating procedure, referred to as "hot working," is of utmost importance as it renders the steel more pliable and easier to mold. Once the billet attains the desired temperature, it is subsequently transferred to either a forging press or a rolling mill. During the forging process, the heated billet undergoes high pressure and is shaped using specialized dies to achieve the desired dimensions for the shaft. This method permits precise control over the shape, size, and surface finish of the shaft. On the contrary, the rolling process entails the billet passing through a sequence of rollers that gradually shape it into a cylindrical form. Rolling is frequently employed for shafts necessitating a consistent cross-section along their length. Following the initial shaping process, the shafts go through additional steps such as heat treatment, machining, and finishing to fulfill the specific requirements of their intended applications. Heat treatment assists in enhancing the mechanical properties of the shaft, rendering it stronger, more durable, and resistant to wear. Subsequently, machining processes such as turning, milling, or grinding are conducted to achieve precise dimensions, smooth surfaces, and accurate tolerances. Altogether, steel billets occupy a pivotal role in the production of shafts as they serve as the starting point for the shaping processes imperative in creating these crucial components. Through meticulous manipulation and refinement, steel billets metamorphose into high-quality shafts utilized in a myriad of industries, including automotive, aerospace, manufacturing, and numerous others.

- Q: How are steel billets straightened after rolling or forging?

- Steel billets are straightened after rolling or forging through a process called straightening, which involves applying pressure or tension to the billets. This can be done using hydraulic presses, roller straighteners, or heat treatment methods, which help to remove any deformities or bends in the billets and ensure they are straight and ready for further processing.

Send your message to us

Steel Billets and Steel Raw Materials Q235 Q275 Q345 New Design

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords